Refractory cement is a unique high-temperature resistant cement. It is usually used to produce refractory castable as a kind of binder. Kerui Refractory, as a manufacturer of refractory materials, offers a variety of models of cement for customers to choose from. Our 1000+ partners are from 50 countries.

- Use Temperature: 1300-1800℃;

- Al2O3: ≥50-80%;

- Compressive Strength (72h): 30-65MPa;

- Initial Setting Time: ≤30-240min;

- Final Setting Time: 90-360min.

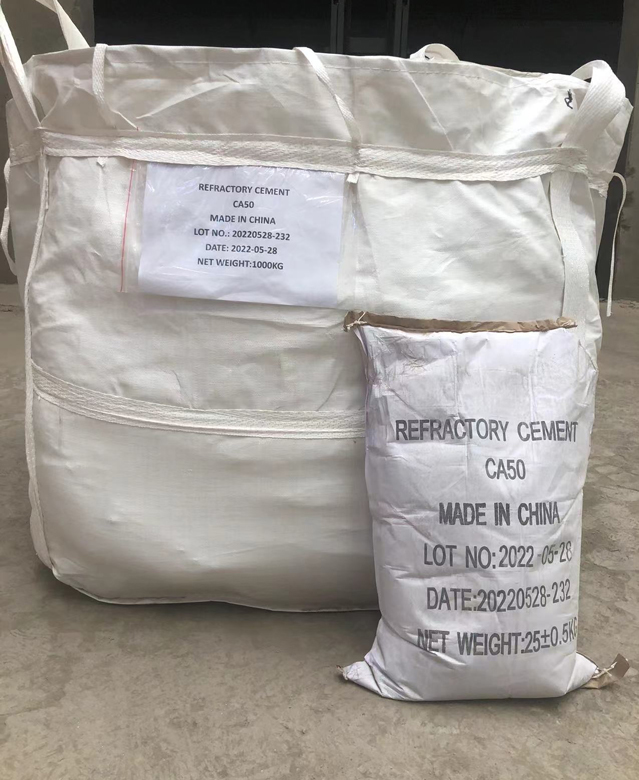

- Packaging: 25kg/bag; 1000kg/bag;

- Delivery: 7-15 working days;

Technical Data of Kerui Refractory Cement for Sale

Kerui Refractory offers three standard cements, including CA50 (1300-1350℃), CA70 (1580-1560℃), CA80 (1750-1800℃). It is all called calcium aluminate cement. The main difference between them lies in the varying content of aluminum dioxide. Within these three types, each one is further subdivided. The main distinction is in the different chemical composition content. Please choose the appropriate types based on your needs.

| Items | CA50-A600 | CA50-A700 | CA70 | CA80 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Values | Typical | Limit | Typical | Limit | Typical | Limit | Typical | Limit | |

| Chemical Composition | |||||||||

| Al2O3 | % | 50-51 | ≥50 | 50-52 | ≥50 | 68-71 | ≥68 | 78-80 | ≥77 |

| CaO | % | 32-35 | ≥32 | 32-35 | ≥32 | 28-30 | ≤30 | 18-20 | ≤20 |

| SiO2 | % | 7.8-8.3 | ≤9.0 | 7.0-7.5 | ≤8.0 | 0.2-0.7 | ≤1.0 | 0.1-0.4 | ≤0.5 |

| Fe2O3 | % | 1.5-2.5 | ≤3.0 | 1.5-2.5 | ≤3.0 | 0.1-0.5 | ≤0.7 | 0.1-0.4 | ≤0.5 |

| Na2O+K2O | % | - | ≤0.5 | - | ≤0.5 | - | ≤0.4 | - | ≤0.4 |

| Physical Properties | |||||||||

| 325 Mesh Residue | % | - | ≤20 | - | ≤15 | - | ≤8.0 | - | ≤5.0 |

| Blaine Fineness (㎡/kg) | % | - | ≥320 | - | ≥350 | 380-420 | ≥350 | 450-500 | ≥450 |

| Initial Setting Time | min | 50-120 | ≥30 | 50-120 | ≥30 | 180-240 | ≥150 | 150-210 | ≥30 |

| Finish Setting Time | min | 90-180 | ≤360 | 120-210 | ≤360 | 240-300 | ≤360 | 210-270 | ≤300 |

| Flexural Strength (24h) | MPa | - | ≥5.5 | - | ≥6.5 | 9-11 | ≥5.0 | 6-8 | ≥4.0 |

| Flexural Strength (72h) | MPa | - | ≥6.5 | - | ≥7.5 | 11-12 | ≥6.0 | 7-9 | ≥5.0 |

| Compressive Strength (24h) | MPa | 45-55 | ≥40 | 50-60 | ≥50 | 45-55 | ≥30 | 40-50 | ≥25 |

| Compressive Strength (72h) | MPa | 50-60 | ≥50 | 60-65 | ≥60 | 55-65 | ≥40 | 50-60 | ≥30 |

Introduction of Kerui Refractory Cement

Kerui refractory cement is mainly made of bauxite and other components. It is a new type of high-temperature resistant material. And it is a water-hardening cementitious material with an alumina content of over 50%. So, it has excellent heat resistance performance. It is widely used in high-temperature industries as a high-quality additive material or adhesive. And it also is the the refractory castable.

CA50

CA50 cement has an alumina content mainly above 50%. It has a short initial setting time and strong rheological properties. It is suitable for various fast and durable casting methods.

- A600 cement has rapid hardening characteristics and a high rate of heat release during hydration. It is cost-effective and widely used as a primary component in cement casting materials, such as high alumina casting materials and slag blocking balls.

- A700 cement has a high alumina content and stable hardening performance, primarily used in low cement casting materials.

- A900 cement has low impurity content and high alumina purity. It exhibits good flexural and compressive strength. Therefore, it is used in applications that require stable performance.

CA70

CA70 insulating refractory cement has an alumina content mainly above 68% and contains 28-30% calcium oxide. This cement has better flexural strength. Depending on the fineness, it is mainly divided into four types:

- CA70 cement’s refractoriness and solidification effect are enhanced due to the increase in alumina and calcium oxide content. It is used in low cement, ultra-low cement, self-flowing castables, and other high-performance refractory materials.

- CA70W cement has moderate fineness, short setting time, and high strength. It is suitable for use in low-temperature environments, rapid installation, emergency situations, etc.

- CA70S cement has moderate fineness, strong flowability, long service life, and a longer setting time.

- CA71 cement has a larger fineness, longer setting time, and the best strength performance. It is suitable for use in environments with strong mechanical forces.

CA80

CA80 heat refractory cement has an alumina content mainly above 78.0%. It includes the following two categories.

- CA80 cement has a short setting time and good mid-temperature strength. It is used for conventional castables and low cement castables.

- CA80S cement has a longer setting time and good flowability. It is suitable for use in high-temperature environments, such as during summer.

Advantages of Kerui Monolithic Refractory Cement

High-temperature Resistant

Kerui cement has strong refractoriness. It can withstand temperatures ranging from 1200 to 1800 degrees Celsius. Additionally, it has excellent thermal shock resistance. Even with rapid temperature changes, the volume of refractory cement changes minimally. It is suitable for various high-temperature industrial environments.

Strong Mechanical Forcen

Kerui cement has strong wear resistance, compressive strength, and flexural strength. It has a high density. These features ensure durability in high-temperature industries. In abrasive environments, this monolithic refractory can help extend the lifespan of high-temperature equipment.

Corrosion Resistance

Refractory cement exhibits strong resistance to chemical erosion from slag. It can maintain good performance and structure in chemically corrosive environments. It is without negatively impacting equipment. This is crucial in industrial applications.

Strong Adhesion

Kerui cement powder has excellent bonding properties. In high-temperature environments, it can adhere to the surfaces of various materials. This ensures the stability and integrity of the overall structure of high-temperature equipment. This characteristic is essential for the effectiveness of equipment operating in high-temperature conditions.

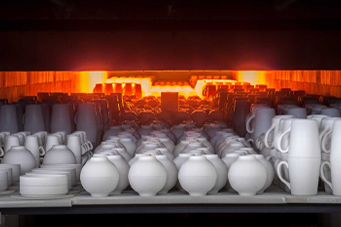

Wide Applications of Kerui Refractory Cement

Kerui refractory cement is high-temperature resistant and has high mechanical strength. It is suitable for various industries, such as the refractory materials industry, construction industry, engineering, steel, power, petrochemical, cement industry, and so on. It is used for casting materials, high-temperature kilns, boilers, incinerators, linings, fixed parts, fireplaces, chimneys, road construction maintenance, and so on. It can protect the surrounding structures of equipment from heat damage. And it is also an important repair material. If your industry has a need for cement, please contact us. We will provide detailed solutions and products based on the usage scenarios and temperatures.

Factors for Selecting Suitable Refractory Cement

Ingredients

Different ingredients affect the performance of refractory cement. A higher content of alumina can enhance refractoriness and high-temperature resistance. Silica helps improve the strength and stability of the cement. Calcium oxide contributes to the solidification and hardening effects. Customers can choose the appropriate cement based on their requirements for high temperatures and strength.

Fineness

Fineness refers to the size of the particles in refractory cement materials. The fineness of cement affects bonding performance, hydration reactions, and strength. When the particle size is finer, there are fewer gaps in the refractory mix. This results in higher density and strength. With a larger surface area, hydration effects and strength are enhanced. When selecting cement, we provide detailed guidance to our customers.

Setting Time

Setting time refers to the time required for cement to mix with water and fully cure. It includes initial setting time and final setting time. The final setting time of refractory cement provided by Kerui Refractory is between 90-360 minutes. Quick-drying cement aids in construction and industrial building and repairs.

Kerui Refractory – A Leading Top Refractory Cement Manufacturer

Kerui Refractory, as a manufacturer and supplier of refractory cement, has its own factory and over 200 employees. Our strong production capabilities and customer-centric service have led many customers to choose us.

Product Control

- Kerui Refractory’s fully digitalized production management workshop strictly produces refractory cement that meets the required standards.

- Raw materials and finished products undergo chemical and physical laboratory testing before being sent to customers.

- Kerui research and development team continuously innovates composite refractory materials to provide innovative solutions for customers in high-temperature industries.

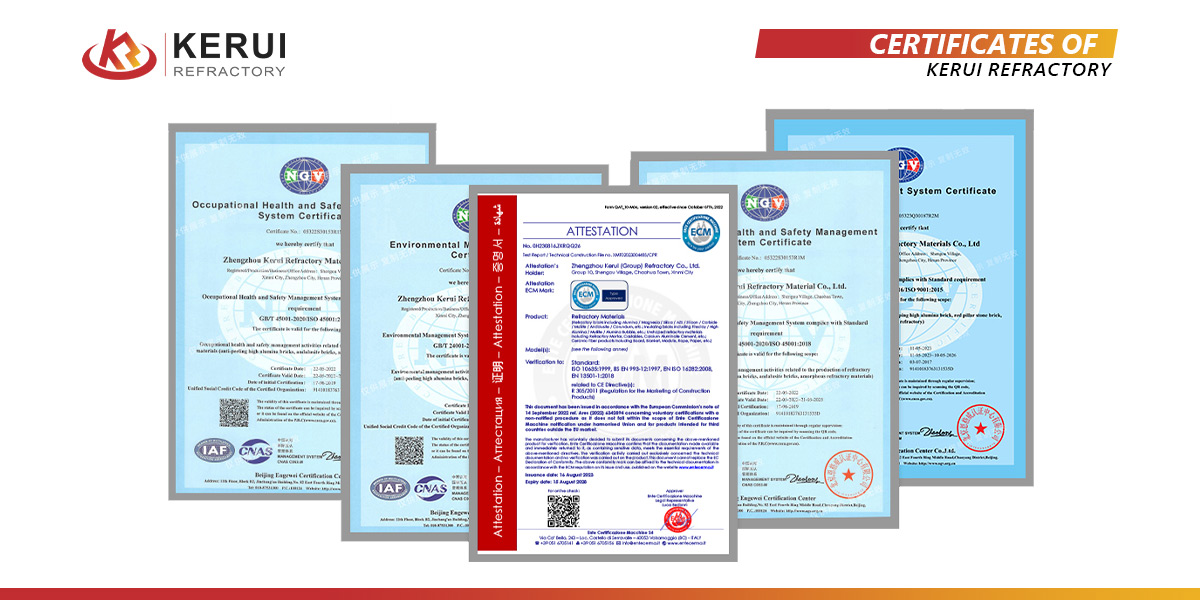

Company Strength

- Ranked in the top three in the same industry in China, Kerui Refractory has high brand recognition.

- We hold over 20 refractory material technology patents, ISO certifications, and have an annual production capacity of up to 250,000 tons.

- Refractory cement is exported to over 30 countries. This showcases our extensive export experience. See the latest cases.

Service

- Professional international business managers provide one-on-one consultation services.

- We offer comprehensive refractory solutions to meet customers’ needs for refractory materials, solutions, and construction.

- We provide the best packaging, transportation, and after-sales services.

Contact Kerui Refractory to Get Refractory Cement

Kerui Refractory supplies high-quality refractory cement necessary for a variety of industrial and high temperature industry applications. Our cement quality and production capabilities are guaranteed. Invest in Kerui Cement for superior performance, long-lasting results and comprehensive service now!