Refractory mortar is primarily used for laying refractory bricks and repairing refractory furnaces. High-quality Kerui mortar can maintain stable performance in high-temperature environments. We can provide mortar with different specifications according to customer requirements. Our professional technicians will provide you with suitable refractory solutions.

- Al2O3: 40-78%;

- Fe2O3: 0.7-1.2%;

- Refractoriness Underload: 1320-1600ºC;

- Classification Temperature: 1300-1600ºC;

- Package: 25kg bag/1 ton bag/25kg barrel;

Types of Refractory Motar

Kerui refractory mortars can be classified into high-alumina refractory mortars, silica refractory mortars, and magnesia refractory mortars. The difference in chemical composition affects the refractoriness and chemical corrosion resistance of the mortar.

Parameters of Kerui Fire Brick Motar

| Item/Grade | KR-1300 | KR-1400 | KR-1500 | KR-1600 | |

|---|---|---|---|---|---|

| Classification Temperature/℃ | 1300 | 1400 | 1500 | 1600 | |

| Chemical Composition/% | ω (Al2O3)/% | 40 | 53 | 60 | 78 |

| ω (Fe2O3)/% | 1.2 | 1 | 0.9 | 0.7 | |

| Refractoriness Underload/℃ | 1320 | 1410 | 1550 | 1600 | |

Introduction of Kerui Refractory Mortar

Refractory motar is one of unshaped refractories made by mixing special refractory cement and refractory aggregates.

- Components: Refractory mortar mainly consists of binders, aggregates, additives, and fillers, such as refractory cement, quartz, corundum, and high-alumina bauxite.

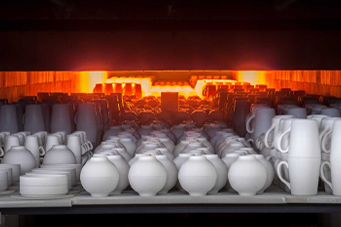

- Factory Production: The Kerui factory is equipped with intelligent machinery and a strict quality inspection system. The refractory mortar produced has high quality.

- Factory Price: We offer affordable factory prices.

- Customization Services: If customers require unconventional refractory mortar, please let us know your needs. We will customize suitable refractory materials based on your usage.

Advantages of Refractory Mortar Mix

- High refractoriness: The refractoriness underload of refractory mortar ranges from 1320 to 1600 degrees Celsius. It maintains structural stability at high temperatures.

- Strong thermal shock resistance: When subjected to thermal shock in kilns or application equipment, it can maintain a stable structure and resist spalling.

- Abrasion resistance: In equipment with high mechanical strength, it has high abrasion and compressive strength.

- Strong corrosion resistance: Refractory mortar is not affected by chemical corrosion.

- Good workability: It is flexible and easy to apply. It also has a fast setting time.

Applications of High Temp Mortar Mix

- Masonry Lining: High-temp mortar is an important binder for masonry lining of high-temperature industrial equipment. Its application is also for sealing joints in kilns.

- Lining Repair: Its uses are to repair cracks, spalling, and other signs of damage to the lining of high-temperature equipment.

- Refractory Material: It can be used as an aggregate to make refractory concrete.

Kerui Refractory Mortar Shipped to the Global World

- 500+ Customers: Due to our commitment to high-quality service and exceptional products, over 500 customers have chosen to partner with us. These customers span a diverse range of high-temperature industries, including cement and steel manufacturing. their demands for reliable and efficient refractory solutions are critical.

- Solutions: The common goal shared between us and our customers is the development of suitable refractory material solutions that meet their specific operational needs. We understand that each industry has unique challenges, and we strive to provide tailored solutions that enhance performance, safety, and efficiency in high-temperature environments.

- High Satisfaction: With more than 20 years of industry experience, we have a deep understanding of the complexities and requirements of various high-temperature applications. Our extensive background allows us to not only meet but exceed our customers’ expectations. This results in high satisfaction among our customers. If you wanna see more news, see Kerui Facebook