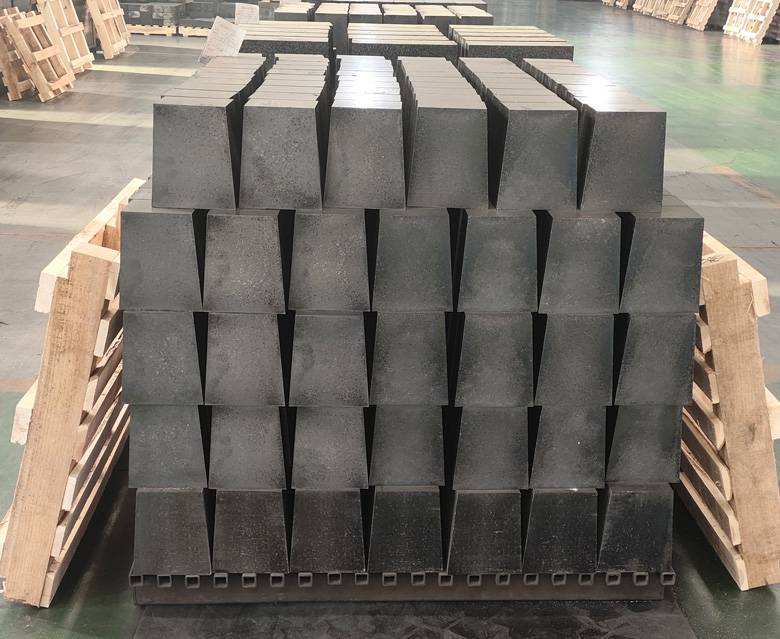

Basic refractory bricks refers to alkaline refractory bricks. As a manufacturer, Kerui provides a wide range of high-quality bricks. These refractory bricks offer stable performance and a long service life in high-temperature applications.

- Working Temperature: 500-1800ºC;

- Bulk Density: 1.9-4.05g/cm³;

- Cold Crushing Strength: ≥30-100MPa;

- Size: 230*114*65mm (standard)/And other sizes;

Different Types of Basic Refractory Bricks

Basic refractory bricks primarily consist of a series of magnesia-based bricks. These bricks are manufactured using high-quality magnesia, limestone, and other premium refractory materials. See details.

High Quality Control of Basic Fire Bricks

- Precise Proportioning of Raw Materials;

- Uniform Compression with a 60-Ton Press;

- Firing in Two 168-Meter High-Temperature Tunnel Kilns for Stable Quality;

- High Brick Yield Rate;

- Professional Inspection Report According to Customers’ Need.

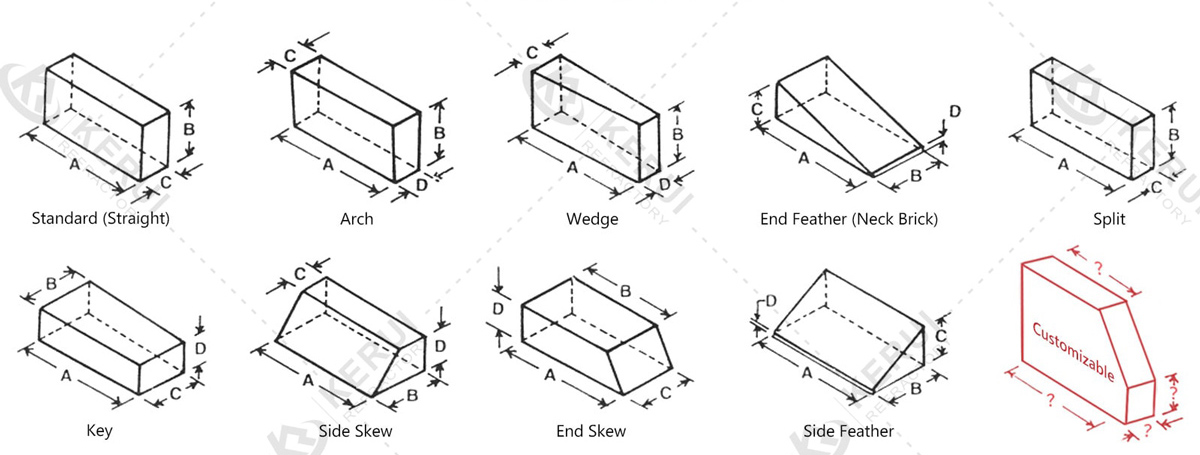

Get Suitable Shapes of Basic Fire Bricks

Kerui offers standard straight bricks, thickened bricks, wedge-shaped bricks, arc-shaped bricks, lattice bricks, anchor bricks, steel-flow bricks, and lining bricks, and others. These refractory brick types can meet customers’ regular needs.

In addition, to meet special requirements, Kerui also provides customized shaped bricks. Please send us your detailed specifications and drawings.

Features of Kerui Basic Bricks

- High refractoriness;

- Strong resistance to alkaline slag;

- Good thermal shock stability;

- Good hydration resistance;

- Good oxidation resistance;

Elegant Packaging and Fast Delivery

- Ready-to-ship inventory ensures delivery within 15-30 days;

- Custom products are quickly confirmed based on drawings;

- Complete fumigated pallet packaging or customized packaging options;

- Optimal shipping solutions recommended based on customers’ requirements for freight cost and delivery time.

Basic Fire Refractory Bricks in Industry

Refractory fire bricks for sale are mainly used for furnace linings, furnace bottoms, furnace openings, and furnace walls.

- Steel Industry: Basic oxygen furnaces, electric arc furnaces, etc.

- Non-Ferrous Metal Smelting: Copper and nickel smelting furnaces, etc.

- Glass Industry: Glass melting kilns, etc.

- Cement Industry: Cement rotary kilns, etc.

- Chemical Industry: High-temperature chemical reactors, etc.

- Ceramics Industry: Ceramic kilns, etc.

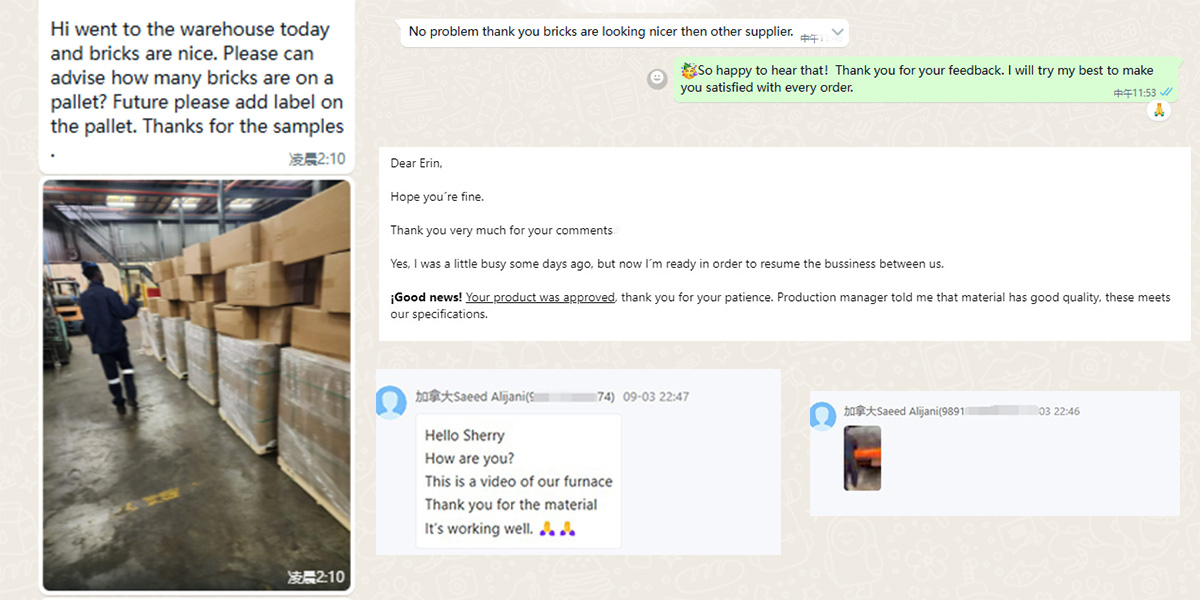

Kerui Basic Refractory Bricks Exported to 50 Countries

Kerui basic lining refractory bricks are Exported to Over 50 Countries Worldwide, Including Turkey, Indonesia, Brazil, Belarus, South Africa, the Philippines, Saudi Arabia, and so on.

Great Feedback from Kerui Partners

Choose Kerui as Your Partner!

- OEM: Kerui has a factory covered 50,000 square meter and offers factory price. See the introduction on Linkedin;

- Technical Support: Technicians with over 20-years experience in multiple industries;

- Full Range of Supporting Products: Kerui offers wide range of bricks and matching products;

- Certification: ISO 9001, ISO 14001, CE, patents, etc.

- Customized Services: The customization of bricks or packaging is available;

- 70% Customer Repurchase: 70% customers purchase Kerui products again or multiple times.