High alumina insulation brick is a type of lightweight insulating bricks made with alumina as the main raw material. Its excellent fire resistance, thermal insulation performance, and light weight make it the choice for many high temperature industries. Kerui Refractory offers high-quality bricks at factory prices to 1000+ partners over the world.

- Al2O3: ≥48%;

- Fe2O3: ≤2.0%;

- Bulk Density: ≤0.8-1.2g/cm³;

- Cold Crushing Strength: 1.2-4.5MPa;

- Permanent Linear Change: -2-1.0% T/ºC*12h.

- Size: 230*114*65mm (standard)/other sizes;

- Delivery: 15-30 working days;

- Price: Low EX-factory price;

Parameters of Kerui High Alumina Insulation Bricks

| Item/Grade | LG140-1.2 | LG140-1.0 | LG140-0.8L |

|---|---|---|---|

| Al2O3, % | ≥48 | ||

| Fe2O3, /% | ≤2 | ||

| Bulk Density, g/cm³ | ≤1.2 | ≤1 | ≤0.8 |

| Cold Crushing Strength, MPa | ≥4.5 | ≥3.5 | ≥2.5 |

| Permanent Linear Change, % (T/℃*12h) | 1400 | 1350 | 1250 |

| -2~1.0 | |||

| Thermal Conductivity Coefficient, W/(m·K) Average Temperature (350±25℃) | ≤0.55 | ≤0.50 | ≤0.35 |

Kerui High Alumina Lightweight Bricks

Kerui high alumina insulation bricks are a type of high-temperature insulation product made from high-quality alumina, clay, and other raw materials. Its main component is alumina, with a content of at least 48%. In addition, it also contains a small amount of iron oxide, calcium oxide, magnesium oxide, etc. Therefore, this insulation brick has comprehensive performance.

Advantages of Kerui High-alumina Insulation Bricks

- High refractoriness: The refractoriness of high alumina insulation bricks is generally between 1580 and 1750°C. The refractoriness is higher than that of other insulating brick. This makes them suitable for use in high temperature environments.

- Good thermal insulation performance: The thermal conductivity of high alumina insulation bricks is between 0.2 and 0.55 W/(m·K). The thermal conductivity is lower than that of clay insulation bricks and silica insulation bricks. This means that they have excellent thermal insulation properties.

- Light weight: The density of alumina insulation bricks is between 0.5 and 1.2 g/cm³. This makes them lightweight and easy to handle. It improves construction quality.

- High strength: The compressive strength of high alumina insulation bricks is between 1.0 and 2.0 MPa. This makes them strong and durable, with a long service life in high temperature mechanical applications.

- Good chemical stability: Alumina has good chemical stability. This feature helps to resist corrosion from acidic and alkaline slags.

Applications of Kerui High Alumina Insulation Bricks

- Metallurgical industry: The inner lining of steelmaking furnaces, reheating furnaces, annealing furnaces, sintering furnaces, blast furnaces, converters, etc.

- Chemical industry: The insulation and lining of chemical reactors, synthesis furnaces, decomposition furnaces, coking furnaces, etc.

- Construction materials industry: Ceramic kilns, tunnel kilns, roller kilns, shuttle kilns, wall kilns, the thermal insulation and fire protection of buildings, etc.

- Power industry: The insulation and lining of boilers, chimneys, turbines, and other power plant equipment.

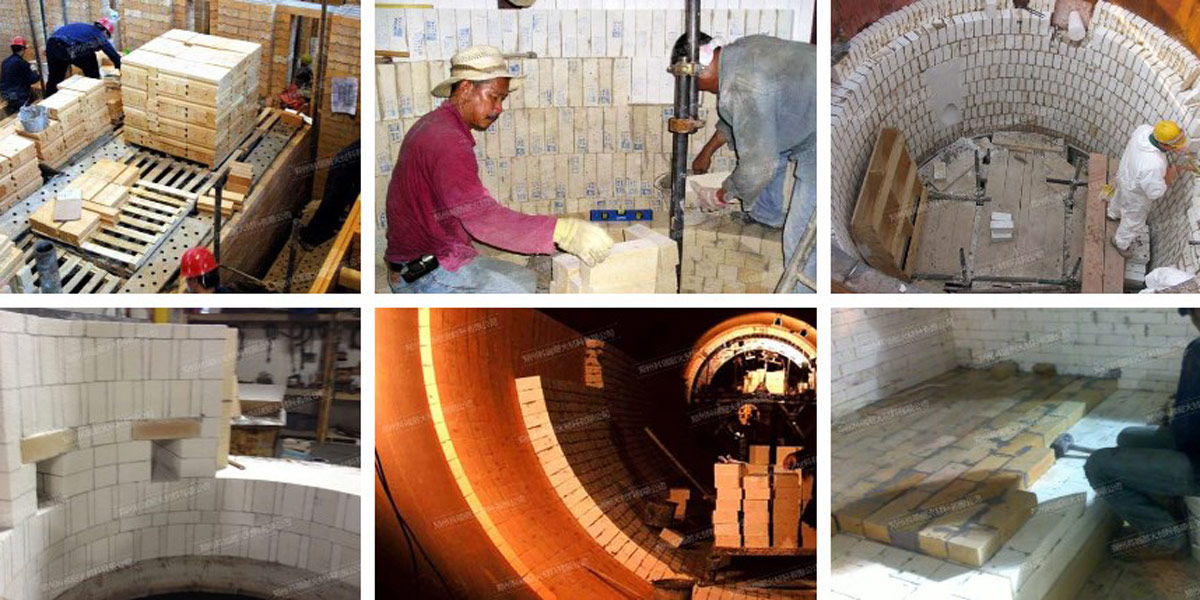

1000+ Customers of Kerui High Alumina Insulation Brick

Over 1000+ partners have chosen Kerui refractory products. These partners come from all over the world, including Russia, Italy, Uzbekistan, Egypt, South Korea, Australia, Saudi Arabia, the United Arab Emirates, Jordan, Brazil, and so on. We provide high-quality products and suitable solutions for these partners. They have repeatedly chosen to collaborate with us.

Choose the Leading Manufacturer – Kerui Refractory

As a top refractory manufacturer, Kerui provides high-quality high-alumina insulation bricks and high-temperature kiln solutions. If you have any requirements, please send us the details. Our professional technical team will provide you with technical specifications. Additionally, our shipping team will ensure strict packaging to guarantee that you receive bricks of high quality intact. This will not delay your project timeline. View more pictures on Kerui Pinterest.