In high-temperature applications requiring efficient thermal insulation, the ceramic fibre board 50mm stands out as an ideal solution for industrial users. Kerui Refractory provides high-quality ceramic fiber boards with uniform density and precise thickness control. With strict quality standards and reliable technical support, Kerui helps customers achieve optimal insulation solutions for demanding industrial environments.

- Classification Temperature: 1100/1260/1260/1360/1430°C;

- Al2O3:39-55%;

- Bulk Density: 260-320g/cm³;

- Heat Conductivity Coefficient: 0.09-0.22W/(m·k);

- Permanent Liner Change: ≤4.0%;

- Length: 600-1200m (customizable);

- Width: 400/ 500/ 600/ 1000/ 1200mm (customizable);

- Thickness: 50mm (customizable);

- Shipment: 7-15 working days;

Technical Parameters of Ceramic Fibre Board 50mm

Kerui Refractory is a globally recognized supplier of high-temperature industrial materials. The company specializes in developing and producing high-performance refractory products. The 50mm ceramic fiber board is a key part of Kerui’s product line. It is manufactured using advanced vacuum forming technology, ensuring consistent quality and reliable performance.

| Item | Ordinary Type | Standard Type | High Purity Type | High Alumina Type | Zirconium Containing Type |

|---|---|---|---|---|---|

| Classification Temperature, ℃ | 1100 | 1260 | 1260 | 1360 | 1430 |

| Working Temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Bulk & Density, kg/m³ | 260-320 | ||||

| Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1000℃) | -3 (1250℃) | -3 (1350℃) |

| Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃), 0.176 (800℃), 0.22 (1000℃) | ||||

| Strength of Extension, Mpa | 0.5 | ||||

| Al2O3, % | 44 | 46 | 46~49 | 52~55 | 39~40 |

| Al2O3+SiO2, % | 96 | 97 | 99 | 99 | - |

| Al2O3+SiO2+ZrO2, % | - | - | - | - | 99 |

| ZrO2, % | - | - | - | - | 15~17 |

| Fe2O3, % | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

| Size, mm | Length, Width Regular Size, Thickness 3-100mm, Customized Size | ||||

Why Choose Ceramic Fibre Board 50mm for Insulation

- Low thermal conductivity: The 50mm ceramic fiber board provides excellent heat insulation, effectively reducing heat transfer in high-temperature environments and maintaining stable internal temperatures.

- Low heat capacity: Its low heat capacity allows rapid response to heating and cooling cycles, making it ideal for applications requiring frequent temperature adjustments.

- High-temperature resistance: With a maximum service temperature of 1260°C, it is suitable for various demanding industrial environments.

- Thermal shock resistance: Thanks to its lightweight and flexible structure, the board withstands rapid temperature changes without cracking, which is critical in heat treatment and foundry industries.

- Lightweight: Compared to traditional refractory materials, Kerui’s ceramic fiber board is easier to handle and install, reducing structural load.

Application Areas of Ceramic Fibre Board 50mm

- Kilns & Furnaces

- Heat Treatment Equipment

- Foundry Industry

- Boilers & Pipelines

- Other High-Temperature Applications

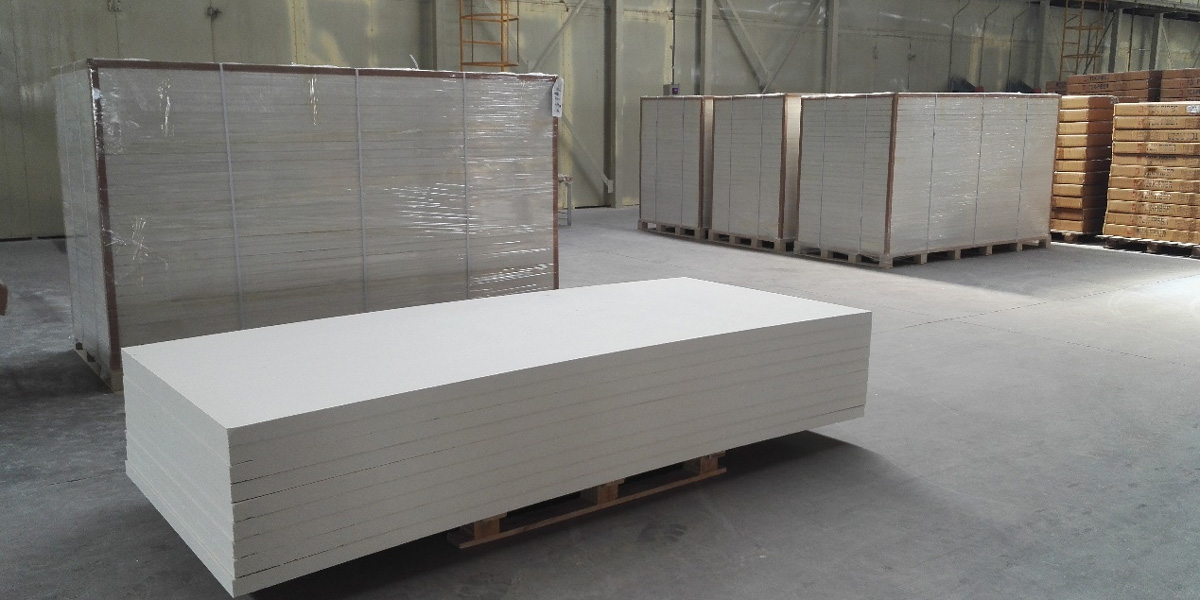

Efficient Shipping Process Ensures Smooth Project Execution

Kerui Refractory is committed to providing customers with efficient and reliable shipping services. Our standardized shipping process includes the following steps:

- Order Confirmation

Kerui’s customer service team promptly verifies order details upon submission and coordinates production/shipping arrangements. - Production Scheduling

The production team executes manufacturing according to order requirements with strict timeline management. - Quality Inspection

Every batch undergoes rigorous quality testing to guarantee compliance with technical specifications. - Secure Packaging

Approved aluminum silicate fiber products receive protective packaging to prevent transit damage. - Dependable Delivery

Shipments are dispatched via trusted logistics partners to ensure on-time arrival.

Kerui’s Customers Over the World

Kerui Refractory serves customers worldwide, including industry leaders in steel, aluminum, glass, cement, and other key sectors. Our products have earned widespread recognition for their consistent quality and dependable performance.

Choosing Kerui Refractory for Your Insulation Solutions

Kerui Refractory has established comprehensive strengths in high-temperature industrial materials through concrete business practices:

- Technology Leadership

Maintains dedicated R&D centers with 15+ patented refractory technologies;

Annual introduction of 3-5 new material formulations to address specific industry challenges;

Developed low-thermal-conductivity insulation boards for aluminum smelters for reducing energy consumption by 12%. - Quality Excellence

ISO 9001-certified manufacturing facilities with batch-level quality tracking;

Third-party lab testing reports available for all product lines;

Consistently rated “A” supplier by global steel mills for 5 consecutive years. - Customer Solutions

24/7 technical hotline with an average 4-hour response time;

On-site service teams covering 30+ countries;

98% customer satisfaction rate in post-installation surveys. View more views on LinkedIn.