High alumina refractory cement with good characteristics is very important for high-temperature industries. Kerui Refractory provides cement with high-quality raw materials and excellent manufacturing process. At the same time, we also provide a series of matching materials and kiln solutions.

- Al2O3: 50-81%;

- SiO2: 0.1-9.0%;

- Flexural Strength: 5.0-10.5Mpa(24h);

- Compressive Strength: ≥25-60Mpa(24h);

- Certification: ISO9001/ISO14001/ISO45001/ISO50001;

- Packaging: 25kg/bag; 1000kg/bag;

- Delivery: 7-15 working days;

Parameters of Kerui High Alumina Cement

| Items | CA50-A600 | CA50-A700 | CA70 | CA80 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Values | Typical | Limit | Typical | Limit | Typical | Limit | Typical | Limit | |

| Chemical Composition | |||||||||

| Al2O3 | % | 50-51 | ≥50 | 50-52 | ≥50 | 68-71 | ≥68 | 78-80 | ≥77 |

| CaO | % | 32-35 | ≥32 | 32-35 | ≥32 | 28-30 | ≤30 | 18-20 | ≤20 |

| SiO2 | % | 7.8-8.3 | ≤9.0 | 7.0-7.5 | ≤8.0 | 0.2-0.7 | ≤1.0 | 0.1-0.4 | ≤0.5 |

| Fe2O3 | % | 1.5-2.5 | ≤3.0 | 1.5-2.5 | ≤3.0 | 0.1-0.5 | ≤0.7 | 0.1-0.4 | ≤0.5 |

| Na2O+K2O | % | - | ≤0.5 | - | ≤0.5 | - | ≤0.4 | - | ≤0.4 |

| Physical Properties | |||||||||

| 325 Mesh Residue | % | - | ≤20 | - | ≤15 | - | ≤8.0 | - | ≤5.0 |

| Blaine Fineness (㎡/kg) | % | - | ≥320 | - | ≥350 | 380-420 | ≥350 | 450-500 | ≥450 |

| Initial Setting Time | min | 50-120 | ≥30 | 50-120 | ≥30 | 180-240 | ≥150 | 150-210 | ≥30 |

| Finish Setting Time | min | 90-180 | ≤360 | 120-210 | ≤360 | 240-300 | ≤360 | 210-270 | ≤300 |

| Flexural Strength (24h) | MPa | - | ≥5.5 | - | ≥6.5 | 9-11 | ≥5.0 | 6-8 | ≥4.0 |

| Flexural Strength (72h) | MPa | - | ≥6.5 | - | ≥7.5 | 11-12 | ≥6.0 | 7-9 | ≥5.0 |

| Compressive Strength (24h) | MPa | 45-55 | ≥40 | 50-60 | ≥50 | 45-55 | ≥30 | 40-50 | ≥25 |

| Compressive Strength (72h) | MPa | 50-60 | ≥50 | 60-65 | ≥60 | 55-65 | ≥40 | 50-60 | ≥30 |

High Alumina Refractory Cement for Sale

High aluminate cement is a water-setting cementitious material.

- Components: This moldable refractory cement is made by high-quality mixing high alumina bauxite, a binder (calcium aluminate, water glass, aluminum sulfate, etc.), and an admixture (water reducer, etc.). Its main components are alumina and silica. Their composition ratio is at least 57.8%.

- Types: Kerui offers CA50, CA70, and CA80 cement. And we support immediate dispatch when this kind of cement in stock.

- Price: Kerui Factory offers factory price because of source factory.

Advantages of Kerui High Aluminous Cement

- Effective resistance to acidic and alkaline slag;

- High compressive strength;

- Good wear resistance;

- High temperature rapid condensation hardening;

- Refractory temperature up to 1750℃;

- Volume stability at high temperatures;

- Any shape and size to be processed;

- The strength improvement and water reducing property of the castable.

Applications of Kerui Aluminous Refractory Cement

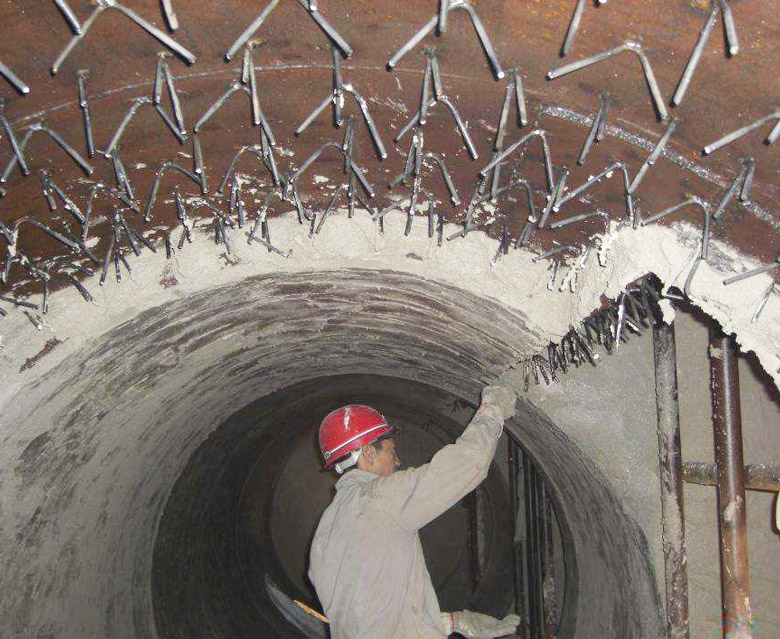

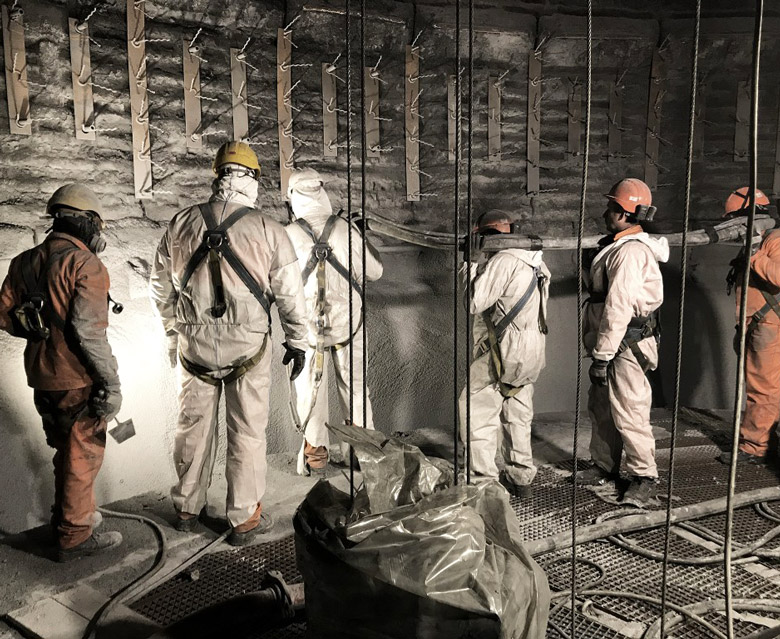

- Masonry

It can be used for masonry of industrial chemical kilns, such as steelmaking furnaces, blast furnaces, electric furnaces, and metallurgical furnaces. - Repair

It can be used to repair various industrial chemical kilns, such as cement kilns, glass kilns, ceramic kilns, and lime kilns. - Manufacturing

It can be used to manufacture refractory products, such as refractory castables, refractory bricks, and refractory coatings.

Global Customers Choose Kerui Aluminous Refractory Cement

Kerui aluminous cement has exported to 50+ countries. They have good common on Kerui cement and services.

- Review 1: “Kerui high-alumina cement has been a game-changer for our construction projects. Its rapid setting time and exceptional strength have significantly improved our efficiency and allowed us to complete projects ahead of schedule.”

- Review 2: “Kerui high-alumina cement has exceeded our expectations in terms of durability and longevity. Even in the harshest conditions, it continues to perform exceptionally well.”

- Review 3: “As a contractor, I appreciate the versatility of Kerui high-alumina cement. Its application is for a wide range of applications, from refractory lining to anchoring and grouting.”

Kerui Refractory is Your Reliable Manufacturer

- Complete industry and product certifications; View the company on Linkedin.

- Large-scale factory production capabilities;

- Strict quality control system;

- Refractory packaging solutions;

- Precise packaging and rapid delivery;

- After-sales technical guidance.