Ceramic Fiber Mat

Ceramic fiber mat represents a class of high-performance thermal insulation materials engineered for demanding applications across a wide range of industries. These mats are typically composed of lightweight, interlocking ceramic fibers that are needled together to form a flexible, resilient, and thermally efficient structure. Kerui provides high-quality mats with different specifications.

- Free Sample:

- Available

- Document:

- MSDS supporting

- Performance Test:

- Support

- Shipment:

- 7-15 working days

Parameters of Kerui Ceramic Fiber Mat for Sale

| Item | Common Type | Standard Type | High Purity Type | High Alumina Type | Zirconium Containing Type |

|---|---|---|---|---|---|

| Classification Temperature, ℃ | 1050 | 1260 | 1260 | 1350 | 1430 |

| Service Temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Bulk & Density, kg/m³ | 96-128 | 96-128 | 96-128 | 128-160 | 128-160 |

| Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) | -3 (1250℃) | -3 (1350℃) |

| Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) 0.22 (1000℃) | 0.132 (600℃) 0.22 (1000℃) | 0.76 (800℃) 0.20 (1000℃) |

| Strength of Extension, Mpa | 0.08-0.12 | ||||

| Al2O3, % | 44 | 46 | 47-49 | 52-55 | 39-40 |

| Al2O3+SiO2, % | 96 | 97 | 99 | 99 | - |

| Al2O3+SiO2+ZrO2, % | - | - | - | - | 99 |

| ZrO2, % | - | - | - | - | 15~17 |

| Fe2O3, % | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

| Size, mm | Standard Size: 7200/3600*610/1220*6-60; Customized Sizes | ||||

Note: Asbestos Free.

Good Composition and Manufacturing of Kerui Ceramic Fiber Insulation Mat

The primary constituent of ceramic fiber insulation mats is alumina-silica (Al₂O₃-SiO₂) ceramic fibers. These fibers are produced through various methods, including melt spinning or blowing of molten alumina and silica. The resulting fibers possess a high aspect ratio (length to diameter), contributing to the mat’s low thermal conductivity and excellent handling characteristics.

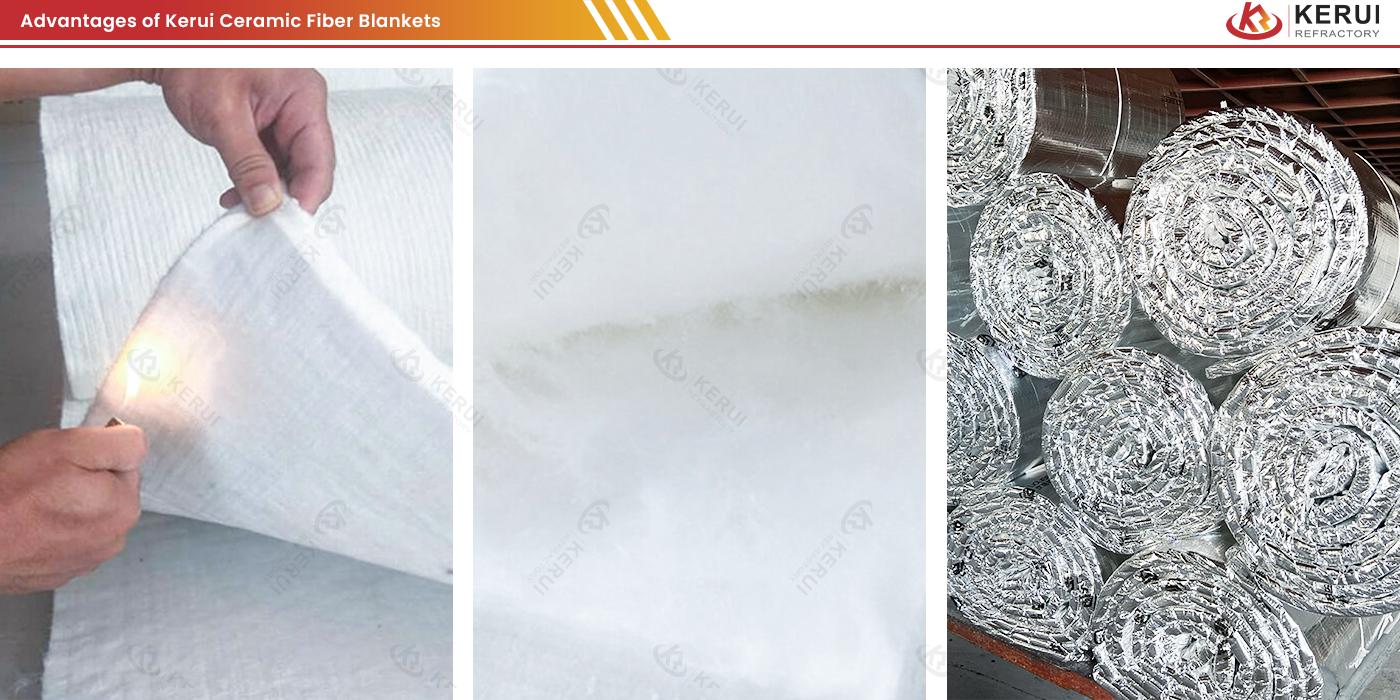

Key Features of Ceramic Fiber Mat

Porous, fine fiber structure traps air, which resists heat flow.

Results in energy savings and efficient temperature control.

This product prevents shrinkage, outgassing, and degradation at high heat.

It can handle rapid temperature changes without damage.

Fits complex shapes and irregular surfaces well.

Low density makes insulation lighter and easier to install.

Prevents outgassing and keeps insulation pure at high temperatures.

Resistant to most chemicals except strong alkalis, hydrofluoric acid, etc.

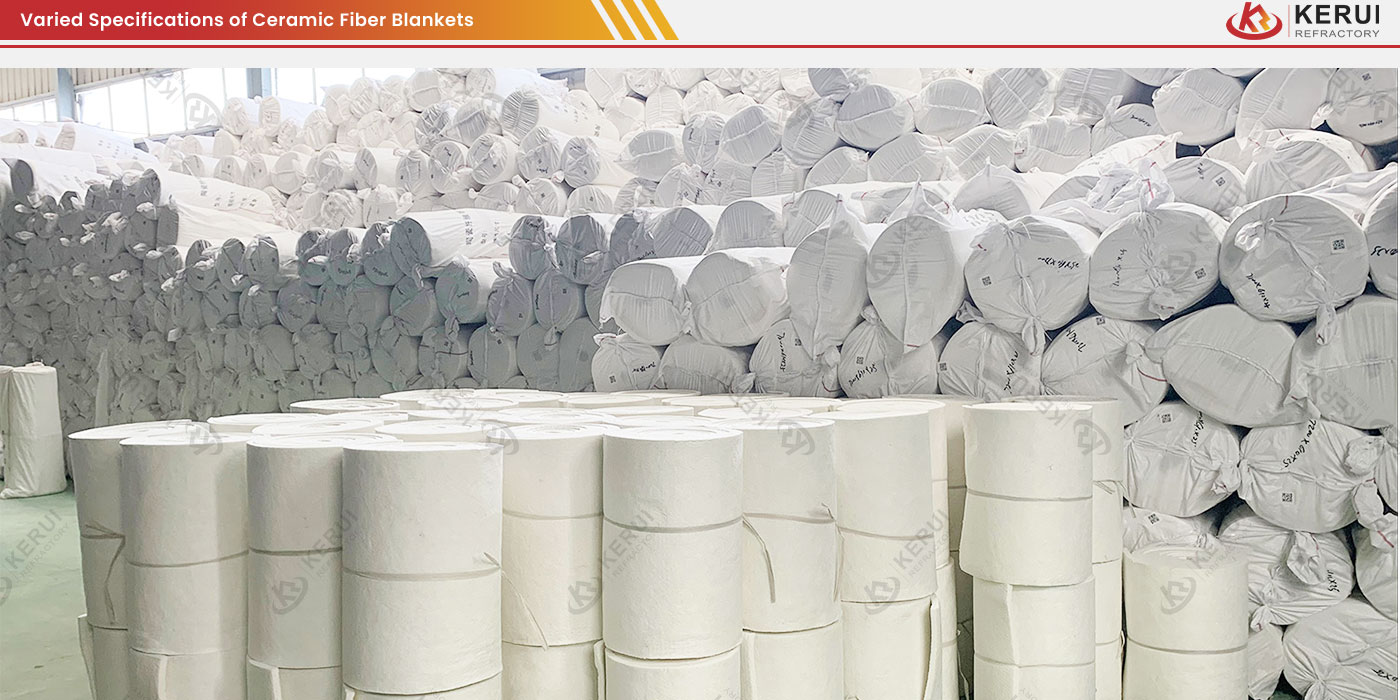

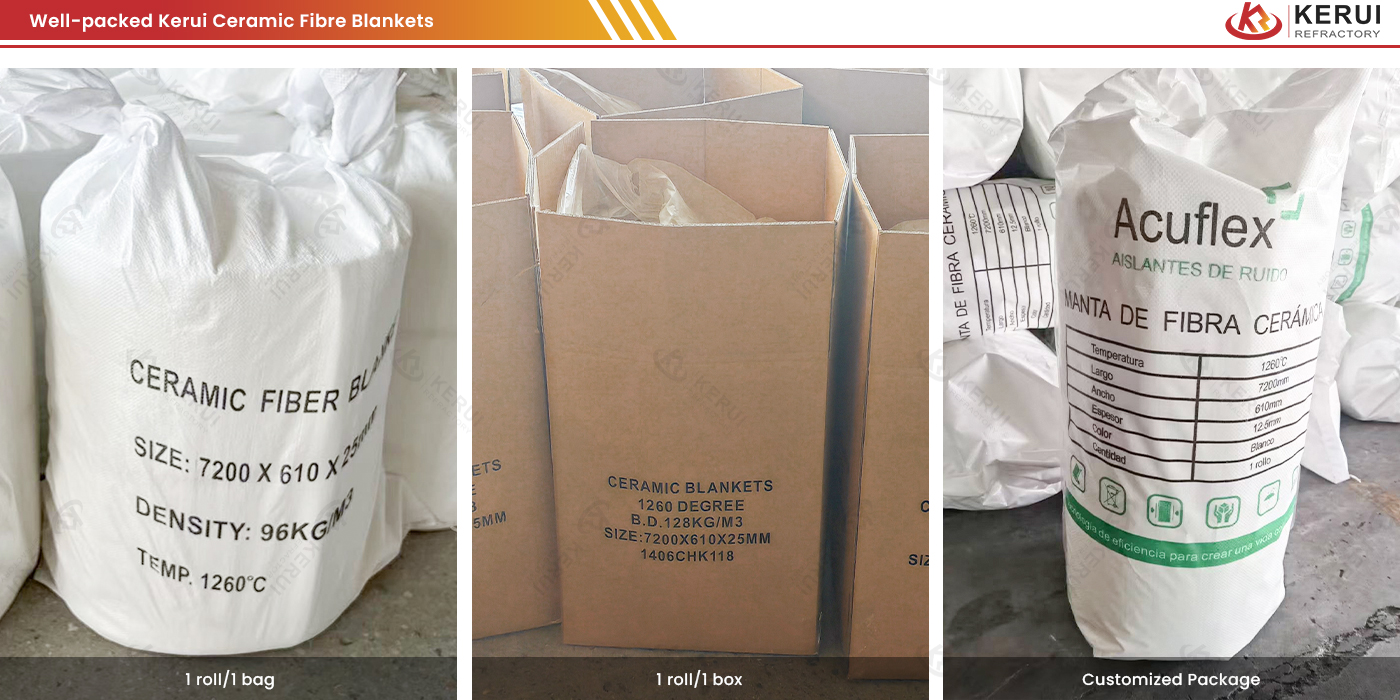

Well-packed Kerui Ceramic Fibre Mats

Kerui offers a variety of packaging options to meet diverse customer needs, including standard packaging as well as customized packaging services tailored to specific requirements.

Whether you need special sizes, protective materials, branding, or shipment-ready solutions, Kerui’s flexible packaging options ensure that the ceramic fiber products are securely packed, easy to handle, and optimized for transportation and storage.

- Packaging: 1 roll/1 bag; 2 rolls/1 bag; 1 roll/1 box;

- Price: Low factory price; Confirming shipping fees later;

Typical Applications of Kerui Ceramic Fiber Mat

The unique properties of ceramic fiber insulation mats make them suitable for a wide array of demanding applications across various industries, including:

- Industrial Furnaces and Kilns: Lining for heat treatment furnaces, ceramic kilns, glass melting furnaces, and other high-temperature processing equipment to minimize heat loss and improve energy efficiency.

- Boilers and HRSGs (Heat Recovery Steam Generators): Insulation for boiler walls, ducts, and exhaust systems to reduce heat loss and improve operational efficiency.

- Petrochemical Processing: This ceramic fiber wool is insulation for reactors, reformers, and other high-temperature vessels and piping.

- Power Generation: Insulation for turbines, exhaust ducts, and other high-temperature components in power plants.

Good Reviews on Kerui Ceramic Insulation Mats

Kerui ceramic fiber mats have received consistently positive reviews from customers across various industries. These glowing reviews affirm Kerui Ceramic Fiber Blanket as a top choice for those seeking dependable, high-performance thermal insulation solutions..

Kerui is Your Ceramic Fiber Insulation Mat Supplier

Ceramic fiber mats manufactured by Kerui are a critical component in modern thermal management. They offer a superior combination of high-temperature resistance, low thermal conductivity, lightweight nature, and flexibility.

As a leading manufacturer, Kerui’s rigorous quality control and innovative manufacturing processes ensure mats with exceptional thermal stability, durability, and purity. This commitment to excellence enables Kerui to deliver customized solutions that meet the specific needs of diverse industrial applications. View some videos on Kerui YouTube.