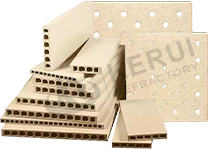

Kiln shelves are a high-temperature product that can directly contact the fired material. It has a maximum working temperature of 1650ºC. Kerui Refractory offers two kinds of kiln furniture, including cordierit-mullite kiln shelves and silicon carbide kiln shelves (OBSIC, SIC, SiSiC/RBSiC, RSiC, NSiC, SSiC). We also offer a variety of hot common sizes and customized products to 100+ global customers.

Kerui Kiln Shelves for Sale

Keri provides the following two types of kiln shelves, including cordierite mullite kiln furniture and silicon carbide kiln furniture. Please choose the appropriate product according to the usage scenario. Please see the specific parameters.

NO.1 Cordierit Mullite Pottery Kiln Shelves (500-1300°C)

| Item | Index |

|---|---|

| Mineralogy | Cordierite-Mullite |

| Al2O3, % | 37 |

| SiO2, % | 50 |

| MgO, % | 8 |

| Bulk Density, g/cm³ | 1.85 |

| Apparent Porosity, % | 28 |

| M.O.R. @ 20°C, Mpa | 15 |

| M.O.R. @1250°C, Mpa | 13 |

| C-16 .T.E.@ 25℃-1000, 10 K | 2.4 |

| Specific Heat @20°C, Kj/Kg.K | 1.0 |

| Thermal Shock Resistance, ★ | ★★★★ |

| Max Working Temperature, ℃ | 1320 |

OD*ID*L: (35-220)*(20-180)*(20-1000)mm;

NO.2 Silicon Carbide Kiln Shelves Products (1650°C)

We offer a comprehensive portfolio of advanced silicon carbide shelves tailored for diverse kiln shelf applications, ensuring optimal performance and longevity under extreme thermal and chemical conditions. Our material range includes: OBSIC, SIC, SiSiC/RBSiC, RSiC, NSiC, SSiC. Choose the right materials to extend the service life of your kiln or equipment.

| Item | RSIC |

|---|---|

| Contents | SiC≥99% |

| Bulk Density, g.cm-³ | 2.65-2.75 |

| Apparent Porosity, % | < 15 |

| Modulus of Ruture at 20°C, Mpa | 90-100 |

| Modulus of Rupture at 1200°C, Mpa | 100-110 |

| Hardness at 20°C, Kg/mm² | 1800-2000 |

| Fracture Toughness at 20°C, Mpa*M½ | 1.8-2.0 |

| Thermal Conductivity at 1200°C, W/m.k | 35-36 |

| Thermal Expansion at 20-1200°C, 1x10 */°C | 4.6 |

| Thermal Shock Resistance at 1200°C | Very good |

| Max.working Temperature | 1650°C |

Outer diameter: 142-1050mm;

Inner diameter: 110-930mm;

Overall height: 180-1320mm;

Advantages of Kerui Ceramic Kiln Shelves

-

High-temp

Resistance

Corrosion

Resistance

Wear

Resistance

Good Thermal

Insulation

-

Dimensional

Stability

High

Strength

Environmentally

Friendly

Easy To

Construct

Strict Quality Control of Kerui Ceramic Fiber Products

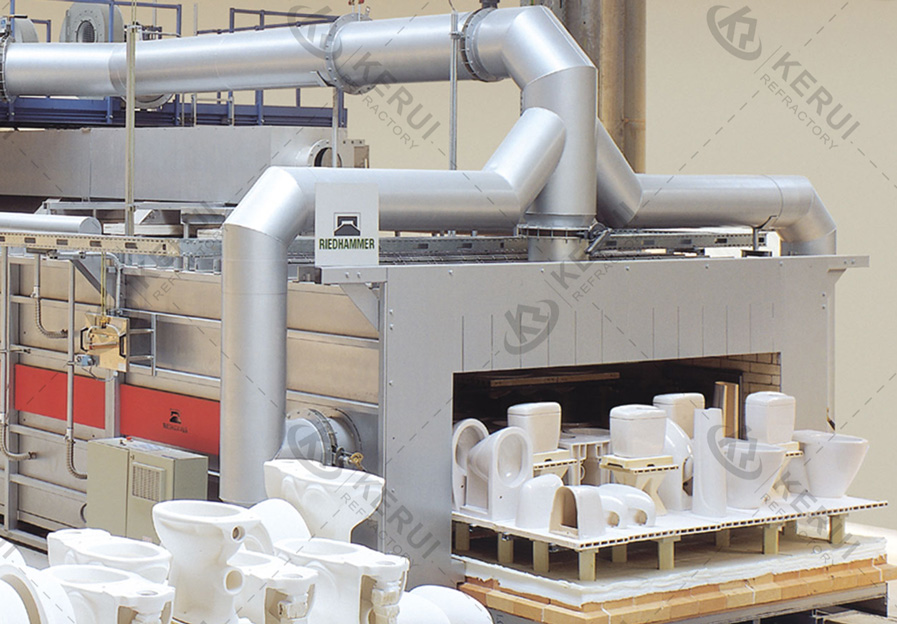

Industrial Applications of Kerui Ceramic Fiber Insulation Products

- Ordinary Ceramic Kiln

- Daily Ceramic Kiln

- Electronic Ceramic Kiln

- Lithium Battery Positive Electrode Material Kiln

- Sanitary Ware Kiln

- Glass Melting Furnaces

- Regenerators

- Lining for Electric Arc Furnaces

- Ladles and Tundishes

- Lining of Blast Furnaces

- Rotary Kilns:

- Preheaters and Coolers

- Cracking Furnaces

- Reformers

- Lining for Aluminum Smelters

- Copper Refining Furnaces

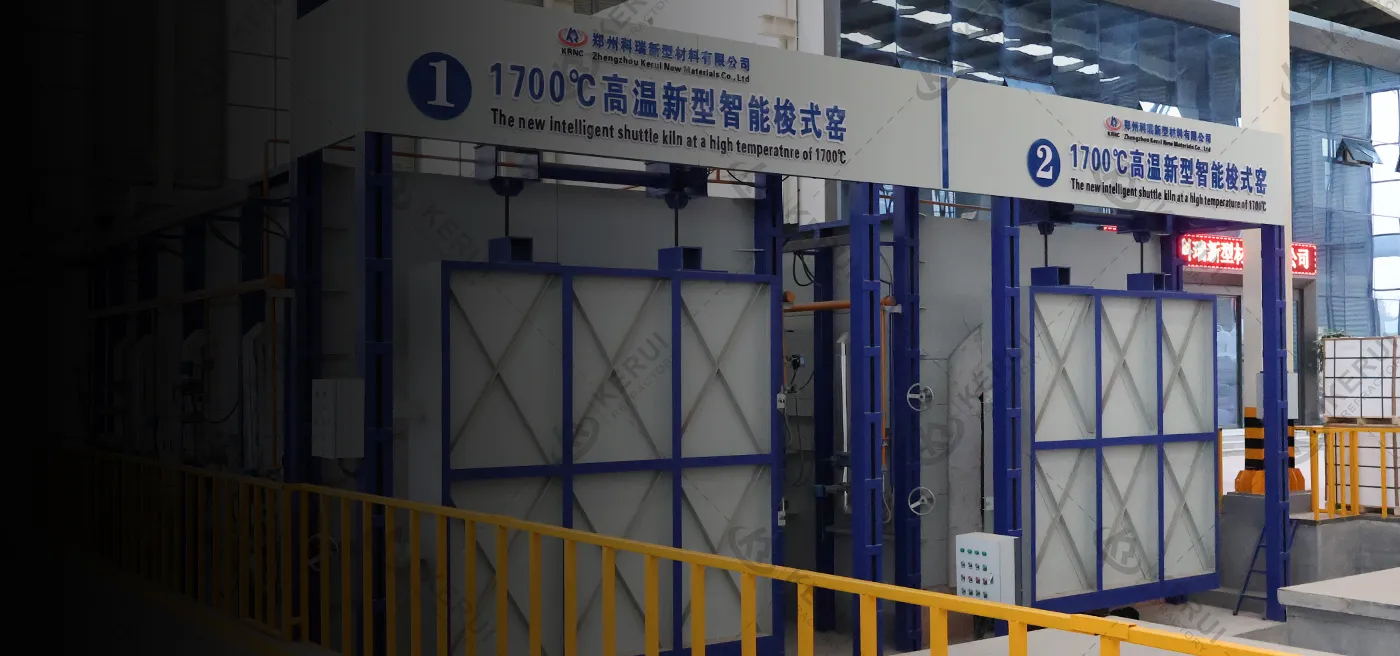

Project Sites of Kerui Customers Over World

Kerui Refractory is a global leader in advanced kiln shelf solutions. Our products serve industries in 50+ countries across five continents. From the demanding environments of the global market, our products improve industries in Southeast Asia, North Africa, Latin America, and beyond. See their projects and reviews:

Kerui Refractory – Your Choice of Ceramic Kiln Furniture

Raw material inspection: All raw materials undergo rigorous multi-dimensional testing before entering the production process.

Automated manufacturing: Factory is equipped with automated machinery to ensure precise and consistent product quality.

Dimensional and physical testing: Finished kiln furniture undergoes comprehensive dimensional and physical testing before being packaged and shipped.

![]()

High-temperature application design: Our engineers can provide design drawings for various high-temperature applications.

Product selection assistance: We can help you determine the right product combination for your needs.

On-site construction guidance: Our construction team can provide on-site guidance to help you complete your high-temperature project quickly and efficiently. See some YouTube videos