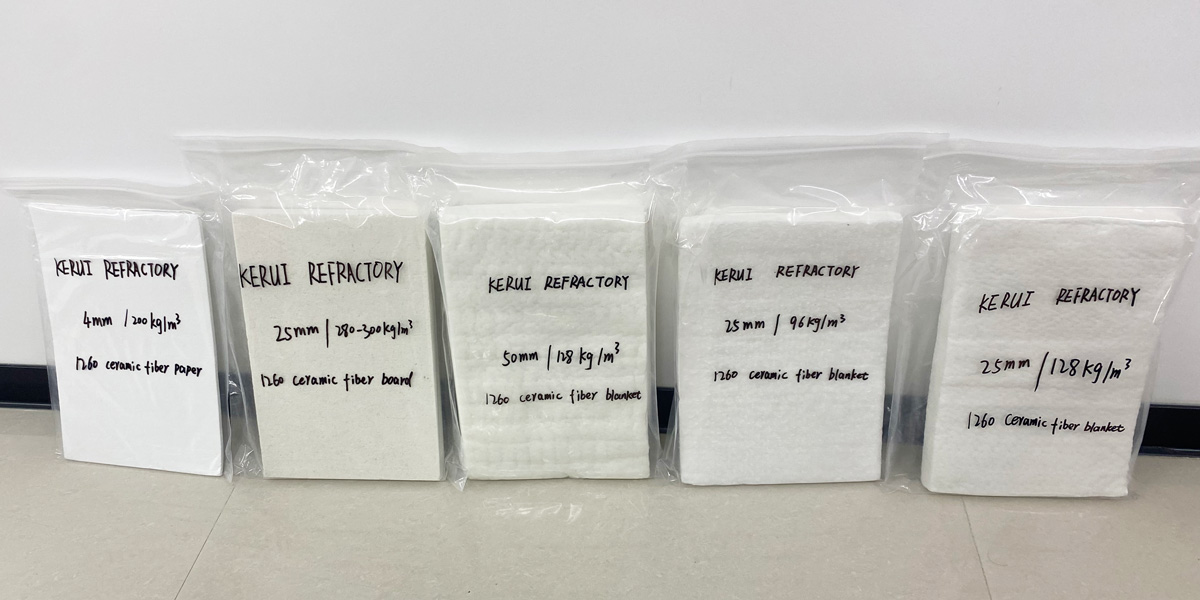

Refractory blanket has excellent thermal insulation properties. It is 40% more energy-efficient than traditional refractory materials. Kerui offers a variety of blanket specifications, including different thicknesses, lengths, widths, and operating temperatures, among others. Kerui guarantees product quality and provides various certifications and documents. We maintain good cooperative relationships with several internationally renowned companies.

- Classification Temperature: 1050-1430ºC/1922-2606°F;

- Bulk Density: 96-160kg/m³; 5-10lbs/cf;

- Length: 7200/3600mm/Customizable;

- Width: 600/610/1220mm/Customizable;

- Thickness: 6-60mm/Customizable;

- Document: MSDS supporting;

- Certificate: ISO9001/ISO14001/OHSAS18001/CE/SGS;

- Shipment: 7-15 working days;

Technical Specifications of Refractory Blanket

| Item | Common Type | Standard Type | High Purity Type | High Alumina Type | Zirconium Containing Type |

|---|---|---|---|---|---|

| Classification Temperature, ℃ | 1050 | 1260 | 1260 | 1350 | 1430 |

| Service Temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Bulk & Density, kg/m³ | 96-128 | 96-128 | 96-128 | 128-160 | 128-160 |

| Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) | -3 (1250℃) | -3 (1350℃) |

| Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) 0.22 (1000℃) | 0.132 (600℃) 0.22 (1000℃) | 0.76 (800℃) 0.20 (1000℃) |

| Strength of Extension, Mpa | 0.08-0.12 | ||||

| Al2O3, % | 44 | 46 | 47-49 | 52-55 | 39-40 |

| Al2O3+SiO2, % | 96 | 97 | 99 | 99 | - |

| Al2O3+SiO2+ZrO2, % | - | - | - | - | 99 |

| ZrO2, % | - | - | - | - | 15~17 |

| Fe2O3, % | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

| Size, mm | Standard Size: 7200/3600*610/1220*6-60; Customized Sizes | ||||

Types of Kerui Refractory Insulation Blanket

| Types | Common Grade | Main Ingredients | Features |

| Ceramic Fiber Blankets | 1050 Refractory Blanket; 1260 Refractory Blanket; 1260 Refractory Blanket; 1350 Refractory Blanket; 1430 Refractory Blanket; Refractory Blanket with Single-sided Foil; Ceramic Fiber Blanket with Double-sided Foil; |

Aluminum oxide and silicon dioxide | Low density; good flexibility; easy to cut and shape. |

| Soluble Fiber Blanket | 1300C Refractory Bio-soluble Fiber Blanket | Water-soluble fiber | It can be degraded in human body fluids and is environmentally friendly. |

| Polycrystalline Mullite Fiber Blanket | 1600c Polycrystalline Mullite Ceramic Fiber Blanket | Mullite | The fiber structure is dense and high in strength, making it suitable for harsher high-temperature environments. |

Note: Chromium-containing ceramic fiber blankets are polluting to the environment.

Production Process of Kerui RefractoryBlankets

Kerui primarily employs two production processes: blown blankets and spunbonded blankets. The ceramic fiber spunbonded blanket has the features of the longer fiber strands and lower thermal conductivity. It offers superior insulation performance compared to the ceramic fiber blown blanket. As a result, the ceramic fiber spunbonded blanket is a common choice for insulation in pipeline construction.

Features of Refractory Blankets Insulation

- Low Thermal Conductivity: Excellent insulation properties that effectively reduce heat loss.

- Outstanding Chemical Stability: Corrosion-resistant and suitable for various chemical environments.

- Excellent Thermal Stability: Maintains performance stability at high temperatures, with dimensional stability under heat.

- High Tensile Strength: Resistant to stretching and less prone to breaking.

- Vibration Resistance: Maintains performance even in vibrating environments.

- Low Heat Capacity: Responds quickly to temperature changes, saving energy.

- Excellent Sound Absorption: Reduces noise transmission.

- Easy to Handle: Lightweight and flexible for construction operations.

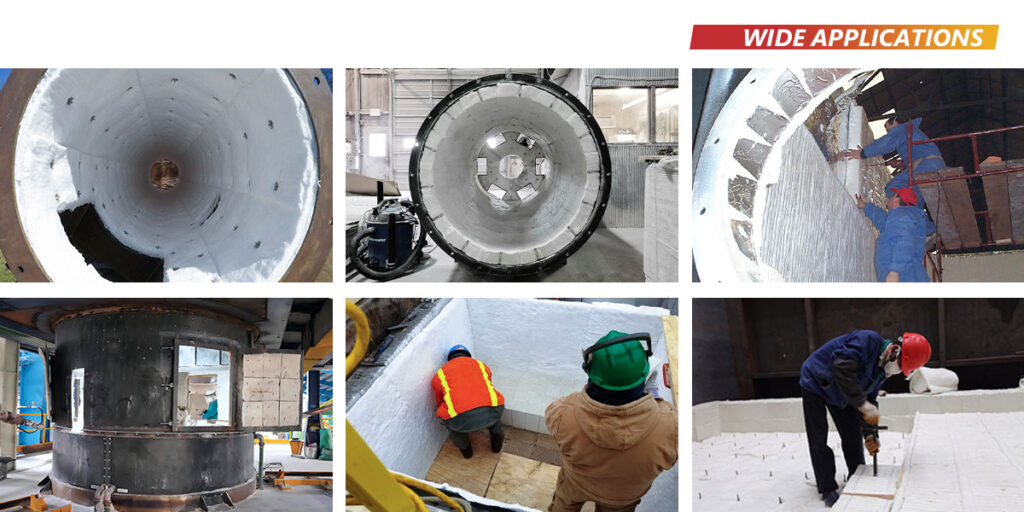

Applications of Refractory Blankets

- Insulation and Lining Materials: The linings of furnaces, kilns, reformers, and boilers; reusable insulation for steam and gas turbines; and high-temperature kiln insulation.

- Seals and Gaskets: These include furnace door linings, high-temperature gaskets, expansion joint seals, and removable insulation blankets to alleviate welding stress.

- Specialized Applications: Covers nuclear insulation applications, thermal insulation for reactors, glass furnace crown insulation, and linings for outdoor steam generators.

- Fire Protection and Filtration: Involves fireproofing for pressure and low-temperature containers, sealing for soaking pits, high-temperature filtration, and linings for incinerators and chimneys.

- Mold Packaging: Encompasses packaging for investment casting molds and removable mold packaging solutions.

Global Cases of Kerui Refractory Blankets

Kerui high heat insulation blankets are shipped globally to over 50 countries, including Saudi Arabia, Lebanon, South Africa, the Netherlands, Australia, New Zealand, Malaysia, Taiwan, Iraq, Oman, Kazakhstan, and so on.

Customers have highly praised the quality and service of Kerui products, with 70% of them choosing to repurchase.

Choose Kerui Refractory to Get Your Ideal Refractory Blanket

- High production productivity;

- Advanced production equipment;

- Strict quality control system;

- Fast delivery and complete packaging;

- Optimal freight routes and LCL solutions;

- Insulation solutions;

- ISO14001, ISO900, CE, etc;

View more video about Kerui on Youtube.