Chrome brick offers excellent thermal stability, slag resistance, and mechanical strength. It is composed primarily of chromium oxide (Cr₂O₃) and other refractory aggregates. KERUI provides different types of bricks with factory price to meet the needs of customers in different industries.

Types of Kerui Chrome Brick

Advantages of Kerui Chrome Bricks

| Types | Magnesia Chrome Brick | High Chrome Refractory Brick | Chrome Corundum Fire Brick |

| Main Composition | MgO + Cr₂O₃ (10-30%) | Cr₂O₃ (>90%) | Al₂O₃ + Cr₂O₃ (15-30%) |

| Max Service Temperature | Up to 1700°C | Up to 1800°C | Up to 1650°C |

| Thermal Shock Resistance | Good | Moderate | Excellent |

| Corrosion Resistance | Strong against basic slags | Excellent against acidic slags | Good in both acidic and basic environments |

| Mechanical Strength | High compressive strength | Very high wear resistance | Balanced strength and toughness |

| Key Advantages | High refractoriness; Good thermal stability; Cost-effective for cement kilns; |

Extreme corrosion resistance; Long lifespan in aggressive conditions; Low porosity; |

Superior thermal shock resistance; Versatile for rapid heating/cooling cycles; Good slag resistance; |

Applications of Kerui Chrome Refractory Brick

| Brick Types | Magnesia Chrome | High Chrome | Chrome Corundum |

| Primary Applications | Cement rotary kilns; Non-ferrous smelting furnaces; Steel ladles; |

Coal gasifiers; Glass melting furnaces; Waste incineration linings; |

Petrochemical reactors; Incinerators; High-temperature boilers. |

Customized Chrome Brick Production

Kerui’s advanced production line supports tailored solutions, including:

- Adjustable Cr₂O₃ content (30%-95%).

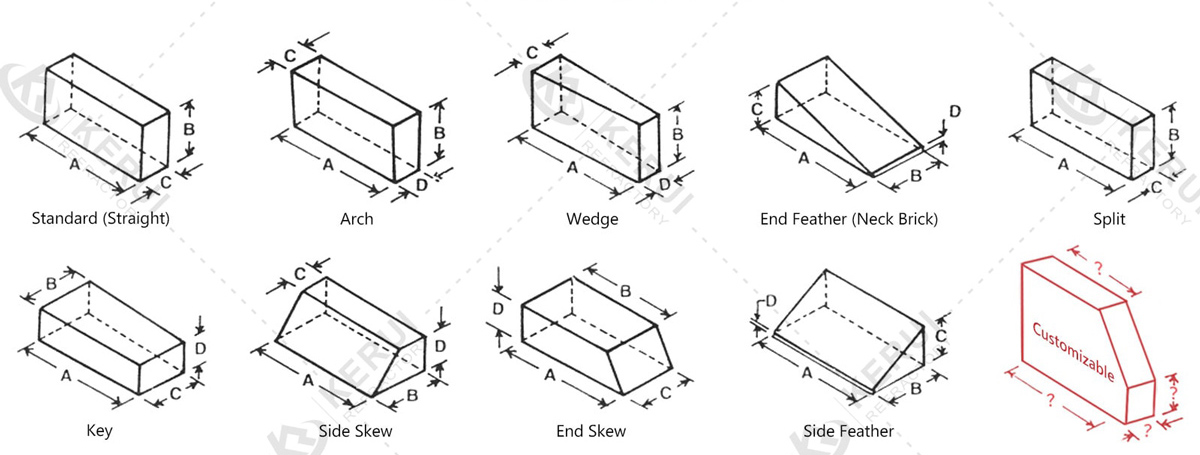

- Various refractory brick shapes and sizes (standard or custom dimensions).

- Enhanced properties for specific thermal or chemical environments.

Packaging of Chrome Bricks for Safe Delivery

To ensure product integrity during transit, Kerui uses:

- Wooden pallets with steel strapping.

- Waterproof and shock-resistant wrapping.

- Custom packaging upon request.

Kerui Chrome Bricks Applied to the Global World

Kerui Refractory is a trusted supplier of bricks worldwide. We provide high-quality products for diverse industrial needs. Our bricks are exported to over 30 countries, ensuring reliability in extreme conditions.

Kerui Refractory is Worth Your Choice

Strong Production Strength

- Owned factory: strictly control the production process to ensure product quality.

- Intelligent equipment: efficient and accurate production, improve product consistency and reliability.

- Customized service: flexible adjustment according to customer needs to meet personalized requirements.

Professional Solution

- Precisely match demand: scientifically calculate the amount, avoid waste, and optimize costs.

- Model recommendation: recommend the most suitable product according to the working conditions to improve the use effect.

- One-stop service: from selection to logistics, worry-free throughout the process, saving time and effort.

Contact Kerui Refractory to Get Chrome Bricks

Kerui brick remains a critical material for high-temperature industries due to its durability and resistance to harsh conditions. Kerui’s expertise in manufacturing and customization ensures that clients receive optimized solutions for their specific applications. For reliable performance and global supply, Kerui stands as a dependable partner in refractory solutions. View more videos on Youtube.