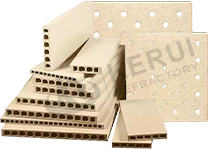

Kerui Refractory Bricks for Sale

Alumina Silica Series Brick

Magnesia Series Bricks

Special Brick

Silicon Carbide Series Brick

SiC: 66-80%;

C.C.S.: 220-580MPa;

Bulk Density: 2.72-2.80g/cm³;

Kerui Insulation Bricks for Sale

Al2O3: ≥48%;

Classification Temp: 1250-1350℃;

Bulk Density: 0.8-1.2g/cm³;

Al2O3: 42-72%;

Classification Temp: 1300-1450℃;

Bulk Density: 0.55-1.1g/cm³;

Kerui Monolithic Refractory Products

Refractory Cement

Al2O3: 50-52%;

Al2O3: 68-71%;

Al2O3: 77-80%;

Al2O3: 50-80%;

Refractory Castable

Refractory Mortar