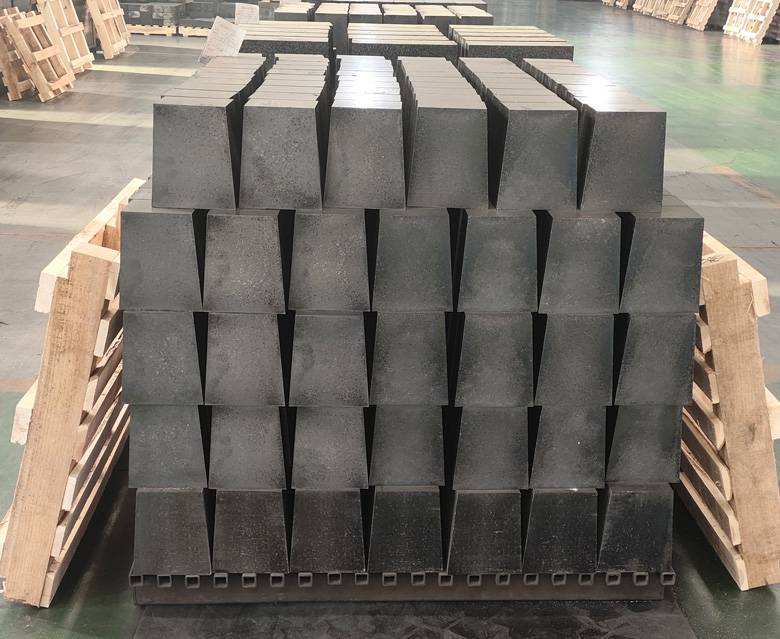

Furnaces are widely used in modern industry. Almost every industry needs high-temperature furnaces to manufacture products. Kerui has 20 years of experience in refractory bricks. We can provide high-quality bricks to customers.

Common Refractory Bricks for Furnaces

There are many different types of furnace bricks.

Alumina type: high alumina bricks, clay bricks, mullite bricks, AZS bricks, alumina silicon carbide bricks, corundum bricks, chrome corundum bricks, and andalusite bricks.

Magnesia type: magnesia bricks, magnesia chrome bricks, magnesia carbon bricks, magnesia alumina bricks, magnesia iron spinel bricks.

Silica type: silica bricks, sillimanite bricks, silicon carbide bricks.

Choose the Suitable Fire Bricks for Furnaces

Choosing suitable bricks for furnaces is the key to prolonging the life cycle of your furnaces. You should select furnace fire bricks according to your industry.

Steel furnaces are prone to select brick that has good wear resistance and thermal shock resistance. In the steel high-temperature equipment, slags will erode the linings of the furnaces. It uses magnesia bricks like magnesia carbon bricks and magnesia chrome bricks. The high alumina bricks and corundum bricks can also used for steel furnaces.

Nonferrous industrial furnaces are prone to use magnesia bricks. Magnesia brick is an alkaline material that has excellent alkaline solution resistance. Magnesia chrome brick and magnesia carbon brick both have good refractoriness and low creep capacity. They can be used for the working linings of furnaces. Besides, high alumina brick and clay brick can be used for the other parts of the furnaces.

Glass furnaces mainly use high-quality silica bricks and fused AZS and alumina bricks in the working linings. They can resist chemical gases and materials. It uses high alumina bricks and clay bricks in the flue parts.

Chemical industrial equipment uses corundum bricks, silica bricks, high alumina bricks, and clay bricks as the linings of furnaces. They can resist thermal shock and chemical erosion.

Energy electricity industry uses silicon carbide bricks, high alumina bricks, and magnesia bricks. They have high refractoriness and good thermal conductivity. So they can effectively reduce heat transfer and enhance energy utilization.

Production Process

Kerui will guarantee every production line has professional quality control personnel to inspect the refractory bricks. We also have high-precision equipment to control the raw materials ratio. Moreover, we have an innovation research and development laboratory to develop refractory materials. We have got more than 15 patent technical certificates.

Service of Kerui

Kerui can provide professional guidance about your industrial furnaces. We have technicians to recommend suitable refractory bricks according to your needs. And we can provide customized service if you need special size bricks. Besides, we have senior industry practitioners who can provide one-stop service to customers. You can buy all the refractory materials in Kerui.