Alumina silica refractory brick is a type of acid-resistant and alkali-resistant refractory material. It is mainly made of silicon dioxide, which is as high as 94%. They have high refractoriness, high load-softening temperature, and stronger slag resistance, thermal shock resistance and mechanical properties than other refractory bricks. It is widely used in kiln linings, pipelines, etc.

- SiO2: ≥25.0-99.3%;

- Bulk Density: 2.3-2.6g/cm³;

- Flexural Strength: 7-9MPa;

- Compressive Strength: 40-70MPa;

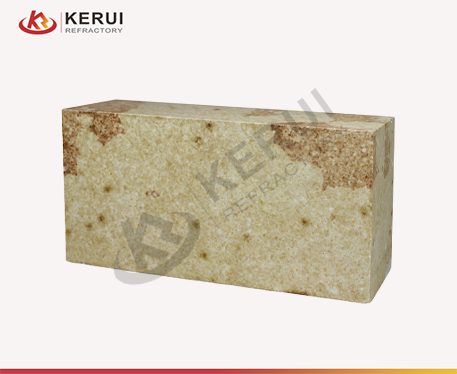

What is Alumina Silica Refractory Brick?

Alumina-silica refractory bricks are a type of refractory brick made by firing a mixture of Al2O3, SiO2, and additives. According to the composition content of alumina and silicon oxide, Kerui Refractory offers the following types of alumina-silica refractory bricks:

Advantages of Alumina Silicate Brick

- High Refractoriness: Alumina silicate firebricks have a high melting point, making them suitable for various high-temperature industrial applications.

- Wear Resistance: Alumina silica fire bricks can be used in environments with high mechanical strength. This kind of silica firebrick have high wear resistance.

- High Strength: At high temperatures, alumina silicate refractory bricks do not easily fall off. They have strong compressive and flexural strength.

- Corrosion Resistance: It can resist the corrosion of acidic and alkaline media at high temperatures.

- Strong Thermal Shock Resistance: Alumina silica firebrick do not deform at high temperatures and maintain their dimensional stability.

- Good Thermal Conductivity: It can improve the thermal efficiency of kilns and other high-temperature equipment.

Applications of Alumina Silicate Fire Brick

- Metallurgical Industry: Electric furnace, open hearth furnace, steelmaking furnace, ironmaking furnace, converter, heating furnace, etc.

- Building Materials Industry: Cement kiln, glass kiln, lime kiln, ceramic kiln, tunnel kiln, etc.

- Chemical Industry: Ammonia synthesis furnace, fertilizer furnace, synthetic rubber furnace, etc.

- Power Industry: Boiler, flue gas desulfurization unit, garbage incineration furnace, etc.

For a fast and competitive quotation on high-quality refractory products, contact Kerui Refractory today. Our expert team is ready to assess your requirements and provide customized solutions tailored to your project’s needs. We ensure quick response times, cost-effective pricing, and reliable technical support. With years of industry experience and a commitment to customer satisfaction, Kerui Refractory delivers durable and high-performance materials for steel, cement, glass, and other high-temperature applications. View more videos about company and products.