Alumina fire brick is a type of refractory brick with an alumina content of more than 25-99%. This kind of brick has the characteristics of high hardness and high refractoriness. Accordingly, many high-temperature kilns use this kind of fire brick to extend the service life of the kiln. Kerui Refractory offers a large number of in-stock and competitive factory prices.

- Al2O3: ≥25-99%;

- Bulk Density: 1.90-3.95 g/cm³;

- Refractoriness Under Load: 1250-1790ºC;

- Cold Crushing Strength: 15-100MPa;

Kinds of Kerui Alumina Fire Bricks

Based on the varying alumina content, Kerui Refractory primarily offers the following types of standard bricks to our partners. In addition to our standard refractory brick, Kerui Refractory is also committed to catering to our partners’ unique requirements. For example, we provide customized brick solutions.

Description of Alumina Bricks

In general, alumina bricks composition is bauxite, clay, and other raw materials. It is a high-temperature resistant brick. Among components, one of their main components is alumina. It has a melting point of 2050°C (3722°F). So, aluminum fire bricks have a refractoriness of over 1750°C (3182°F). So, this feature enables them to withstand extreme temperatures.

Characteristics of Kerui Aluminum Bricks

- High-temperature resistance: Alumina firebricks surpass clay bricks in terms of refractoriness. Therefore, partners can use aluminum bricks instead of clay bricks when working conditions demand high temperatures.

- Chemically stable structure: Neutral refractories like high alumina bricks exhibit a degree of resistance to acidic and alkaline corrosive substances. And alkaline refractories like AZS bricks can maintain structural stability for extended periods in strongly alkaline corrosive environments. In addition, acid-resistant refractories like fireclay brick remain unaffected in highly acidic and corrosive environments.

- Excellent thermal shock resistance: Alumina lining bricks retain structural integrity under rapid temperature fluctuations. So, this feature prevents cracking or spalling.

- High strength: The brick of aluminum can withstand demanding mechanical environments. Therefore, it is capable of bearing mechanical loads and exhibiting abrasion resistance.

- High density: Their density ranges between 1.90-3.95 g/cm³. In brief, this imparts them with substantial weight and low porosity.

- Low iron content: Iron content influences the performance of fire bricks. Generally, it affects properties like refractoriness, slag resistance, thermal conductivity, and so on. The final low iron content enhances these properties.

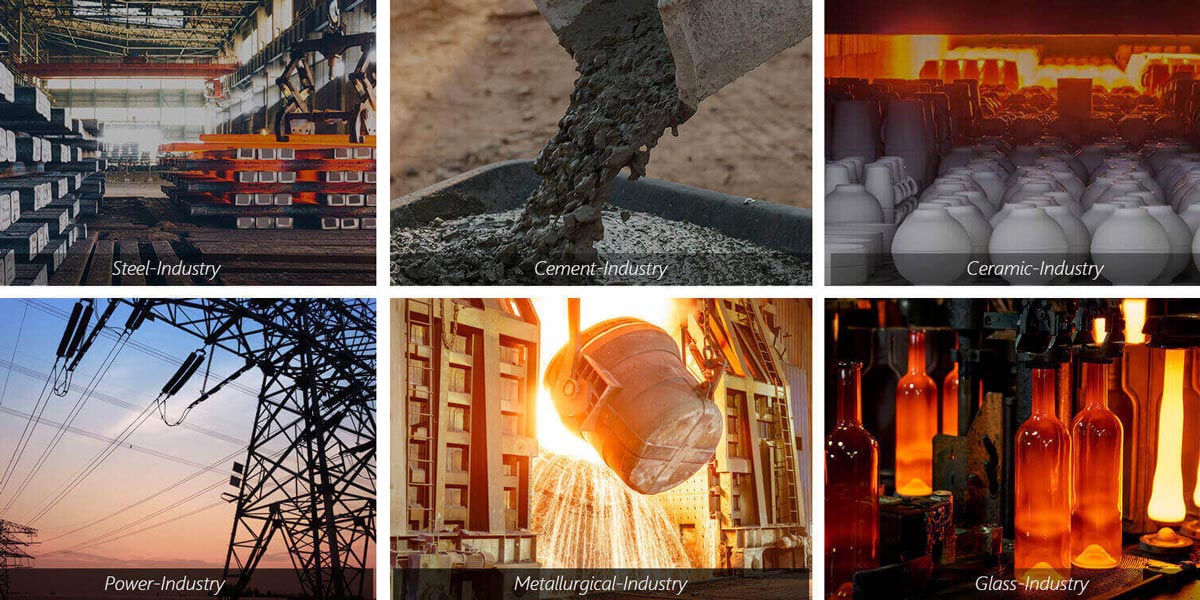

Kerui Alumina Fire Brick Uses

High-temperature Zones in High-temperature Kilns:

- Steel industry: For example, blast furnaces, hot blast stoves, electric arc furnaces, converters, etc.

- Construction materials industry: cement kilns, glass kilns, ceramic kilns, rotary kiln lines, etc.

- Chemical industry: For example, reactors, synthesis furnaces, cracking furnaces, etc.

- Power industry: Boilers, waste incinerators, desulfurization equipment, etc.

- Non-ferrous metals industry: For example, smelting furnaces, aluminum electrolytic cells, etc.

Other Applications:

- In addition, aluminum bricks offer exceptional high-temperature resistance solutions for these critical high-temperature parts, for example, chimneys, pipes, burners, fireboxes, etc.

Kerui Refractory is Your Ideal Alumina Bricks Manufacturer

When seeking a reliable manufacturer of high-alumina refractory materials, Kerui Refractory stands out as a trusted partner. Moreover, we offer a comprehensive range of services and products to cater to your specific needs:

- First, competitive ex-factory alumina bricks prices;

- Second, superior quality aluminum bricks with quality inspection reports;

- Third, customized alumina refractory bricks (grade, shape, size, and other parameters);

- Fourth, aluminum brick solutions and high-temperature kiln solutions;

- Fifth, prompt delivery and direct ex-stock shipment options;

- Finally, after-sales installation guidance.

Contact Kerui Refractory Now

In summary, contact Kerui Refractory now to discuss your specific requirements. Kerui Refractory is always your trusted partner. And certainly, we help you to achieve optimal performance and cost-efficiency in your high-temperature applications. In addition, partners can follow Kerui Youtube to see some videos.