Zirconium corundum refractory brick is expertly made to withstand the harshest conditions in the glass industry. Kerui Refractory offers customized solutions and comprehensive technical support for this product.

- ZrO2: 33.5-41%;

- SiO2: 12-15%;

- Bulk Density: 3.8-4.05g/cm³;

- Cold Crushing Strength≥70MPa;

- Apparent Porosity: 0.6-0.8%;

- Size: Customized sizes;

- Delivery: 15-30 working days;

Parameter of Zirconium Corundum Refractory Brick

Zirconium corundum refractory brick, also known as AZS brick, is a high-performance refractory material made from a combination of alumina (Al2O3), zirconia (ZrO2), and silica (SiO2). Choose the suitable types.

| Item | AZS41 | AZS36 | AZS33 |

|---|---|---|---|

| SiO2, % | 12 | 13 | 15 |

| Al2O3, % | The Remainder | The Remainder | The Remainder |

| ZrO2, % | 41 | 36.5 | 33.5 |

| Fe2O3+TiO2+CaO+MgO+Na2O+K2O, % | ≤2.0 | ≤2.0 | ≤2.0 |

| Bulk Density, g/cm3 | 4.05 | 3.9 | 3.8 |

| Apparent Porosity, % | 0.6 | 0.8 | 0.7 |

| Initial Precipitation Temperature of Vitreous Phase, ℃ | 1400 | 1400 | 1400 |

| Vitreous Phase Exudation, % (1500℃*4h) | 1.5 | 2.3 | 2.0 |

| Anti-molten Glass Erosion Speed Under Static Condition, mm/24h (1500℃*36h, ordinary soda lime glass) | 1.2 | 1.3 | 1.4 |

| Bubble Release Rate, % (1300℃*10h, ordinary soda lime glass) | 0.6 | 1.0 | 1.2 |

Key Advantages of Kerui Zirconium Corundum Fire Brick

- Exceptional Thermal Stability: Withstands temperatures up to 1800°C (3272°F), ensuring reliable performance in high-heat applications.

- Superior Corrosion Resistance: Resists chemical attacks from molten metals, glass, and slag, extending the lifespan of industrial furnaces.

- High Mechanical Strength: Maintains structural integrity under heavy loads and mechanical stress, reducing the risk of cracking or deformation.

- Excellent Thermal Shock Resistance: Performs consistently under rapid temperature changes, minimizing downtime and maintenance costs.

- Low Porosity: A dense structure prevents penetration of molten materials, enhancing durability and efficiency.

Applications of Zirconium Corundum Brick

Kerui zirconium corundum brick is widely used in the following industries:

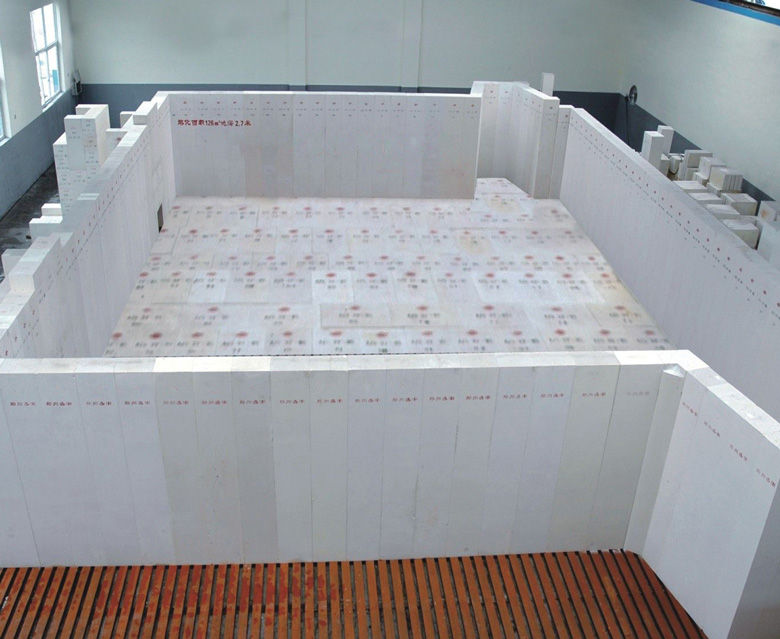

Glass Industry: Lining for glass melting furnaces, regenerators, and feeders.

Customer Feedback for Kerui Zirconium Corundum Refractory Blocks

Here’s what our customers have to say about Kerui zirconium corundum refractory brick:

“The AZS bricks from Kerui have significantly improved the efficiency of our glass melting furnace. Their durability and thermal stability are unmatched.” – Glass Manufacturer, Germany.

“We’ve been using Kerui’s refractory bricks for over five years, and they consistently deliver excellent performance. Highly recommended!” – Glass Plant, Egpyt.

Why Choose Kerui Refractory?

- Advanced Manufacturing Technology: We use advanced equipment and processes to ensure consistent quality and performance in factory.

- Custom Solutions: Our team can tailor the bricks to meet specific size, shape, and performance requirements.

- Rigorous Quality Control: Every batch undergoes strict testing for density, thermal shock resistance, and chemical stability.

- Global Reach: With a presence in over 50 countries, we deliver our products worldwide with reliable logistics.

- Exceptional Customer Support: From technical consultation to after-sales service, we provide end-to-end support to ensure customer satisfaction.

- 20+ Years of Experience: Kerui Refractory has been a trusted name in the refractory industry for over two decades.

- Comprehensive Product Range: We offer a wide variety of refractory products to meet diverse industrial needs.

- Competitive Pricing: Our efficient production process allows us to offer high-quality products at affordable prices.

- Sustainability Commitment: We prioritize eco-friendly manufacturing practices and energy-efficient solutions.

Conclusion

Kerui zirconium corundum refractory brick is the ultimate choice for industries seeking reliable, high-performance refractory solutions. With its exceptional thermal stability, corrosion resistance, and durability, it is a good product for customers worldwide. If you’re looking to enhance the efficiency and lifespan of your glass furnaces, contact Kerui Refractory today. View some videos about Kerui on YouTube.