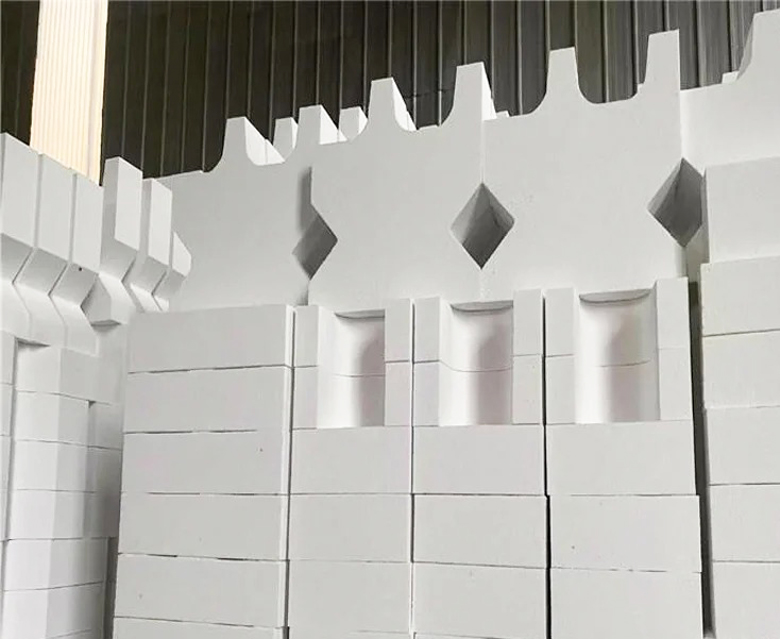

Corundum mullite brick is composed of high-purity corundum and mullite. It belongs to refractory brick that can used at 1700℃. It has stable chemical properties that will not react with chemical gases. Kerui has exported this brick to 2000+ partners all over the world.

- Al2O3: ≥70-90%;

- SiO2: 3.0/9.0/18%;

- Bulk Density: 2.55-2.90g/cm³;

- Permanent Linear Change: ±0.2%(1600×3h);

- Size: 230*114*65mm (standard)/And other sizes;

- Delivery: 15-30 working days;

Technological Specification of Corundum Mullite Brick

| Item/Index | Mullite Bricks | Resintering Fused Mullite Bricks | Mullite-Corundum Bricks | Corundum-Mullite Bricks |

|---|---|---|---|---|

| Al2O3 | ≥70% | ≥75% | ≥80% | ≥90% |

| SiO2 | ≤25% | ≤23% | ≤18% | ≤8% |

| Fe2O3 | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.3% |

| Apparent Porosity | ≤17% | ≤14% | ≤19% | ≤18% |

| Bulk Density | ≥2.55g/cm | ≥2.65g/cm | ≥2.70g/cm | ≥2.90g/cm |

| Cold Crushing Strength | ≥90MPa | ≥100MPa | ≥80MPa | ≥100MPa |

| Initial Refractoriness Under Load | ≥1630℃ | ≥1700℃ | ≥1650℃ | ≥1700℃ |

Benefits of Corundum Mullite Bricks

High Refractoriness Under Load

The refractoriness under load of corundum mullite brick is 1700℃. The high refractoriness helps refractory brick for sale withstand high-temperature industrial equipment. So corundum mullite brick can directly contact the flame.

Good Thermal Shock Resistance

Corundum mullite brick can undertake 30 times extreme temperature changes in the thermal shock test. It will not peel off in extreme temperature changes. This can prevent the debris from impacting production.

Chemical Resistance

Stable chemical property contributes to resisting chemical gases and slags. The gas ovens need to use chemically stable refractory bricks to construct so as to sustain the volume stability of gas ovens.

Applications of Corundum Mullite Bricks

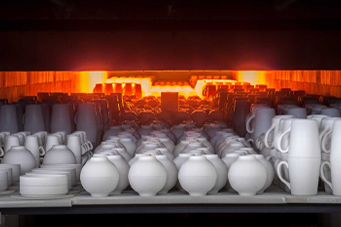

Corundum mullite bricks are mainly used in the petrochemical industry, cement and lime industry, including large and medium-sized synthetic ammonia gasifiers and magnetic material gas furnaces. It can also used for the linings of metallurgy high-temperature equipment including the hearth of decomposing furnaces, blast furnaces, hot blast stoves, and so on.

Strict Production Process

In the production process, the bricks that use corundum as a coarse aggregate have better erosion resistance. Conversely, the bricks that use mullite as a coarse aggregate have better thermal shock resistance.

Contact Kerui Refractory

Kerui will strictly control the ratio of raw materials. We have automatic batching equipment to ensure an accurate ratio. Every batch of Kerui products will randomly inspect some samples before leaving the factory. This can guarantee that the high-quality corundum mullite bricks are delivered to every customer. If you need any technology support, we have a professional technological team to solve the problems. Besides, if you need to construct high-temperature equipment, we can provide turnkey service for you. View more pictures at Kerui Pinterest.