Magnesia spinel brick is a new type of basic refractory material. This type of brick is mainly composed of magnesium oxide and aluminum oxide. It has high refractoriness and is suitable for harsh environments. Kerui is the manufacturer. We offer factory prices, various brick types, and customized services.

- MgO: ≥80%;

- Al2O3: ≥3-10%;

- Bulk density: ≥2.9g/cm3;

- Apparent Porosity: ≤17%;

- Standard size: 230*114*65mm (standard)/And other sizes;

Types of Kerui Magnesia Spinel Bricks

Kerui magnesite spinel bricks are mainly divided into two types: Magnesia alumina spinel bricks and magnesia iron spinel bricks. Let’s take a look at the parameters of these two types of refractory bricks.

| Property | Magnesia Alumina Spinel Bricks | Magnesia Iron Spinel Bricks |

|---|---|---|

| Refractoriness | ★★★★★ | ★★★★☆ |

| Thermal Shock Resistance | ★★★★★ | ★★★★☆ |

| Slag Resistance | ★★★★☆ | ★★★★★ |

| Oxidation Resistance | ★★★★☆ | ★★★★★ |

| Thermal Conductivity | ★★★★★ | ★★★★★ |

| Volume Stability | ★★★★★ | ★★★★★ |

| Mechanical Strength | ★★★★★ | ★★★★☆ |

| Cost-Effectiveness | ★★★★☆ | ★★★★★ |

| Spalling Resistance | ★★★★☆ | ★★★★★ |

| Application Versatility | ★★★★★ | ★★★★☆ |

| Primary Application | Cement rotary kiln transition zones and other areas with significant thermal stress but relatively mild chemical erosion. | Cement rotary kiln burning zones, where its ability to form a protective coating and safeguard the kiln shell is highly valued. |

Type 1. Kerui Magnesia Alumina Spinel Brick for Sale

| Item | Index | |

|---|---|---|

| MgO, % | ≥ | 80 |

| Al2O3, % | ≥ | 10 |

| Apparent Porosity, % | ≤ | 17 |

| Bulk Density, g/cm³ | ≥ | 2.9 |

| Cold Crushing Strength, MPa | ≥ | 50 |

| High-temperature Bending Strength (1350℃*0.5h), MPa | ≥ | 3.5 |

| Thermal Shock Resistances (1100℃, Water Cooling), Cycle | ≥ | 12 |

Type 2. Kerui Magnesia Iron Spinel Brick for Sale

| Item | MFe-85A | MFe-85B | |

|---|---|---|---|

| MgO, % | ≥ | 85 | 85 |

| Al2O3, % | ≥ | 3-5 | 3-5 |

| Fe2O3, % | ≥ | 4-6 | 4-6 |

| Bulk Density, g/cm³ | ≥ | 2.95 | 2.90 |

| Cold Crushing Strength, MPa | ≥ | 55 | 50 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1650 | 1600 |

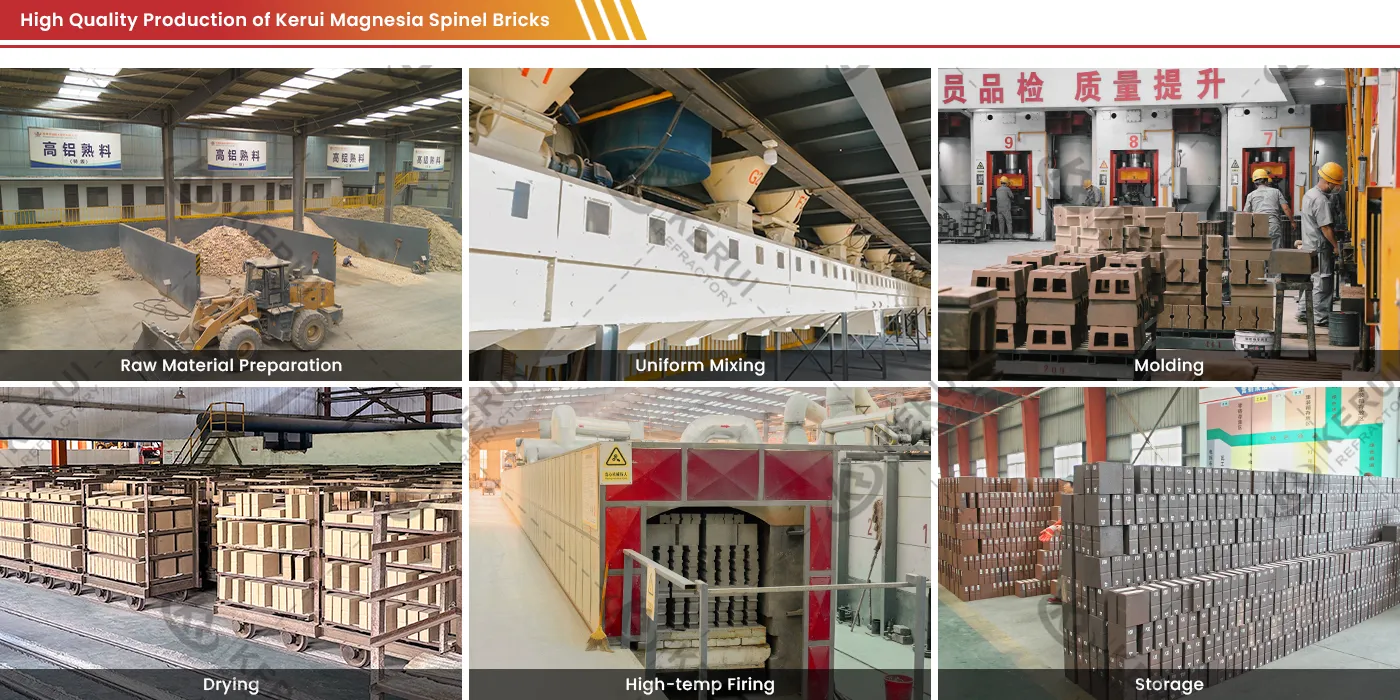

High-Quality Quality Control for Kerui Magnesia Spinel Refractory Bricks

- High-purity Raw Materials: Kerui uses High-purity, well-sintered magnesia and aluminum oxide (Al₂O₃)/bauxite chamotte for production.

- Fully automated mixing: Fully automated equipment mixes raw materials evenly according to precise proportions.

- Advanced Firing Process: An automated temperature control system in the factory ensures the production of high-quality, highly dense bricks.

- Precise Dimensions: Kerui’s pressing and grinding processes ensure that the final products meet standard specifications.

- Professional Reports: Kerui Refractory can provide third-party reports on composition and other details based on customer requirements.

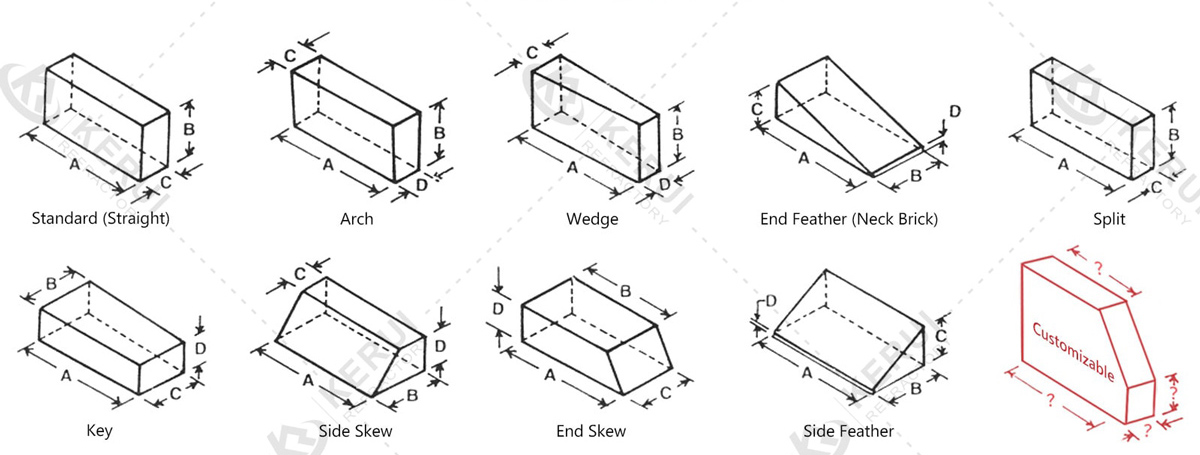

Selecting the Suitable Size of Spinel Fire Brick

Kerui offers standard sizes and shapes. The standard size is 230*114*65mm. In addition, thicker sizes are also available in stock.

The standard shapes include straight, curved, axe-shaped, wedge-shaped, arch bricks, and so on. Moreover, Kerui provides customized special-shaped bricks. We can customize brick shapes based on your drawings.

Additionally, we supply brick types commonly used in cement kilns and other high-temperature furnaces, including B320, B425, B620, B622, B322, BP22, BP+20, BP+22, B825, PB250, PB251, etc.

Different Color of Kerui Spinel Refractory Bricks Are Applied Worldwide

Two core elements are responsible for the color differences in magnesia spinel bricks:

Iron Content

- High Fe₂O₃ content causes a brown/tan color.

- Very low Fe₂O₃ content (usually <0.5%) results in white/light yellow/gray-white bricks. This uses high-purity fused magnesia and industrial alumina as raw materials.

Redox Atmosphere

- In areas with sufficient oxygen (oxidizing atmosphere), iron exists as Fe³⁺ (ferric iron), showing a brownish-red or dark brown color.

- In areas with insufficient oxygen (reducing atmosphere), iron changes to Fe²⁺ (ferrous iron), with a color more bluish or gray-black.

Kerui Spinel Refractory Bricks Are Applied Worldwide

Up to now, Kerui has shipped magnesia-spinel bricks to countries such as South Korea, Egypt, Russia, Saudi Arabia, Turkey, etc. Customers have been highly satisfied with our products and continue to collaborate with us for long-term partnerships and mutual success. Together, we tackle the challenges of high-temperature industries.

Applications of Spinel Fire Bricks

| Primary Application Industries | Typical Application Areas |

|---|---|

| Cement Industry | Transition zone of cement rotary kilns |

| Steel & Metallurgy | Ladle walls and bottoms, secondary refining furnaces |

| Glass Industry | Glass furnaces, regenerators of glass kilns |

| Non-ferrous Metallurgy | Copper smelting furnaces and other non-ferrous metal smelting equipment |

| Other High-Temperature Kilns | Lime kilns (burnt lime linings) |

Kerui is Your Magnesia Spinel Brick Manufacturer and Supplier

- Direct Production Factory;

- Comprehensive Technical Support;

- Overall Supporting Product Packaging Solution;

- Customized Packaging;

- Optimal Transportation Routes;

- High Product and Service Satisfaction;

- After-Sales Technical Support and Construction Guidance;

- Industrial Certificates and International Certificates;

Note: View more videos about Kerui on Youtube.

FAQs about Magnesia Spinel Bricks

How to Store and Use Magnesia Spinel Bricks?

What Industries Are Magnesia Iron Spinel Bricks Mainly Used In?