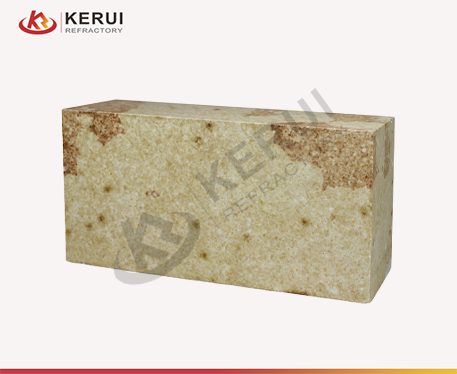

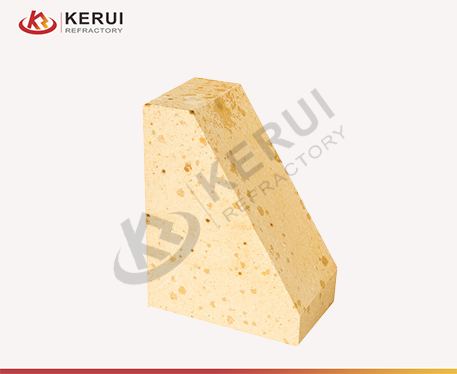

Fire bricks are specially formulated and manufactured bricks that can withstand repeated heating cycles at high temperatures. These bricks can be used in many high-temperature industries to maintain stable structures, such as steelmaking, metal smelting, building materials, and so on. Kerui Refractory offers standard firebricks (230*114*65mm). In addition, we can customize special-shaped bricks according to the requirements of our partners. Please send us the precise drawings.

Kinds of Kerui Fire Bricks

According to the composition, Kerui Refractory offers a variety of firebricks to meet the needs of our partners.

What is The Firebrick Refractory?

Industrial fire bricks are shaped bricks made of refractory materials that can be used in high-temperature corrosive environments. They are more resistant to high temperatures than ordinary bricks. They are generally made from refractory materials such as aluminum, magnesium, silicon, carbon, and chromium through the advanced process. Kerui Refractory’s factory now has a large inventory of high-quality refractory bricks. We can deliver quickly when our partners need us.

According to the manufacturing process, they can be divided into sintered fire brick blocks, unsintering fire bricks, electric-melted bricks, and others. Different manufacturing processes have an impact on the properties and prices of fire brick material.

Key Features of Fire Bricks

- Save resources: Fire bricks have high refractoriness. Among them, the magnesia chrome brick can work at 1650 degrees Celsius. They can work for a long time in high-temperature environments. They have a long service life. It can help save brick wear and tear and maintenance costs.

- Extend equipment life: They have strong thermal shock resistance. And their wear resistance and flexural strength are high. This effectively resists wear and tear from high mechanical strength. This helps to extend the service life of high-temperature equipment in kilns.

- Strong operability: It can be cut to adjust the size according to customer needs.

- Customization: Kerui Refractory provides different solutions according to customer needs, including volume, thickness, color, composition, etc.

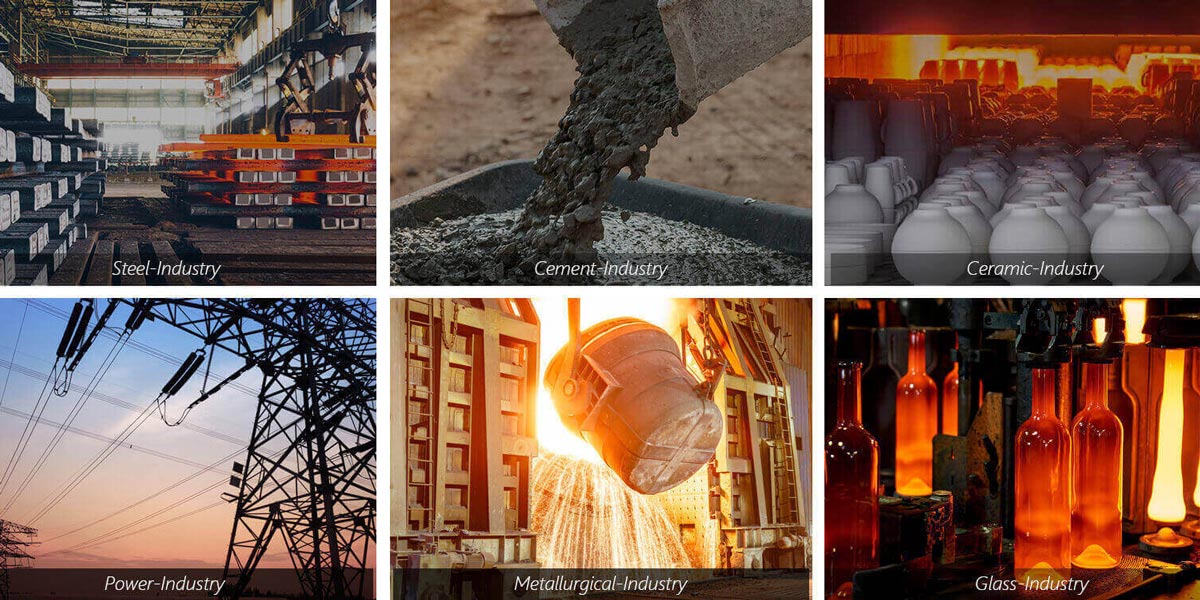

What is Fire Brick Used For?

This fire brick liner is mainly used in the steel industry, non-ferrous metal smelting industry, ceramics industry, glass industry, cement industry, etc. They are commonly used as high-temperature materials for linings, flues, pipes, etc.

- Steel industry: blast furnaces, electric arc furnaces, open hearth furnaces, converters, refining furnaces, etc.

- Non-ferrous metal smelting industry: blast furnaces for ironmaking, electric arc furnaces for steelmaking, aluminum electrolysis furnaces, refining furnaces, etc.

- Ceramics industry: tunnel kilns, shuttle kilns, roller kilns, lifting kilns, resistance furnaces, induction furnaces, etc.

- Glass industry: melting furnaces, forming furnaces, annealing furnaces, etc.

- Cement industry: dry process kilns, wet process kilns, etc.

- Chemical industry: reactors, heaters, distillation towers, etc.

- Environmental protection industry: incinerators, desulfurization furnaces, denitrification furnaces, etc.

Which Brick is Best for Fire?

Each brick has a different application environment, like AZS refractory brick, silica refractory brick. Therefore, Kerui Refractory needs to understand the partner’s industrial environment to recommend the appropriate brick. In the same application environment, there are bricks with high cost performance and high performance.

Many situations can cause wear and tear on fire bricks, such as temperature, corrosion, mechanical conditions, humidity, and work intensity. Therefore, partners can send us detailed information so that Kerui’s professional technicians can provide you with a suitable and cost-effective fire brick solution.

Where to Buy Fire Brick?

Kerui Refractory, as a refractory manufacturer, has a large amount of high-quality fire bricks for sale in stock. These fire bricks are of excellent quality and international dimensions. We can provide customers with relevant company certificates, product patent certificates and quality inspection reports. Choosing Zhengzhou Kerui Refractory Co., Ltd. is your worthwhile choice.

- Kerui uses advanced production processes to manufacture fire bricks. This ensures high quality and consistent performance.

- Complete certificates and patents: We have obtained various certificates and patents for Kerui fire bricks. This demonstrates our commitment to quality and innovation.

- Factory prices and volume discounts: We offer competitive factory prices for Kerui firebrick for sale. And we provide even more favorable discounts for large orders.

- Fast delivery of in-stock items: Kerui Refractory maintains a large inventory of fire bricks. This allows us to deliver your order quickly and efficiently.

- Customization of special-shaped fire bricks: We can customize special-shaped firebrick lining to meet your specific needs.

Kerui Refractory is a reliable and experienced refractory manufacturer with a proven track record of providing high-quality products and services. We offer a wide range of fire bricks to meet the diverse needs of various industries. Contact us today or follow Kerui on LinkedIn to learn more about Kerui fire bricks and how we can help you meet your specific needs.