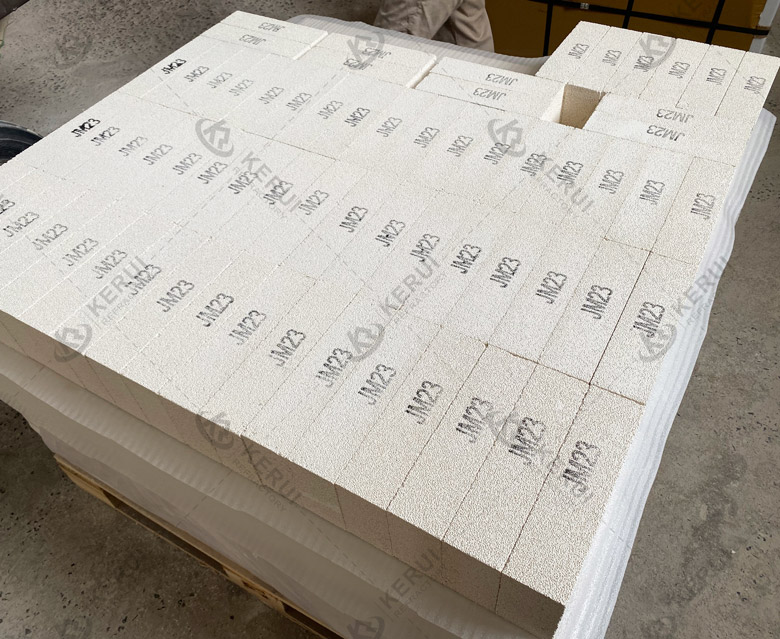

JM23 Insulation Brick

JM23 insulation brick is premium lightweight refractory material, renowned for its exceptional thermal stability and low thermal conductivity. It helps to cut heat loss by 20-40% and save fuel cost. As a leading manufacturer and global supplier, Kerui Refractory provides customized brick, tailored packaging, end-to-end refractory solutions.

.

- Free Sample:

- Available

- Document:

- Certificates Supporting

- Performance Test:

- Support

- Shipment:

- 7-35 working days

Insulating Firebrick J23 for Sale

- Hot Size: standard bricks 230*114*65mm; In addition, we provide thickened bricks (230*114*76mm), 250x124x65mm, wedge-shaped bricks, etc.

- Customized Size: Factories with strong production capacity can support customized insulation brick types according to customer drawings and sizes.

- Hot Packaging: Protection pads between each layer of bricks; Plastic film on the top and bottom; The outermost wooden fumigation pallet;

- Customized Packaging: The packaging material and logo can be customized according to customer needs;

- Loading: 680 standard bricks/pallet; 20 pallets/20′ container;

- Delivery: 7-30 days for spot stock and 15-35 days for customized products.

Parameter of JM23 Bricks

| Item/Grade | JM-23 | |||

|---|---|---|---|---|

| Type | A | B | C | D |

| Al2O3, % | ≥42 | ≥42 | ≥45 | ≥48 |

| Fe2O3, % | ≤1.2 | ≤1.2 | ≤1.0 | ≤1.0 |

| Bulk Density, g/cm³ | 0.55 | 0.6 | 0.8 | 1.00 |

| Reheating Linear Change, % | ≤-0.5 | ≤-0.55 | ≤-0.4 | ≤-0.3 |

| Temperature*12h | 1230℃ | 1260℃ | 1300℃ | 1300℃ |

| Cold Crushing Strength, MPa | ≥1.2 | ≥1.5 | ≥2.3 | ≥3 |

| Thermal Conductivity 350℃, W/(m·K) | 0.17 | 0.19 | 0.24 | 0.31 |

Control JM23 Bricks Quality at Every Step

High-purity Raw Materials

Use ≥75% high-purity mullite aggregate, Al₂O₃ content is stable at 45-50%, and impurities (Fe₂O₃, etc.) are controlled at <0.5%.

Batch Testing

Each batch of raw materials undergoes analysis + particle size distribution test to ensure that the chemical composition and particle grading meet the standards.

Precise Batching

Digital batching system accurate and fast batching. Its error <0.3%, to avoid performance fluctuations.

High-pressure Molding and High-temperature SinteringUse 400-1100 ton hydraulic press, green body density deviation ≤1.5%. 3 tunnel kilns 17000°C constant temperature sintering, temperature control accuracy ±5°C, to ensure the stability of the crystal structure.

International Certification

ISO 9001 quality management system + SGS third-party test report.

Sample Inspection

Sampling inspection of finished products, including physical properties, thermal conductivity, compressive strength, thermal shock stability, etc.

Shockproof Packaging

EPE pearl cotton + wooden box, breakage rate <0.1%.

Moisture Content Control

Dry to ≤0.3% before leaving the factory to avoid moisture absorption during transportation.

Features of Kerui JM23 Insulation Refractory Bricks

JM23 insulation bricks are made from high-quality high-alumina bauxite clinker as the primary raw material, with a porous structure formed by foaming or chemical methods. They are then fired at high temperatures to create high-quality insulation refractory bricks.

- Thermal Insulation: With a high porosity, these bricks offer excellent thermal insulation performance.

- Good Thermal Stability: The material remains stable in both high and low-temperature environments. This makes it resistant to deformation or damage.

- Low Thermal Conductivity: The JM23 insulation brick effectively conducts heat to improve energy utilization efficiency. It saves more than 30% energy than traditional refractory bricks.

- High Temperature Resistance: Resistant to 1260℃. Keep strong structural stability at high temperatures.

- Lightweight: The material has a low density to make the bricks lightweight, easy to transport and install, and to reduce the furnace structural load.

- Precise Size with Small Tolerance: It can be cut and processed to reduce the amount of mortar and refractory mud.

- Low Impurity Content: Resistant to reducing atmosphere and acid and alkali corrosion, suitable for corrosive environments such as petrochemical cracking furnaces.

Kerui Insulating Soft Fire Brick J23 Shipped Worldwide

Kerui has shipped JM23 insulation bricks to over 50 countries. We provide both standard and customized bricks based on the needs of our customers. Additionally, we offer recommendations tailored to the specific conditions of our customers’ furnaces and provide technical guidance during installation. Our customers gave good reviews on our insulating firebricks and services.

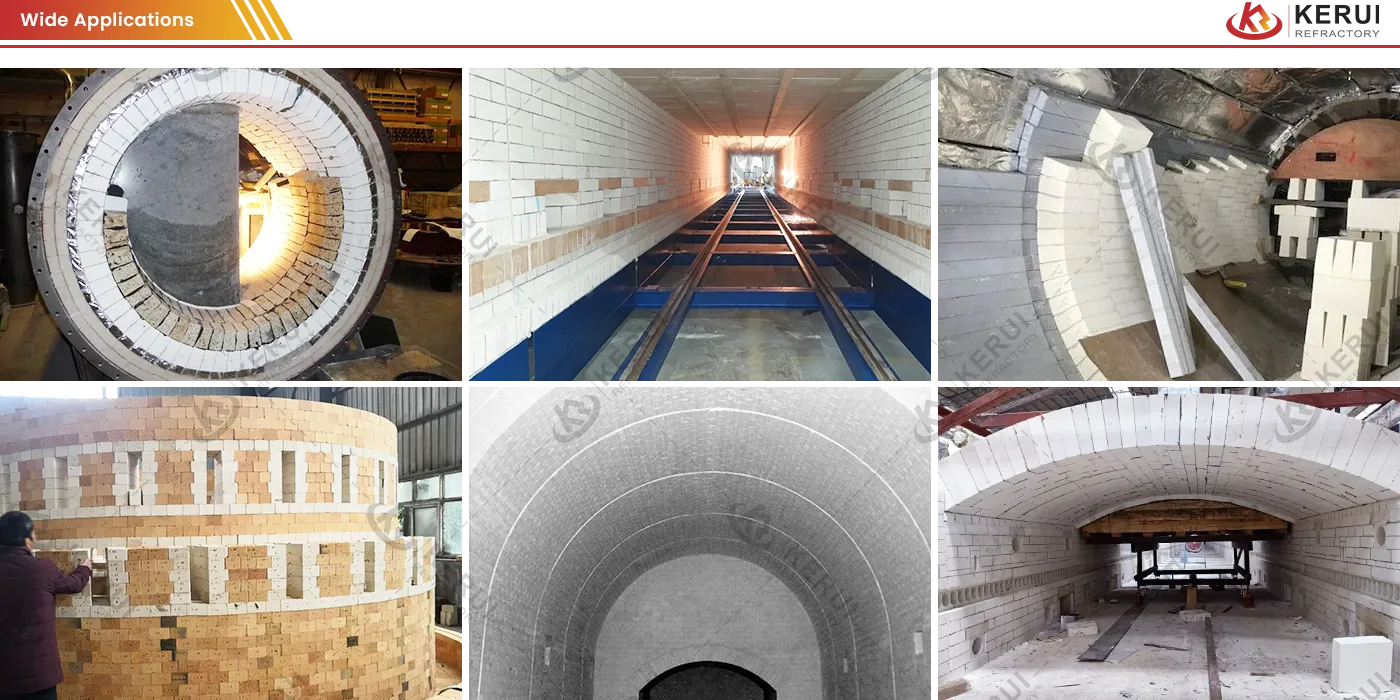

Industry and Furnace JM23 Bricks Applied in

The uses of 19 insulating firebrick j23 is primarily in the lining, insulation layer, and roof of industrial furnaces and other such components.

- Steel Industry: Hot blast stoves, heating furnaces, sintering furnaces, annealing furnaces, tempering furnaces, converter furnaces, steel ladle insulation linings, etc.

- Non-ferrous Metals Industry: Smelting furnaces, melting furnaces, reduction furnaces, roller hearth furnaces, tube heating furnaces, etc.

- Environmental Protection Industry: Waste incinerators, flue gas treatment furnaces, refinery heating furnaces, cracking furnaces, etc.

- Cement Industry: Cement rotary kilns, preheater towers, etc.

- Power Industry: Boilers, gas turbines, heat exchangers, etc.

- Ceramic Industry: Kilns, firing furnaces, push plate kilns, ceramic roller kilns, etc.

- Glass Industry: Glass tank furnaces, tunnel furnaces, etc.

JM Series Comparison

| Parameter | JM23 | JM26 | JM28 | JM30 |

| Classification Temp | 1230-1300°C | 1400°C | 1500°C | 1600°C |

| Bulk Density | 0.55–1.0g/cm³ | 0.7–1.0g/cm³ | 0.8–0.9g/cm³ | 1.0–1.1g/cm³ |

| Thermal Conductivity | 0.17–0.31W/m·K | 0.21–0.32W/m·K | 0.28–0.34W/m·K | 0.4–0.43W/m·K |

| Key Advantages | Lightest weight. Lowest thermal conductivity for optimal energy savings. |

Higher temperature resistance (1430°C). Moderate strength (1.4–1.6 MPa). Best cost-performance ratio. |

Withstands 1540°C, compressive strength for high-load environments. Excellent thermal shock resistance. |

Ultra-high temperature resistance (1650°C). Superior slag corrosion resistance. |

| Typical Applications | Ceramic roller kilns, petrochemical pipeline insulation (medium-low temp). | Steel industry hot blast stoves, glass kiln insulation layers. | Cement rotary kilns, ladle permanent linings. | Glass melting furnace crowns, metallurgical electrode furnaces. |

Contact Kerui Refractory

Kerui Refractory has more than 20 years of manufacturing and exporting refractory bricks. We have international certificates, patents of refractory bricks, and other certificates. We have strong production capacity and strict quality control system to guarantee the quality. Moreover, our professional manager and technical professionals will guide you to choose the suitable bricks and high-temperature construction. View some video on Kerui YouTube.