Monolithic refractory products are mainly divided into refractory cement, refractory castable, ramming mass, and refractory mortar. These unshaped refractory materials are resistant to high temperatures and highly mouldable. They are widely used in high temperature industries and industrial construction, like steel metallurgy, and other industries. Kerui Refractory offers the standard and customized products, one stop service and construction services.

Refractory Cement

Kerui refractory cement is a mixture of refractory materials (aluminum dioxide) and special additives. It possesses high temperature resistance and fire resistance characteristics. It can be mixed and configured with various refractory raw materials to create various unshaped refractory materials. Kerui Refractory mainly offers three types of refractory cement.

Refractory Castable

Kerui refractory castable is composed of refractory cement, refractory aggregates, binders, and additives. It is a refractory material that exhibits good flowability after adding water. Common construction methods include vibration casting, pumping casting, ramming, and spraying.

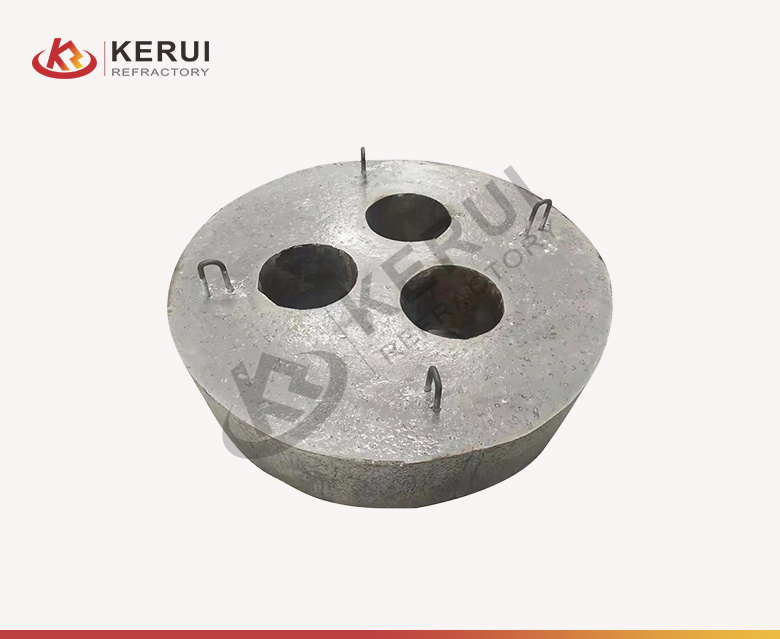

Ramming Mass

Kerui refractory ramming mass is a mixture of various refractory powders and binders. It has a low porosity and high density. Ramming material is constructed using forced ramming. It has a refractoriness of up to 1800 degrees Celsius. And it is suitable for various high-temperature kilns.

Refractory Mortar

Kerui refractory mortar is mainly made of refractory cement and refractory aggregates. It has the characteristics of withstanding high temperatures and chemical erosion. Its load softening temperature ranges from 1320 to 1600 degrees Celsius. Typically, it is used in conjunction with other refractory materials.

Customized Monolithic Refractories

Due to the fact that standard products may not always meet customers’ performance requirements, Kerui Refractory Group offers customized unshaped refractory products to cater to the specific needs of various industries.

Submit Requirements

The high load softening temperature of silicon brick reaches 1640-1670ºC. The stability of volume change ensures that it maintains its structural integrity and performance under extremely high-temperature conditions.

Confirm Requirements

Our technical and production teams will conduct technical and production assessments of the customer’s requirements. Once the requirements are met, we will promptly arrange for production. Kerui Refractory factory has an annual production capacity of 250,000 tons. This ensures short production and delivery cycles.

Advantages of Moldable Refractory Products

Corrosion Resistance

Kerui monolithic refractory materials have strong corrosion resistance. At high temperatures, they do not react with corrosive substances. They can maintain their structural stability and strength. This feature helps extend the lifespan of equipment.

High Temperature Resistance

Kerui monolithic refractories can withstand temperatures ranging from 1300 to 1800 degrees Celsius. They can be used in high-temperature environments while maintaining their structural integrity. Importantly, they exhibit strong thermal shock resistance, as rapid temperature changes do not affect their performance.

Easy Installation

Monolithicd refractory products are easier and quicker to transport and install. These products do not have seams during installation. This feature makes it convenient for both installation and subsequent maintenance. They help businesses save on installation time and maintenance costs.

Wear Resistance

Kerui monolithic refractory materials have excellent wear resistance. They can withstand repeated abrasion and friction while maintaining structural integrity. It effectively extends the lifespan of equipment.

Application Industries of Monolithic Refractory Materials

Steel Metallurgy

Kerui refractories and monolithics products are environmentally friendly and heat-resistant. They are commonly used in blast furnaces, hot blast stoves, heating furnaces, electric furnaces, metallurgical furnaces, high-temperature reaction furnaces, electrolytic cells, ladles, oxidizing converters, rotary kilns, and so on.

Nonferrous Metal Smelting

The nonferrous metal smelting industry has high requirements for temperature, corrosion resistance, and environmental protection. In this industry, Kerui amorphous refractory materials can provide protection and production efficiency for kilns. Typically, they are used in nonferrous metal smelting furnaces, and so on.

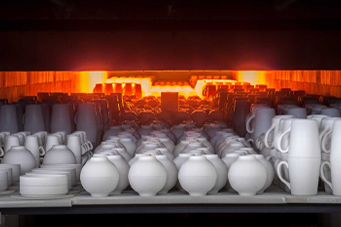

Building Materials

The building materials industry has very high requirements for sealing and performance. Kerui amorphous refractory materials can meet different requirements. They are commonly used in ceramic kilns, glass kilns, lime kilns, cement kilns, calcining kilns, annealing furnaces, arc furnaces, heat storage chambers, and so on.

Energy and Environmental Protection

The energy and environmental protection industry has certain requirements for refractory and insulation. Kerui provides customized monolithic refractory linings to meet customer performance requirements. They are used in pyrolysis furnaces, decompression furnaces, boilers, waste incinerators, heat treatment kilns, and so on.

Global Cases of Monolithic Refractory Products

Kerui’s partners are in 50+ countries, including South Korea, Vietnam, Indonesia, the Philippines, Pakistan, Saudi Arabia, Kuwait, Turkey, Bahrain, the United Arab Emirates, Uzbekistan, Kazakhstan, Kyrgyzstan, and other countries. View the global cases in detail.

We provide these customers with standard products, customized products, fireproof and insulation solutions, as well as after-sales service. These customers have a high level of satisfaction with our products and services. When these customers reorder, they decisively choose Kerui Refractory. Choosing Kerui Refractory means choosing quality.

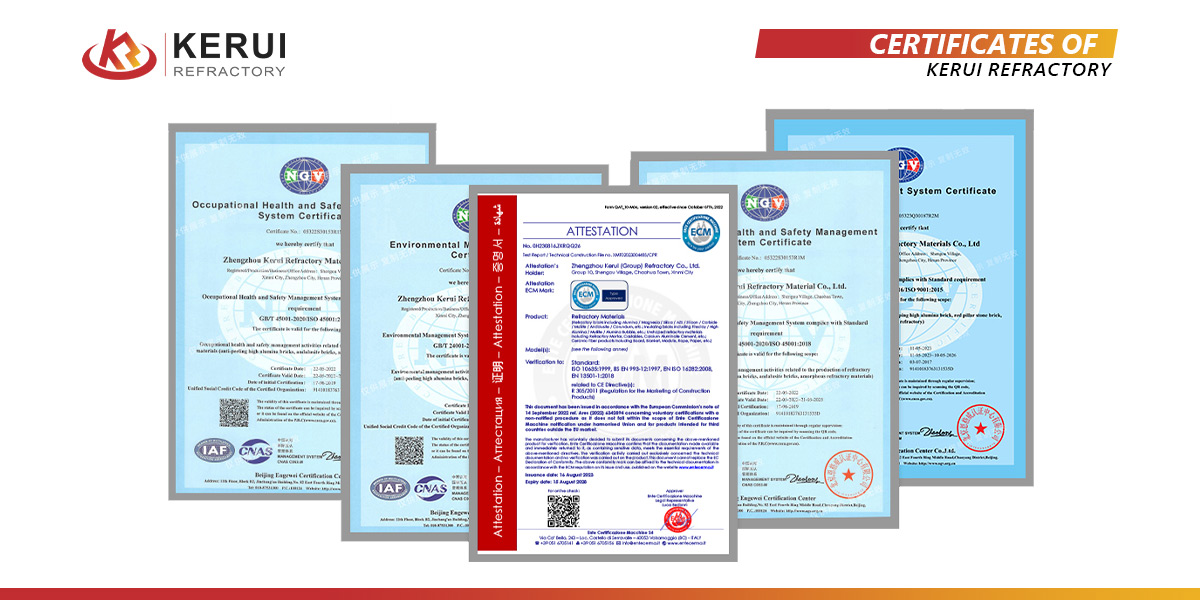

Cooperate with Monolithic Refractory Products Manufacturer – Kerui Refractory

- Technical guidance provided by over 20 technical personnel

- The design of overall solutions for furnace refractories and insulation

- Fully digitalized management of production workshops

- Customized monolithic refractory products

- Complete product quality traceability system and production management system

- One-on-one professional consultation services

- Fast delivery and professional packaging service

- Construction guidance services

Contact Us Right Now!

Kerui Refractory offers a variety of standard and customized monolithic refractory products. Based on the customer’s usage scenarios and performance requirements, we provide detailed refractory innovative design solutions, including every detail. Whether you need materials for kilns, furnace linings, or other industrial equipment, we have the professional expertise and products to provide you with a one-stop solution. Our engineers and technical team also ensure that construction meets the highest quality standards. Choose us as your trusted partner to meet all your refractory material needs. Follow Kerui Facebook to see more news.