Silica refractory brick is an acidic refractory material. The SiO2 content reaches above 94%. This refractory brick has good high-temperature resistance. This kind of bricks are used in kilns. Kerui Refractory has more than 20-year experience of manufacturing and exporting. We offers a wide range of refractory bricks to partners.

- SiO2: ≥94-96%;

- Bulk Density: 2.34-2.35g/cm³;

- Refractoriness Under Load: 1650-1670ºC;

- Refractory Degree: 1690~1730ºC;

- Cold Crushing Strength: 25-35 MPa;

- Standard size: 230*114*65mm and other sizes.

- Silica Bricks Price: The greater the quantity is, the greater the discount is.

Specification Data of Kerui Silica Bricks

Kerui Refractory mainly provides the following types of refractory brick to customers.

| Item | GZ-94 | GZ-96 | |

|---|---|---|---|

| SiO2, % | ≥ | 94 | 96 |

| Fe2O3, % | ≤ | 1.4 | 1.0 |

| Apparent Porosity, % | ≤ | 22 | 22 |

| Bulk Density, g/cm³ | ≤ | 2.35 | 2.34 |

| Cold Crushing Strength, MPa | ≥ | 30 | 40 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1650 | 1670 |

High-quality Components of Silica Refractory Bricks

Kerui silica refractory brick is a refractory brick with high-quality silicon dioxide as the main component. This brick is made from natural silica stone as raw material. It adds a suitable amount of mineralizer and is fired at 1350-1430ºC.

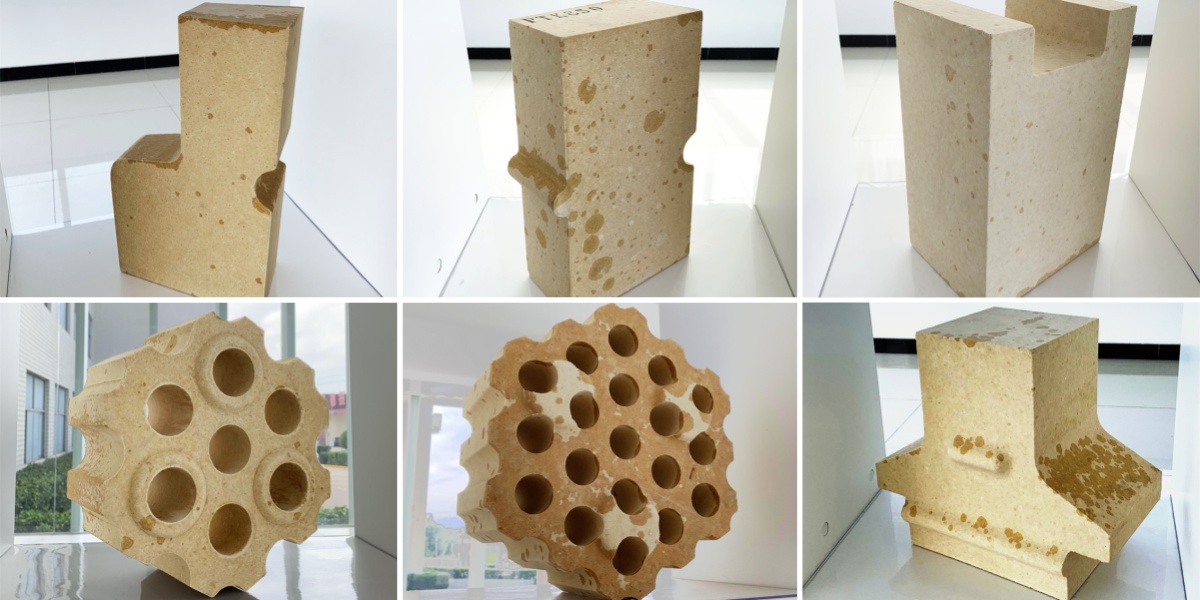

After firing, the mineral composition of the silicon bricks changes. It mainly consists of cristobalite, tridymite, residual quartz, diopside, glass phase, and so on. The mineralizer (lime milk) promotes the formation of the scale quartz phase. Therefore, bricks have spots on them.

Other Shapes of Silica Bricks

In addition to standard straight bricks, we also offer bricks in a variety of shapes, including special-shaped bricks, checkered bricks, ax bricks, anchor bricks, composite bricks, universal arc bricks, curved bricks, and so on.

Properties of Silica Bricks

High Temperature Stability

The high load softening temperature of silicon brick reaches 1640-1670ºC. The stability of volume change ensures that it maintains its structural integrity and performance under extreme high-temperature conditions.

Acid Slag Erosion Resistance

The acid resistance and slag erosion resistance of silicon brick protect it from chemical corrosion in environments with acidic or corrosive substances, for example, CaO、FeO、Fe2O3, and other oxides. It is different from mag carbon bricks.

Low Thermal Conductivity

The low thermal conductivity of silicon brick helps maintain consistent temperatures within the structure. The silica refractory brick properties can improve energy efficiency and overall performance while also resisting thermal shock.

High Gas Tightness

The high gas tightness of silicon brick helps maintain the required atmosphere within the structure. It ensures efficient operation and excellent performance of industrial kilns. This is crucial for safety and efficiency in high-temperature and high-pressure kiln environments.

Note: 1. Silicon bricks are not suitable for alkaline working environments. They are easily damaged by oxides containing Al2O3, K2O, and Na2O.

2. They are not suitable for working in environments below 800 degrees Celsius because of poor earthquake resistance. Below 800 degrees Celsius, the furnace needs to be slowly heated and cooled.

Video of Kerui Silica Fire Brick

Applications of Silica Fire Brick

Glass Furnace

A large number of silicon bricks are commonly used in the construction of glass furnace arches, glass melting pots, glass furnace walls, and kiln roofs. Its application in glass furnaces offers the following advantages: strong resistance to acid slag erosion, strong thermal shock resistance, stable volume at high temperatures, and so on.

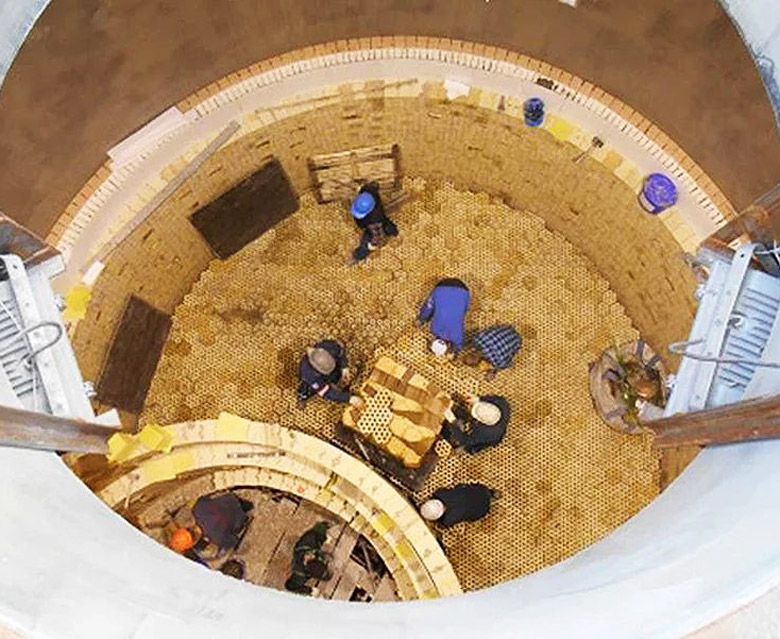

Coke Oven

In coke ovens, silicon bricks are typically used in carbonization chambers, combustion chambers, walls, heat storage chambers, and chutes, among others. Silicon bricks provide certain irreplaceable advantages for continuous production coke ovens, such as high load softening temperature, strong thermal shock resistance, low thermal conductivity, strong resistance to acid slag erosion, and so on.

Hot Blast Stove

Silicon bricks are commonly used in the walls and arches of hot blast stoves. This is because silicon bricks can maintain stable volume at high temperatures in hot blast stoves. They resist the erosion of acidic substances and maintain consistent temperature with the furnace interior. They are an ideal choice for maintaining the integrity of hot blast stove structures.

Acid Steelmaking Converter

A large number of silicon bricks are used in the heat storage chamber and slag chamber of acid steelmaking converters. Due to their excellent acid resistance and high load softening temperature, silicon bricks can maintain stable structure and performance in acid steelmaking converters, helping equipment to operate stably over the long term.

Global Cases of Kerui Silica Firebrick

Due to their reliable quality and comprehensive service, Kerui has sold refractory silica bricks to over 30 countries, including Turkey, Indonesia, Kyrgyzstan, and others. These countries have a large demand for refractory materials. When our comprehensive solutions met these customers’ high temperature needs, they chose to work with us. The global cases are here.

Choose Silica Refractory Brick Manufacturer – Kerui Refractory

Keru Refractory is a manufacturer of silicon bricks and an expert in application solutions. We provide customers with a wide range of services. We can help customers with everything from product selection to project construction and training in a one-stop service.

Silicon Brick Product Services

- Kerui has a strong silicon brick production factory. We offer competitive silica brick prices.

- Customers can enjoy customized fused silica refractory brick services, including shapes, sizes, and chemical compositions.

- The silicon bricks produced by Kerui Refractory are of high quality, undergoing multiple tests such as high-temperature firing, softening and creeping tests, and flexural strength tests.

- With a strong production capacity, we can deliver silicon bricks to customers in bulk on time and of high quality.

Silicon Brick Solution Services

- We provide suitable silicon bricks and comprehensive solutions for other products based on customers’ application scenarios.

- Depending on the kiln situation of the customer, Kerui Refractory provides design drawings and other diagrams.

- Kerui Refractory’s professional shipping team offers the best container loading plans and transportation routes based on the quantity and size of silicon bricks and other products.

- An experienced construction team assists customers on-site with construction and debugging to ensure accuracy.

Cooperate with Kerui Refractory to Get Your Silica Brick Solutions

Kerui Refractory focuses on providing high-quality silicon bricks and comprehensive kiln solutions. We have a professional team that can customize refractory material solutions according to customer needs. This service ensures compliance with various industrial applications. If you have any interest in our products or questions, we encourage you to contact us immediately. And we will be happy to assist you. View more videos to see our products.