High alumina fire brick has a high alumina content. This brick is suitable for various high-temperature kilns. Kerui has a factory with a strict quality control system. Kerui offers a variety of series. In addition, to meet the special needs of customers, Kerui supports the customization of special-shaped bricks.

- Refractoriness: Above 1770ºC;

- Al2O3:≥48-80%;

- Bulk Density: 2.1-2.7g/cm³;

- Refractoriness Under Load: 1420-1530ºC;

- Apparent Porosity: 19-26%;

- Size: 230*114*65mm (standard) and other sizes;

Specifications of High Alumina Fire Brick

| Item | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-60 | LZ-55 | LZ-48 | |

|---|---|---|---|---|---|---|---|---|

| Al2O3, /% | ≥ | 80 | 75 | 70 | 65 | 60 | 55 | 48 |

| Apparent Porosity, % | ≤ | 21 | 24 | 24 | 24 | 26 | 22 | 22 |

| Cold Crushing Strength, MPa | ≥ | 70 | 60 | 55 | 50 | 45 | 45 | 40 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1530 | 1520 | 1510 | 1500 | 1430 | 1450 | 1420 |

| Permanent Linear Change, % | 1500℃*2h -0.4~0.2 | 1450℃*2h -0.4~0.1 |

||||||

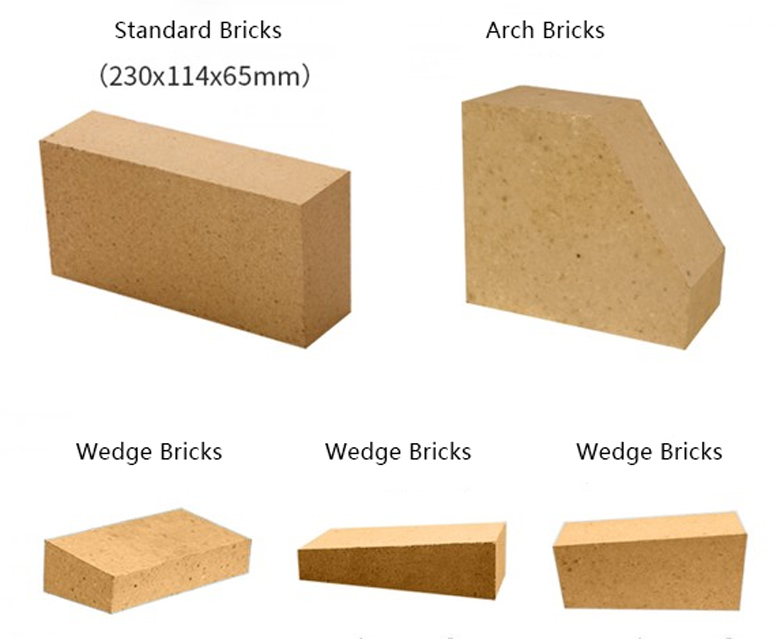

A Variety of High Alumina Fire Bricks

High-alumina bricks are made from high-grade bauxite, bonded clay, electric-melted corundum, electric-melted mullite, and other raw materials with a high alumina content, which are molded and fired. At firing temperatures of 1500-1600°C, they have uniform density and good quality. To meet the needs of various industries and furnaces, we offer the following types:

- SK Series: SK36, SK38, SK40, etc.;

- Duty Grade: High Duty Fireclay Brick, Medium Duty Firebrick, Low Duty Firebrick;

- Special Grade Series: We also offer special high-alumina bricks: LZ-80, LZ-83, LZ-85;

- T Series: T3, T6, T14, T19, T20, T30, T38, T39, etc.;

- G Series: G1, G2, G5, G6, etc.

- GL Series: GL-65/GL-55/GL-48. These are commonly used grades for blast furnaces.

- RL Series: RL-65/RL-55/RL-48. These are commonly used grades for hot blast stoves.

- DL Series: DL-80/DL-75/DL-65. These are commonly used grades for electric furnace roofs.

- CL Series: CL-48/CL-75/CL-65. These are commonly used grades for steel ladles.

- SL Series: SL-48/KL-48/XL-48/ZL-48. These are commonly used grades for ladle lining in steel casting.

- RLZ Series: RLZ-65/RLZ-55/RLZ-48. These are commonly used grades for resistance furnaces.

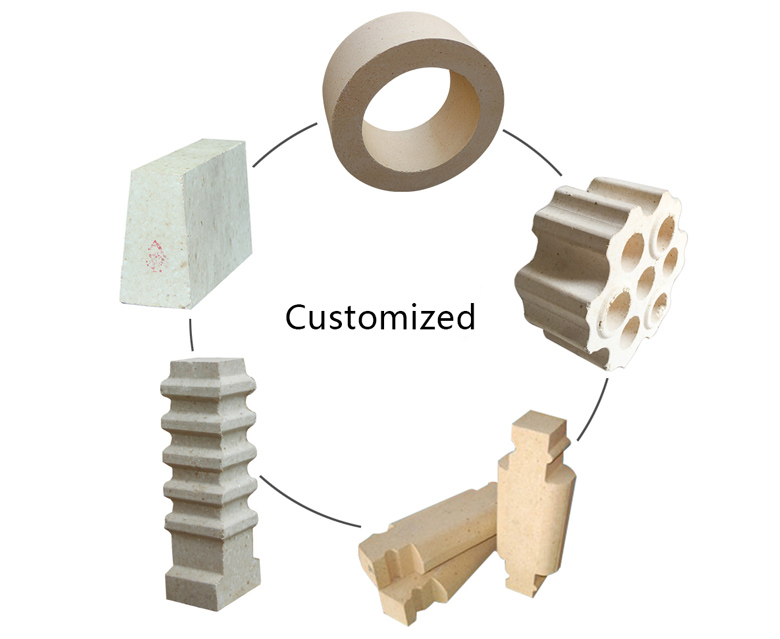

Standard Sizes and Special-shaped Bricks

- Standard shapes: Standard shapes include straight bricks, anchor bricks, checker bricks, arch foot bricks, axe-shaped bricks, half-moon shaped bricks, and so on.

- Standard size: The standard size is 230*114*65mm.

- Customized special-shaped bricks: To meet the special needs of customers, we can customize special-shaped bricks based on customer drawings.

Strict Quality Control of High Alumina Fire Bricks

- Certification: ISO 9001, ISO 14001, and other international quality management system certifications.

- Production Control: Raw material inspection, precise raw material proportioning, uniform pressing, firing temperature control, finished product inspection, etc.

- Professional Testing: Professional third-party testing reports.

Features of Kerui High Alumina Bricks

High refractoriness;

High softening temperature under load;

Good slag resistance;

Great thermal shock stability;

Good dimensional stability;

Excellent chemical corrosion resistance;

Good wear resistance;

Long service life.

Video of High Alumina Fire Bricks

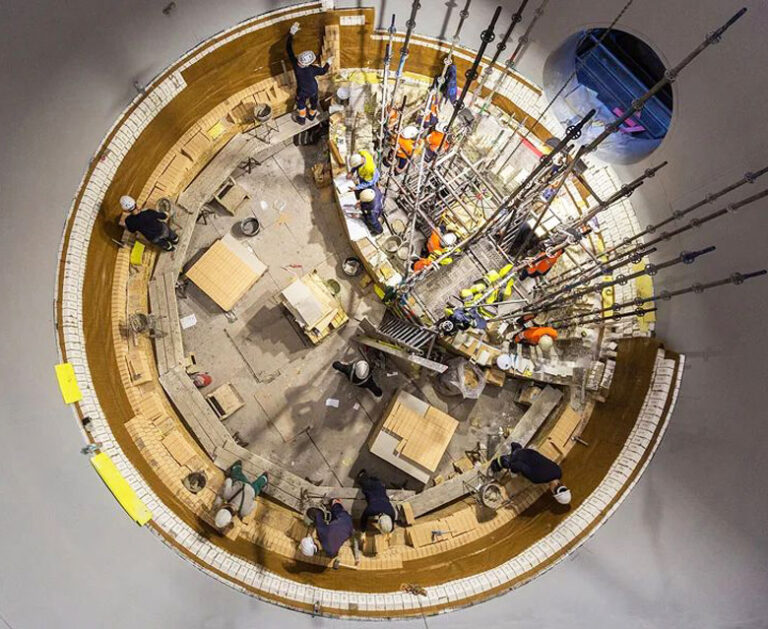

Applications of High Alumina Fire Refractory Bricks

Furnace linings: The applications of high-alumina bricks are for the linings of blast furnaces, hot blast stoves, electric furnace roofs, steel ladles, cement kilns, glass kilns, etc., to resist high temperatures and slag erosion.

- Regenerator chambers: Checker bricks for regenerative furnaces, used for heat storage and heat release, require refractory bricks with good thermal stability.

- Casting systems: Tapered plugs and nozzle bricks used in casting systems require refractory bricks with good thermal shock resistance and wear resistance.

- Replacement bricks: High alumina bricks can replace areas that originally used silica bricks or fireclay bricks, improving the service life of the equipment.

Packaging and Shipping of High Alumina Firebricks

The fumigated wooden pallets is the standard packaging. In addition, we can also assist customers with customized packaging.

For products in stock, the shipping lead time is typically 15-30 working days.

Shipment of Kerui High Alumina Firebricks to Multiple Countries

Due to their excellent quality and service, over 50 global customers have chosen Kerui high-alumina bricks, including those in South Korea, Morocco, Brazil, Thailand, Russia, Costa Rica, Kazakhstan, South Africa, Tajikistan, Iraq, Vietnam, and so on.

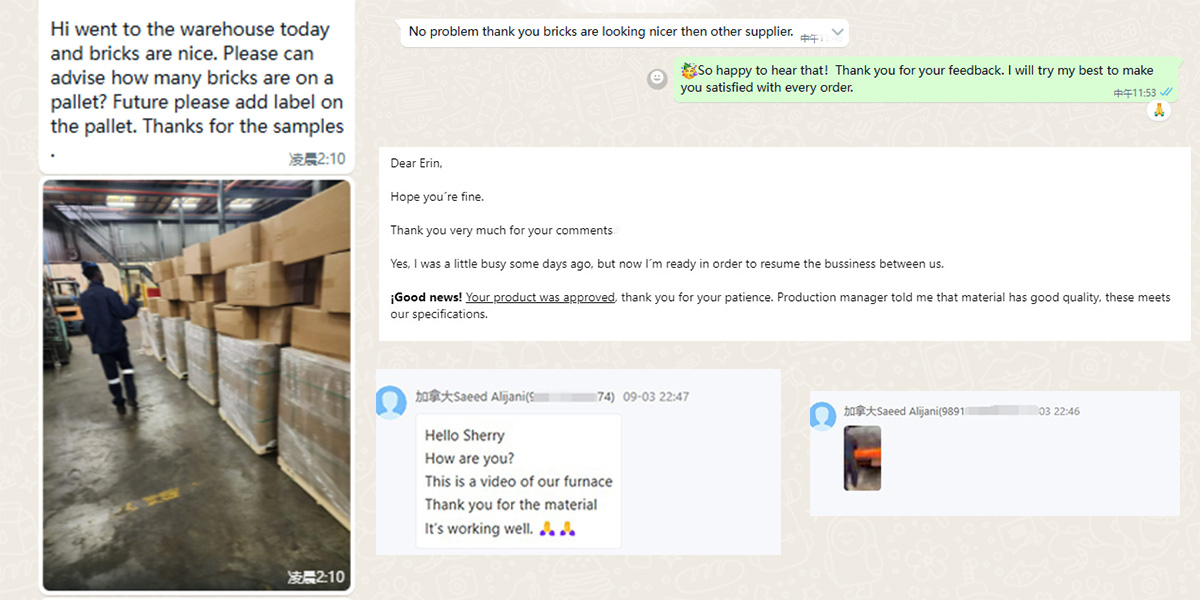

Positive Feedback on High Alumina Bricks from Customers

These customers have provided positive feedback to Kerui after receiving and using the products.

Note: See more YouTube videos about cases and products.