Magnesia spinel bricks are high-temperature refractory materials made from magnesia and spinel. They offer excellent thermal shock resistance, erosion resistance, and high-temperature strength. These bricks are widely used in high-temperature industrial kilns, such as cement kilns and glass kilns.

Introduction of Magnesia Spinel Bricks

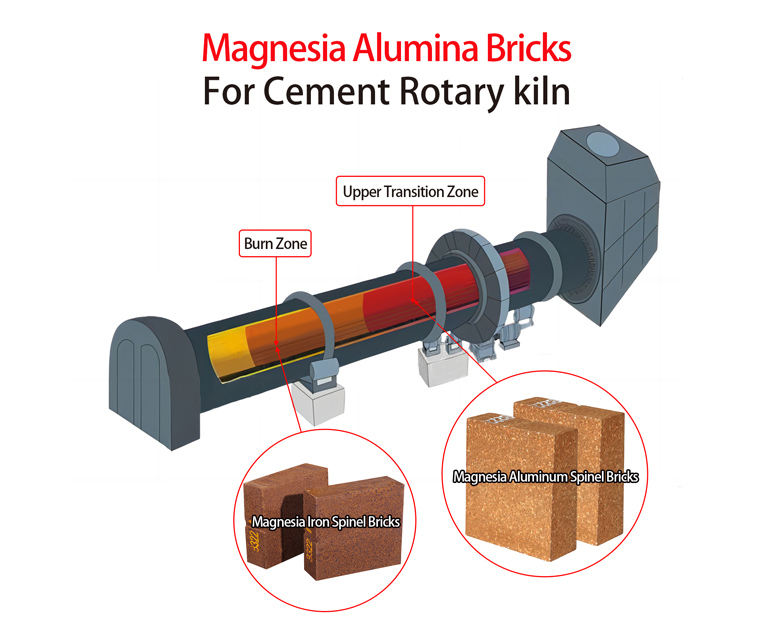

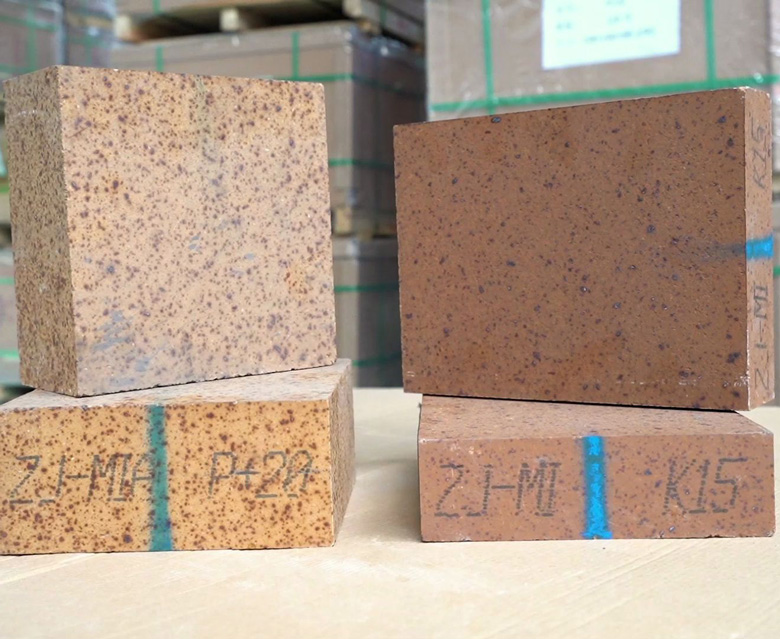

Currently, magnesia alumina spinel bricks and magnesia iron spinel bricks are the most commonly used types. Kerui Refractory is one of the few top manufacturers globally that can consistently produce high-quality magnesia spinel bricks. These bricks are widely applied across various industries. Below, we provide a detailed guide on how to store and use these bricks.

Storage Guidelines of Magnesia Spinel Bricks

- Environment: Store in a dry, well-ventilated indoor warehouse. Avoid direct sunlight and rain.

- Stacking Method: Stack by type and size. Keep the height below 1.5 meters to avoid heavy pressure and collisions.

- Moisture Protection: Use moisture-proof pads or plastic film to cover the bricks during rainy or humid seasons.

- Storage Duration: Do not store for more than one year to prevent moisture damage or performance loss.

Usage Guidelines of Magnesia Spinel Bricks

Preparation Before Installation:

- Inspect the magnesia spinel bricks and remove any damaged or cracked ones.

- Clean the installation surface to ensure it is flat, clean, and free of debris.

- Pre-arrange the bricks according to design requirements to ensure accurate dimensions.

Installation Requirements:

- Use refractory mortar that matches the brick material.

- Stagger the brick joints and keep the joint width between 1-2mm.

- Clean excess mortar during installation to ensure tight joints.

Baking Process:

- Follow the baking curve strictly to avoid cracking caused by rapid temperature rise.

- Monitor the process closely and address any issues immediately.

Comparison Between Magnesia-Alumina Spinel Bricks and Magnesia-Iron Spinel Bricks

| Feature | Magnesia-Alumina Spinel Bricks | Magnesia-Iron Spinel Bricks |

| Main Components | Magnesia, Bauxite | Magnesia, Iron Ore |

| Advantages | Excellent thermal shock resistance, strong alkali resistance, high high-temperature strength | Superior thermal shock resistance, strong slag resistance, lower cost |

| Disadvantages | Poor slag resistance, higher cost | Weak alkali resistance, slightly lower high-temperature strength |

| Applications | Cement kiln transition zone, glass kiln regenerators | Cement kiln burning zone, metallurgical furnaces |

- Magnesia alumina spinel Bricks: It has better thermal shock resistance and alkali resistance. This brick is ideal for high-temperature and strong alkali environments.

- Magnesia iron spinel bricks: It has superior thermal shock resistance and slag resistance. This brick is suitable for high-temperature and strong slag environments.

Conclusion

Kerui is a comprehensive group specializing in refractory material production, sales, technical solutions, and EPC project services. Our magnesia-iron spinel bricks and magnesia-alumina spinel bricks are known for their excellent and consistent quality, with exceptional resistance properties. They have received high praise from customers worldwide, including Canada and Singapore.

If you need magnesia alumina spinel bricks or magnesia iron spinel bricks, feel free to leave a message. We will contact you immediately to provide a detailed delivery plan. Additionally, we offer competitive factory prices and comprehensive after-sales services to ensure your complete satisfaction.