Magnesia Refractory Brick

Magnesia refractory brick has unmatched durability, excellent heat resistance, and superior corrosion protection. These bricks are ideal for high-temp industries such as steel, cement, glass, and non-ferrous metal production. Kerui provides 5+ types of high-quality bricks and complete refractory solutions to meet your needs. We have offered bricks to 1000+ customers over the world and these customers have good reviews to us.

- Free Sample:

- Available

- Document:

- Certificates Supporting

- Performance Test:

- Support

- Shipment:

- 7-35 working days

Specification Data of Magnesia Refractory Bricks

Kerui Refractory offers not only high-purity common magnesia bricks but also a variety of composite magnesia bricks, which are designed to meet different industrial needs. In particular, the parameters of the high-purity magnesia bricks are shown here, so that customers can better understand their technical specifications and make informed decisions. Moreover, these detailed parameters reflect Kerui’s commitment to quality and transparency.

| Item | M-98 | M-97A | M-97B | M-95 | M-91 | |

|---|---|---|---|---|---|---|

| MgO, % | ≥ | 97.5 | 97.0 | 96.5 | 95.0 | 91.0 |

| SiO2, % | ≤ | 1.00 | 1.20 | 1.50 | 2.00 | / |

| CaO, % | ≤ | / | / | / | 2.00 | 3.00 |

| Apparent Porosity, % | ≤ | 16 | 16 | 18 | 16 | 18 |

| Bulk Density, g/cm³ | ≥ | 3.00 | 3.00 | 2.95 | 2.90 | |

| Cold Crushing Strength, MPa | ≥ | 60 | 60 | 60 | 60 | |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1700 | 1700 | 1650 | 1560 | |

| Permanent Linear Change, % | 1650℃*2h -0.2~0 | 1650℃*2h -0.3~0 | 1600℃*2h -0.5~0 |

|||

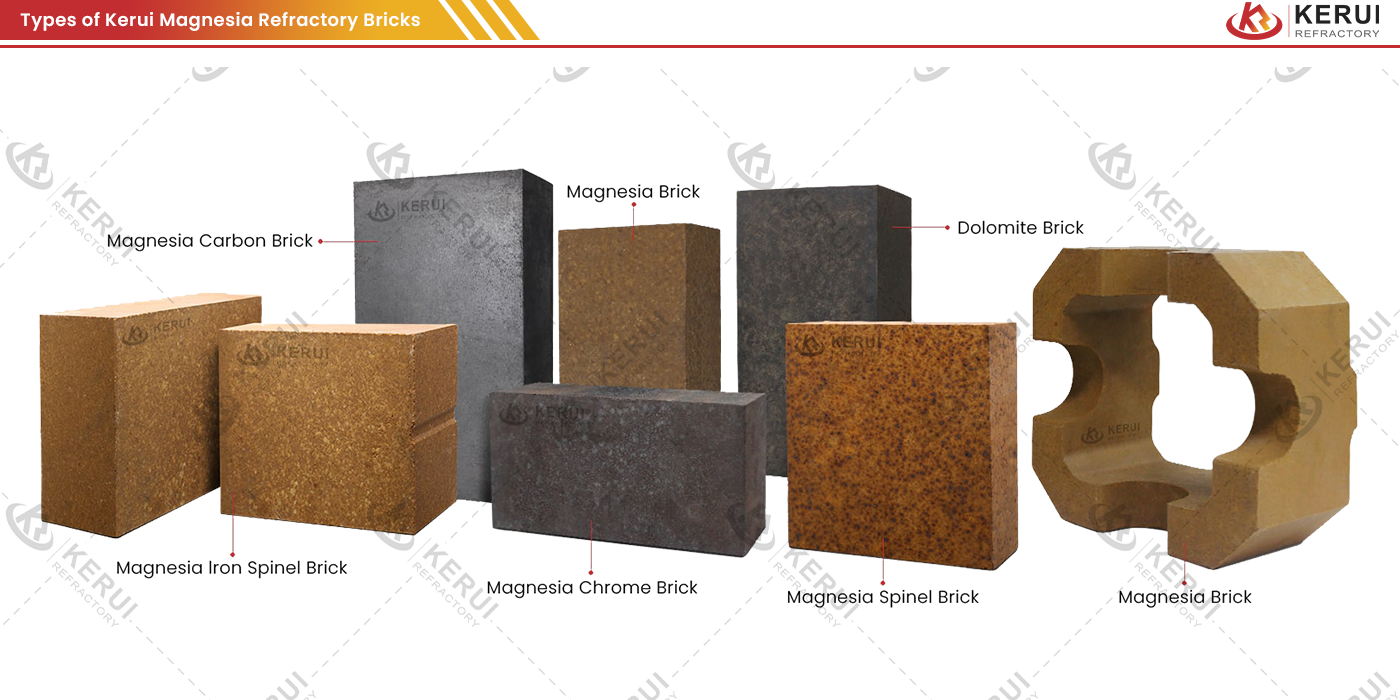

Types of Magnesia Refractory Bricks

Magnesite bricks are mainly made from natural magnesite materials, and their magnesium oxide content exceeds 89%. Because of this high purity, they exhibit excellent thermal stability. Moreover, the melting point of magnesite is as high as 2800ºC, which means that these bricks are highly refractory and suitable for use in extremely high-temperature environments. Depending on the production process as well as the specific material properties, magnesia bricks can be divided into the following types:

| Types | Features | |

| Ordinary Magnesia Brick | Burned Magnesite Refractory Bricks; Chemically Bonded Magnesium Bricks; High Purity Magnesia Brick; Fused Magnesia Brick. |

Strong resistance to alkaline slag erosion; High thermal conductivity; High refractoriness; The higher the MgO content and the firing temperature, the better the gas erosion resistance and high-temp resistance. |

| Magnesium Aluminum Brick | Magnesia Alumina Spinel Brick; Fused And Bonded Magnesia Bricks; Magnesia-Silica Bricks; Forsterite Bricks. |

High temperature resistance; High strength; Good thermal shock stability; Strong corrosion resistance; Good volume stability; Environmentally friendly and chrome-free; Good peeling resistance. |

| Magnesia Carbon Brick | / | Good high temperature resistance; Strong slag resistance; Good thermal shock resistance; Low high temperature creep. |

| Magnesia Chrome Brick | Direct Bonded Magnesia Chrome Bricks; Semi-Rebonded Magnesia Chrome Bricks; Electro-Fused Rebonded Magnesia Chrome Bricks. |

High refractoriness; High high temperature strength; Strong resistance to alkaline slag erosion; Excellent thermal stability; Certain adaptability to acidic slag. |

Video of Kerui Magnesia Refractory Bricks

This video fully presents the entire process of magnesia brick production, including raw material processing, intelligent production line operation, standardized quality inspection, professional packaging, and efficient logistics delivery. Therefore, Kerui sincerely invites partners to visit our company for an on-site inspection, so that you can explore the modern production base and engage in in-depth exchanges on cooperation matters. To ensure a smooth visit, please register in advance for the factory visit time.

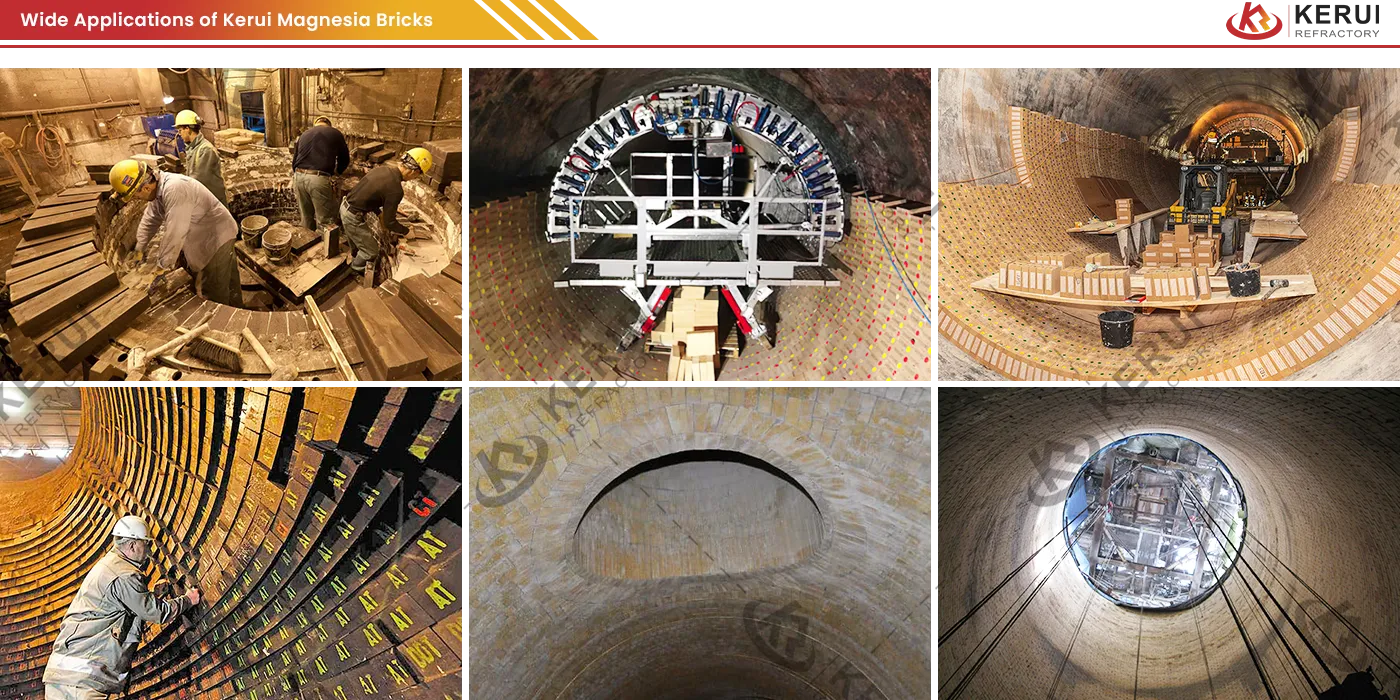

Industries Magnesite Bricks Applied For

Ironmaking furnace;

Mixer furnace;

Converter;

Ladle;

Electric arc furnace.

Lime kiln;

Calcination kiln;

Rotary kiln for mud recycling;

Heating furnace.

Copper, lead, nickel, zinc, tin smelting furnaces;

Non-ferrous metal kilns.

Heat exchanger;

Glass kiln;

Glass tank grid.

Kerui Magnesia Refractory Bricks Shipped to the World

KERUI magnesia bricks have won the trust of partners in more than 50 countries around the world, including internationally renowned companies such as RUSAL, CHALCO, ALBA, POSCO, and PSM. Not only do these industry leaders highly evaluate the product quality, but they also establish long-term and stable strategic partnerships with us. Therefore, we will continue to pursue mutual benefit and win-win results through in-depth global cooperation.

Competitive Factory Magnesite Bricks Price

If you want to know the detailed price of magnesia bricks, please send us your requirements, because the price depends on quantity, size, and composition. Moreover, as a magnesia brick manufacturer, Kerui Refractory provides very competitive prices as well as services. In order to determine your detailed needs more accurately, please send us the following information:

- Application scenarios, such as cement kiln rotary kiln.

- Kiln size and operating temperature, such as regular size.

- Types and requirements of refractory fire bricks, such as magnesia chrome bricks.

- Project schedule, such as starting in the third quarter.

- Construction requirements, such as the need for on-site technical guidance.

Choose Kerui Refractory as Magnesia Brick Manufacturer

Kerui Refractory has over 20 years of experience in the magnesia brick industry, and many customers choose us not only because of our strong company capabilities but also because of our comprehensive services.

With over 30 patented technologies, certificates, and company honors, we not only ensure the quality and quantity of magnesia brick production but also continuously upgrade our processes.

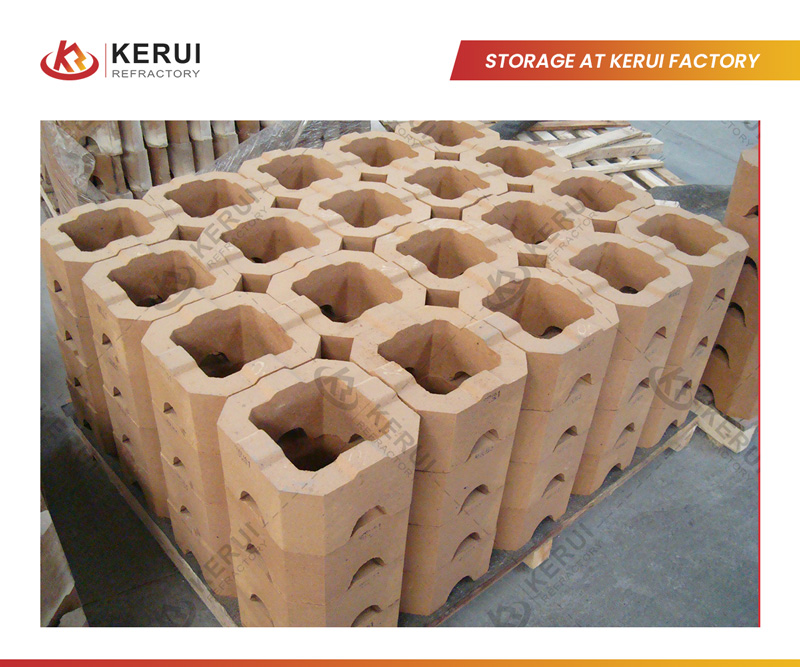

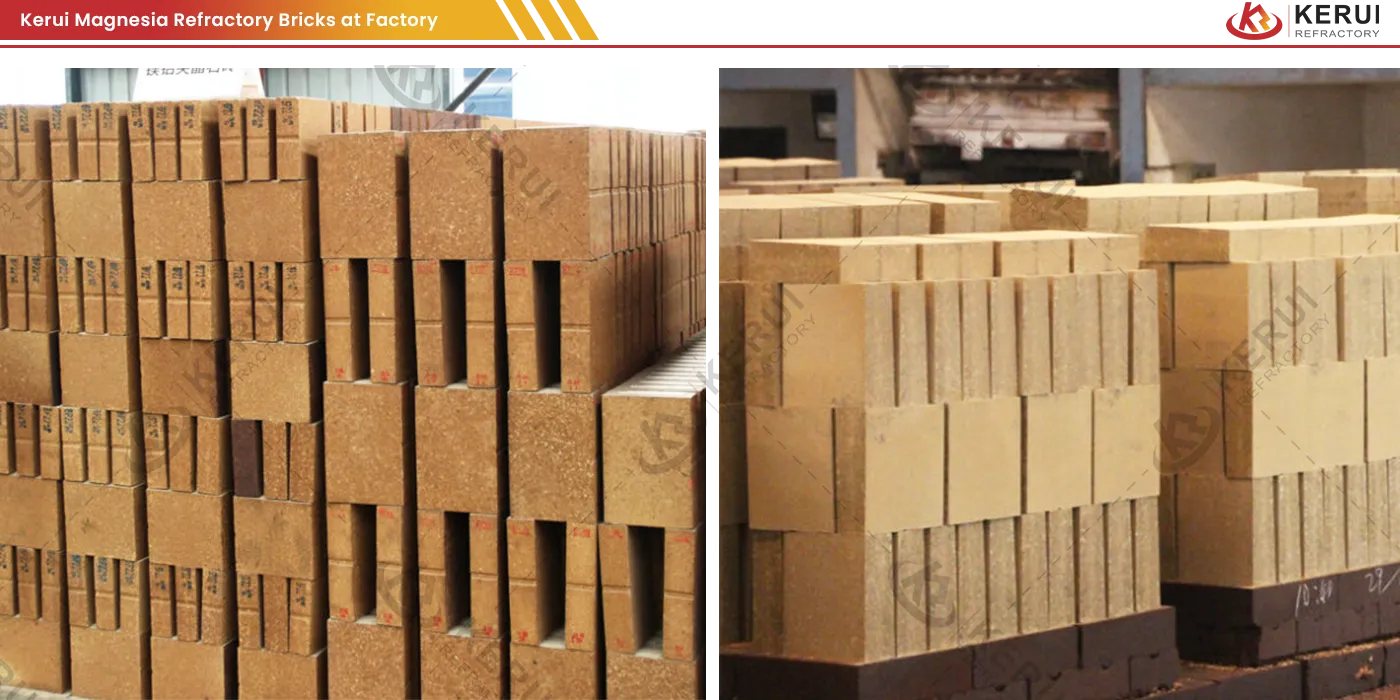

Kerui has 20 pressure equipment units as well as 2 sets of 168-meter tunnel kilns. These together guarantee the production volume.

Our team of over 100 factory professionals not only conducts rigorous inspections but also handles the packaging and shipping of bricks.

![]()

We offer customized magnesia brick services.

Based on the requirements of the kiln, we can provide customers with design drawings and recommendations for refractory materials.

Our professional construction team is available on-site to assist customers with the construction and trial operation of magnesia bricks.

Contact Kerui Refractory to Get Your Magnesia Bricks Now!

Kerui magnesia refractory bricks boast high quality and large output because of our automated and precise production line. We also provide detailed solutions tailored to meet customer requirements. Join us to experience the quality and reliability of Kerui magnesia bricks and services, and witness the difference in performance and durability. See the company information on Linkedin.