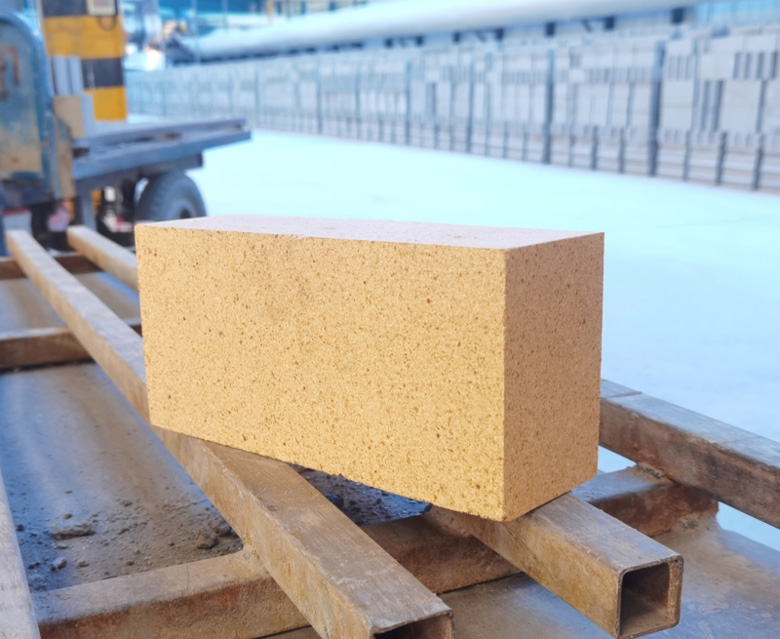

Fire clay brick is made of calcined clay grog. It has a high alumina content of up to 42%. Kerui Refractory can produce standard and special fire clay bricks according to customer requirements. 1000+ partners have chosen to cooperate with us, including RUSAL, CHALCO, ALBA, POSCO, PSM, etc.

- Al2O3: ≥30-48%;

- Bulk Density: 1.9-2.22g/cm³;

- Refractoriness Under Load: 1250-1420ºC;

- Cold Crushing Strength: 30-45MPa;

- Size: 230*114*65mm (standard)/And other sizes;

Parameters of Kerui Fire Clay Bricks – SK Series

Kerui provides a series of sk fireclay bricks, including SK30, SK32, SK34, and SK35. Please see the following parameters. If you need other types, please send us the specification.

| Item/Grade | SK-30 | SK-32 | SK-34 | SK-35 | |

|---|---|---|---|---|---|

| Al2O3, % | ≥ | 30 | 35 | 38 | 45 |

| Fe2O3, % | ≤ | 2.5 | 2.5 | 2 | 2 |

| Refractoriness (SK) | ≥ | 30 | 32 | 34 | 35 |

| Refractoriness underload, 0.2MPa, °C | ≥ | 1250 | 1300 | 1360 | 1420 |

| Apparent Porosity, % | ≤ | 22-26 | 20-24 | 20-22 | 18-20 |

| Bulk Density, g/cm³ | ≥ | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 |

| Cold Crushing Strength, MPa | ≥ | 40 | 45 | 30 | 40 |

Introduction of Fire Clay Brick for Sale

Clay fire bricks are made of calcined clay and binder. They are a type of siliceous alumina brick. Their refractoriness is between 1580-1770 degrees Celsius. With the change of composition, the refractoriness fluctuates. In addition, because clay bricks contain alumina, they have a certain anti-erosion effect on acidic slags. They are generally used in acidic slag kilns.

Advantages of Fire Clay Refractory Brick

- High refractoriness: Its refractoriness is as high as 1770 degrees Celsius.

- High softening temperature: The softening temperature is generally between 1300-1400 degrees Celsius.

- Strong resistance to thermal shock: It can resist sudden changes in temperature. It has a stable structure in high temperature.

- Resistant to acidic chemical erosion: Clay firebricks can resist the erosion of acidic slag and acidic gases.

- Affordable price: Clay firebricks have a wide range of raw material sources. Therefore, its price is more acceptable to customers.

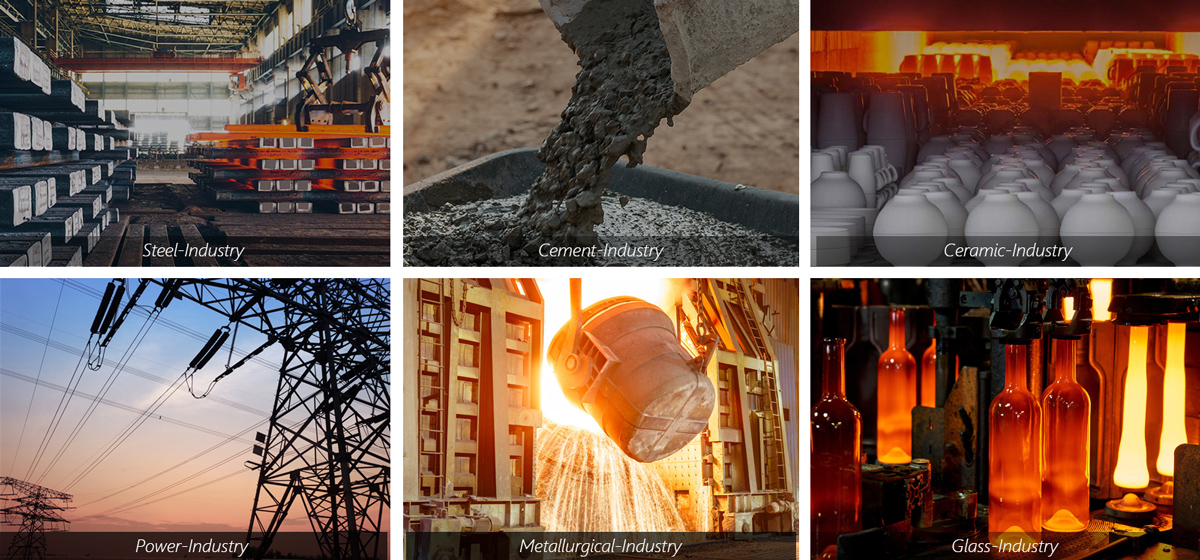

Applications of Fireclay Brick

- Metallurgical Industry: Industries mainly use clay firebricks in ladles, hot blast stoves, regenerators, tap holes, steelmaking furnaces, electric furnaces, blast furnaces, kilns, chimneys, and similar equipment. Operators generally place them in the hearth, walls, waist, belly, and other parts of the furnace. The types of refractory bricks used include clay universal arch bricks, such as sleeve bricks, clay lattice bricks, acid-resistant bricks, etc.

- Building Materials Industry: In the building materials industry, factories mainly use clay firebricks in their kilns—such as kaolin tunnel kilns, ceramsite rotary kilns, lime vertical kilns, glass melting kilns, and glass regenerators. They typically place the bricks in the hearth, walls, preheating zone, transition zone, secondary working layer, and other non-critical areas. The types of bricks used are more extensive.

- Coke Making Industry: “Operators often use clay fired bricks in reactors, regenerators, incinerators, and chemical furnaces. They typically install these bricks in the lining, door, flue, hearth, wall, and top of the furnace.

- Carbon and Graphite Industry: Clay fire blocks are widely used in carbon baking furnaces and graphitization furnaces. This industry usually uses low-creep clay bricks and dense clay bricks.

Cooperate with the Leading Manufacturer – Kerui

As a manufacturer, Kerui has a factory with an annual output of 250,000 tons. We have complete production and inspection processes. And our products comply with national standards. We have multiple international certificates and patents. We very much welcome partners to visit our factory. See some information on Facebook.