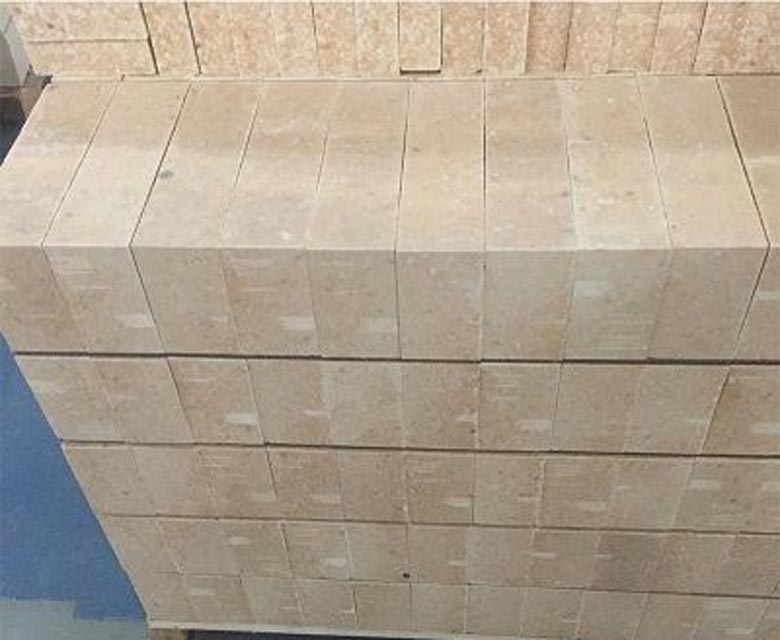

Zircon refractory brick uses zircon as a raw material. It is an acidic refractory brick that is usually used for glass kilns. The characteristics of Kerui zirconia brick are good mechanical shock resistance, stable chemical structure, and low thermal conductivity.

- ZrSiO4: ≥15-65%;

- Bulk Density: 2.7-3.7g/cm³;

- Refractoriness Under Load: 1550-1650ºC;

- Cold Crushing Strength: ≥100MPa;

- Size: 230*114*65mm (standard)/And other sizes;

- Delivery: 15-30 Working Days;

Technical Data of Zircon Refractory Brick

| Item | Dense zircon brick | Zircon brick | zirconium -corundum brick | Zirconium -mullite brick | Semi-zircon brick |

|---|---|---|---|---|---|

| ZrO2 % | ≥65 | ≥60 | ≥30 | ≥18 | ≥15-20 |

| Al2O3 % | - | - | ≥45 | ≥55 | ≥50-60 |

| SiO2 % | - | ≤38 | ≤25 | ≤25 | ≤20 |

| Fe2O3 % | ≤0.3 | ≤0.5 | ≤0.5 | 1.2 | 1.2 |

| Apparent porosity % | ≤18 | ≤22 | ≤20 | ≤17 | ≤20 |

| Bulk density g/cm3 | ≥3.7 | ≥3.5 | ≥3.2 | ≥2.7 | ≥2.7 |

| Cold compressive strength MPa | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 |

| Refractoriness under load°C | ≥1650 | ≥1620 | ≥1650 | ≥1650 | 1550 |

Characteristics of Zirconia Refractory Brick

- Excellent Thermal Shock Resistance: Kerui zirconia refractory can resist thermal shock. In glass kilns, hot air will shock the refractory linings. The refractory bricks may crack or damage. Zirconia refractory can avoid this situation because of the excellent thermal shock resistance. It can effectively extend the life cycle of high-temperature equipment.

- Good Mechanical Shock Resistance: Zircon refractory bricks can resist mechanical shock resistance because of the high density of the structure. In the production process, equipment will receive various mechanical shocks. They can used for the vulnerable parts of industrial furnaces to prolong the service time.

- Stable Chemical Structure: Zircon refractory is an acidic refractory brick that can be used for glass kilns. It can resist acidic chemical solutions and slags. In this situation, zircon brick will not affect the production. It is an ideal refractory brick for glass kilns.

- Low Thermal Conductivity: Zircon bricks have low thermal conductivity. It can sustain high temperatures in industrial equipment. The low thermal conductivity helps improve energy utilization. Moreover, it has good electric insulation that can use electronic materials.

Applications of Zirconia Bricks

Zirconia bricks are used for key parts of glass kilns, steel furnaces, picture tube furnaces, metallurgical furnaces, and other high-temperature industrial furnaces. It can be used for the top, bottom, and lining of furnaces. Our technicians have abundant experience in zirconia bricks. We have completed lots of cases about different industrial high-temperature equipment.

Global Cases of Zircon Refractory Bricks Around the World

More than 1000+ partners purchased products of Kerui Refractory. These partners got refractory kiln solutions and a series of products. Before shipment, Kerui Refractory will check products from quality to packaging. We will ensure that each refractory product is of high quality and arrives intact at the partners’ site.

Kerui Professional Technician Served for Partners

Kerui has a professional technician team that can give the most professional advice to customers. We offer customized service for customers.

- 20+ years of experience in technical guidance;

- Provide a combination solution of refractory products;

- Offer professional drawing design;

Kerui Certificates and Qualifications

Kerui Refractory, as the leading manufacturer of refractory products in China, has numerous international certifications, patent certificates, and corporate honors. We have earned the recognition of numerous customers for our technology, product quality, and corporate strength.

Comprehensive Service

Kerui can provide all aspects of service for customers, including the construction of zircon refractory brick. We can design optimal plans for customers according to different industrial equipment and situations. Customers can experience turnkey service in Kerui. If you are interested in our factory, you can watch our factory video on YouTube.