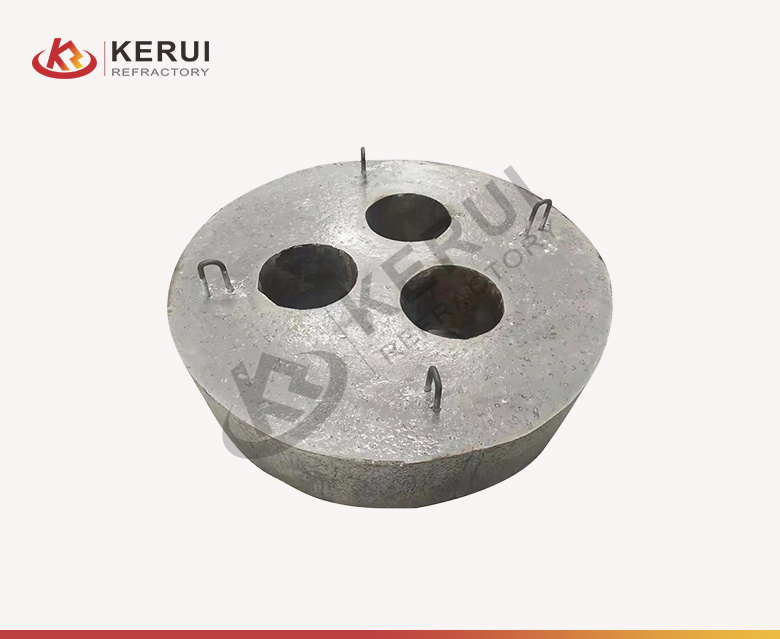

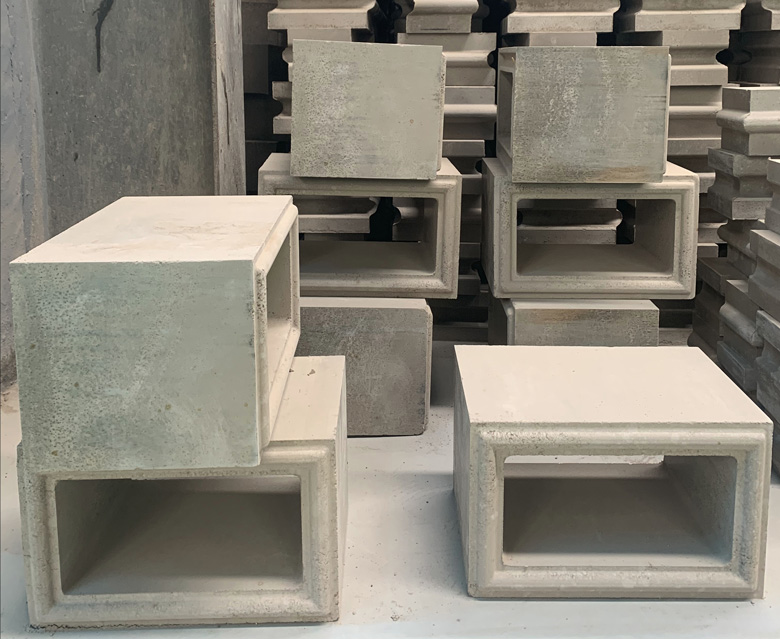

Refractory precast shapes are refractory materials made by pouring casting materials into specific shapes. Kerui Refractory has over 20 years of production experience. We provide partners with precast in various materials, sizes, shapes, and finishes. We can offer customers any required refractory lining. Over 1000 customers have chosen to work with us. These customers come from Russia, Indonesia, and other countries.

- Al2O3 + SiC: ≥85-92%;

- Bulk Density: 2.85-2.9;

- Crushing Strength: ≥80-120Mpa;

- Cold Bending Strength: 3-9Mpa;

- Innovative Molding Technology;

- Strict Processing Control;

- Support For High-Temperature Firing;

- Precise Size Control;

- From Simple to Complex Shapes;

Specifications of Kerui Refractory Precast

| Item | Performance | ||

|---|---|---|---|

| Types | GQ-92 | GQ-85 | |

| (Al2O3 + SiC)/% ≥ | 92 | 85 | |

| CaO/% ≤ | 4 | 4 | |

| Crushing Strength/MPa ≥ | 110℃*24h After drying | 80 | 60 |

| 1100℃*3h After reburning | 100 | 70 | |

| 1500℃*3h After reburning | 120 | 100 | |

| Cold Bending Strength/Mpa | 110℃*24h After drying | 8 | 6 |

| 1100℃*3h After reburning | 9 | 7 | |

| 1500℃*3h After reburning | 10 | 9 | |

| Heating Linear Change/% | 1100℃*3h After reburning | ±0.5 | ±0.5 |

| 1500℃*3h After reburning | ±0.5 | ±0.5 | |

| Bulk Density | 110℃*24h After drying | 2.9 | 2.85 |

This parameter table mainly displays precast refractory shapes made from silicon carbide casting material. We support precasts made from various refractory materials, such as high alumina casting material.

High-quality and Precise Production Refractory Precast

Kerui refractory precast block provides a solution for the high-temperature industry that does not require on-site casting during construction. We offer high-quality precast refractory.

- Raw Materials: Kerui Refractory uses high-quality casting materials to produce refractory precast blocks, including corundum silicon castable, high alumina silicon carbide castable, high alumina castable, low cement castable, steel fiber wear-resistant castable, anti-seepage castable, and so on. These castables can all be made into high-performance refractory precast.

- Production Process: We have high-quality and precise production equipment. We support custom-made prefabricated blocks for specific areas. Carefully designed molds ensure that the casting dimensions and shapes meet the needs of our partners.

- High-Temperature Firing: The refractory precast blocks we produce support high-temperature firing. The firing temperature reaches to 1680 degrees Celsius.

- Suitable parts: These refractory precasts can be used in areas such as abrasion, erosion, thermal shock, metal penetration, and so on.

- Functions: Internal support, external connections, and so on.

Advantages of Kerui Refractory Precast Blocks

- Meet any size;

- Meet any shape;

- Including simple and complex shapes;

- Excellent non-wetting properties;

- Easy to clean and maintain refractory materials;

- Easy to install, quick installation;

- Reduce downtime, reduce drying time;

- More durable than cast-in-place components;

- High temperature resistance;

- Wear resistance;

- Chemical resistance;

- High mechanical strength.

Applications of Refractory Pre Cast Blocks

Precast shapes are widely used in the steel smelting industry, aluminum industry, copper industry, cement industry, chemical industry, heat treatment industry, foundry industry, and so on.

They are mainly used in the following areas:

Burner blocks, trough linings, ladle linings, induction furnaces, boilers, heat treatment furnaces, refining furnaces, ladles, tundishes, electric arc furnaces, converters, blast furnaces, trough cross-sections, furnace hearth plates, baffles, coolers, cyclone separators, nozzles, Iron ore powder roasting shaft furnace, hot air stove, heating furnace, and others.

Global Cases of Refractory Precast

Over 1000+ partners have chosen Kerui Refractory precast and other refractory products. These partners include RUSAL, CHALCO, ALBA, POSCO, PSM, etc. Many of these partners have repeatedly chosen to work with us.

Choose Kerui Refractory as a Refractory Precast Manufacturer

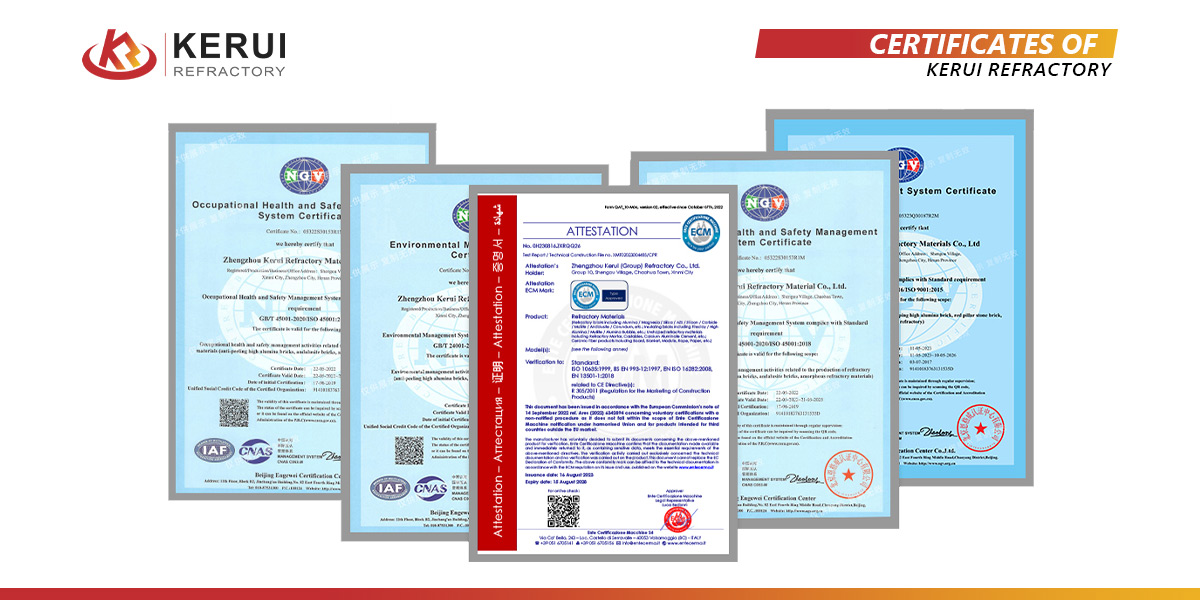

- Each batch of refractory precast undergoes quality testing;

- International certificates and patent certificates;

- Support for making refractory precast according to drawings;

- Strict and precise control of the production process;

- Fast delivery cycles, and professional installation guidance.

Contact Kerui to Get Your Ideal Refractory Precast

The production of refractory precast shapes needs to meet the requirements of our partners. Kerui Refractory has professional knowledge of refractory materials, and over 20 years of experience in manufacturing refractory shapes, and solutions for the high-temperature industry. We are a leading manufacturer in the refractory materials industry. We always provide refractory precasts that meet various types of high-temperature requirements based on the specific needs of our partners. Follow our Pinterest to see more products.