Magnesia chrome brick is mainly made of magnesite and chromite as the main raw materials. They are alkaline refractory materials. Due to the differences in composition and manufacturing processes, the performance of bricks also varies. Kerui Refractory can recommend the appropriate type of magnesia chrome brick and design solutions based on the customer’s kiln situation.

- MgO: ≥45-65%;

- Cr2O3: ≥8-16%;

- Refractoriness Underload: 1530-1650ºC;

- Cold Crushing Strength: 25-35MPa;

- Size: 230*114*65mm (standard)/And other sizes;;

Specifications of Magnesite Chrome Bricks

| Item/Grade | MGe-16A | MGe-16B | MGe-12A | MGe-12B | MGe-8A | MGe-8B | |

|---|---|---|---|---|---|---|---|

| MgO, % | ≥ | 50 | 45 | 60 | 55 | 65 | 60 |

| Cr2O3, % | ≥ | 16 | 16 | 12 | 12 | 8 | 8 |

| Apparent Porosity, % | ≤ | 19 | 22 | 19 | 21 | 19 | 21 |

| Cold Crushing Strength, MPa | ≥ | 35 | 25 | 35 | 30 | 35 | 30 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1650 | 1550 | 1650 | 1550 | 1650 | 1530 |

Kerui Refractory offers four types of magnesia chrome bricks, including ordinary sintered magnesia carbon bricks, directly combined magnesia chrome bricks, fused magnesia chrome bricks, and unfired magnesia chrome bricks. The above parameters are for ordinary sintered magnesia chrome bricks. If you need parameters for other types, please contact us.

- Ordinary sintered magnesia chrome bricks: MGe8/MGe12/MGe16;

- Directly combined magnesia chrome bricks: SRMGe16/SRMGe18/SRMGe20/SRMGe22/SRMGe26;

- Semi-rebonded magnesia chrome brick

- Fused magnesia chrome bricks: RMGe12/RMG14;

- Unfired magnesia chrome bricks: DMGe8/DMGe12/DMGe16.

Introduction to Magnesia Chrome Bricks

Magnesia chrome bricks are mainly produced through sintering. These magnesia refractory bricks can be used in various high-temperature industrial applications. Its main components are magnesium oxide and Cr2O3. The combination of magnesium oxide and Cr2O3 gives this brick several advantages.

- Magnesium oxide serves as the primary component. It has high temperature resistance, corrosion resistance, and good thermal shock stability.

- Cr2O3 serves as the second major component. It can enhance the performance of magnesia chrome bricks, such as refractoriness, corrosion resistance, and thermal shock stability.

Classification of Chrome Magnesite Bricks

Magnesia chrome bricks are mainly classified into sintered magnesia chrome bricks, fused magnesia chrome bricks, and chemically bonded magnesia chrome bricks according to the production process. These high temp refractory bricks have slightly different chrome magnesite bricks properties.

Sintered Magnesia Chrome Bricks

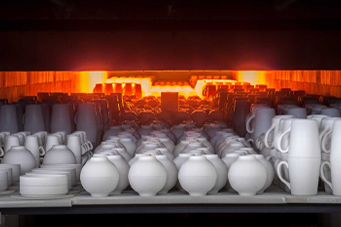

Sintered magnesia chrome bricks are made by high-temperature firing of magnesia sand, chrome ore, and other raw materials. They are mainly divided into ordinary sintered magnesia chrome bricks and directly bonded magnesia chrome bricks. They have high strength and density and are commonly used in industries such as steel smelting and non-ferrous metal smelting.

- Manufacturers make ordinary sintered magnesia chrome bricks by sintering impure magnesia and chromium oxide at high temperatures of 1550 ℃. The sintering temperature is not high.

- Manufacturers make direct bonded magnesia chrome bricks by sintering high-purity magnesia and chromium oxide at temperatures above 1700 ℃. They have better high-temperature resistance and corrosion resistance than ordinary sintered magnesia chrome bricks.

Fused Magnesia Chrome Bricks

Fused magnesia chrome bricks are formed by molding magnesia chrome sand after high-temperature melting in an electric arc furnace. They have high density and low porosity. And they are commonly used in industries such as glass kilns and cement kilns.

Chemically Bonded Magnesia Chrome Bricks

Manufacturers press chemically bonded magnesia chrome bricks from magnesia sand and chrome ore at low temperatures. These bricks offer low cost and easy construction, making them suitable for specific environments.

The Characteristics of Magnesium Chromium Bricks

High Temperature Resistance

Magnesia chrome bricks KR Refractory offers have a refractoriness of up to 1700 degrees Celsius, with a softening temperature range between 1500-1650 degrees Celsius. They exhibit high refractoriness.

Strong Resistance to Alkali Slag Erosion

The magnesia and chromium oxide in magnesia chrome bricks have good corrosion resistance in alkaline environments. They demonstrate excellent chemical stability in alkaline slag. The chromium oxide is helpful in forming a protective layer that enhances corrosion resistance.

Strong Resistance to Spalling

Magnesia chrome bricks have a strong ability to resist spalling or peeling under thermal cycling or mechanical stress. This allows them to maintain structural integrity in high-temperature mechanical conditions.

Environmental Friendliness

Kerui obtains the raw materials for magnesia chrome bricks from natural sources. And their production process is environmentally friendly. Importantly, users can recycle them repeatedly, which helps reduce resource consumption.

Chrome Magnesitea Bricks Are Used for Various Industries

Steel Metallurgy Industry

The steel metallurgy industry uses magnesia chrome refractory bricks to construct blast furnaces, electric furnaces, refining furnaces, oxygen converters, high-temperature tunnel kilns, rotary kilns, heating furnaces, and so on.

Non-ferrous Metal Industry

The non-ferrous metal industry uses them in flash smelting furnaces, smelting furnaces, and other high-temperature equipment. Operators typically apply these bricks in the smelting of copper, aluminum, nickel, zinc, and other metals.

Glass Industry

The glass industry uses magnesia chrome bricks in glass melting furnaces, glass regenerators, and other high-temperature applications. The bricks withstands high temperatures, corrosion, thermal cycling, and other conditions during the glass manufacturing process.

Other Industries

Additionally, other industries such as cement, ceramics, and petrochemicals use magnesia chrome bricks in their processes. They provide reliable and durable refractory solutions for these high-temperature industries for a long-term time.

What Is the Magnesia Chrome Bricks Price?

When planning to construct kilns, magnesia chrome bricks are a crucial component that involves cost and kiln design. Kerui Refractory offers different pricing schemes based on customers’ varying needs. The main factors influencing the price include:

Quantity and Types

Prices of magnesia chrome bricks vary depending on the quantity and types chosen. Customers ordering larger quantities of the same model can benefit from greater discounts.

Manufacturing Process

Manufacturers produce magnesia chrome bricks using various manufacturing processes, each offering different costs and product advantages. Customers can provide detailed requirements for us to tailor the solution accordingly. View about us to see our strength.

Customization Requirements

Kerui Refractory offers customization services for magnesia chrome bricks, including color, shape, size, raw material composition, markings, additives, and so on.

A Manufacturer and Solution Expert for Magnesia Chrome Bricks – Kerui

- As a manufacturer, Kerui Refractory produces up to 250,000 tons annually. And we rank among the top three in the refractory industry in China.

- The company possesses strong factory capabilities and corporate strength. We have over 20 patented technologies, 20+ corporate honors, ISO, and other international certificates.

- The factory operates with full digital control. This system ensures precision in every step to guarantee the high quality of magnesia chrome bricks.

- As solution experts, our international business managers provide personalized consulting services.

- We offer customized magnesia chrome bricks based on customer-provided drawings, including shapes, colors, compositions, and sizes.

- Standard bricks are available for immediate delivery. And we have extensive experience in customizing magnesia chrome bricks with short production cycles and fast delivery times.

- Additionally, we can provide kiln materials solutions and construction technical guidance tailored to the specific needs of our customers.

Kerui Magnesia Chrome Brick is Your Solution!

Kerui produces magnesia chrome bricks through a fully digitalized production system and implements a rigorous quality inspection process to ensure each brick meets high product quality standards. As the original factory, Kerui Refractory offers factory-direct pricing. What’s more, we provide customized refractory material solutions tailored to the specific requirements of your kilns. Drawing on over 20 years of experience and the expertise of 200+ professionals, we help you find the right solutions for your needs. See some videos on YouTube.