Z Block Insulation

Z block insulation provides superior thermal insulation for high-temperature industrial furnaces. Its ultra-dense ceramic matrix can withstand temperatures up to 1600°C. This solution provides 40% greater insulation effectiveness than standard insulation blocks and is 50% faster to install. One Cree customer reported a threefold increase in service life. Cree offers ISO-certified manufacturing and 24/7 global support. It’s built to handle your most demanding high-temperature applications.

- Free Sample:

- Available

- Document:

- MSDS supporting

- Performance Test:

- Support

- Shipment:

- 7-15 working days

Parameters of Kerui Z Block Insulation

KERUI Z-type insulation blocks utilize high-quality ceramic fiber, high-purity adhesives, and a reinforced anchoring system for quick installation and superior thermal performance. They are the most commonly used structure among ceramic fiber modules. View the specification.

| Item/Grade | STD MODULE | HP MODULE | HA MODULE | HZ MODULE | |

|---|---|---|---|---|---|

| Classification Temperature/℃ | 1260 | 1260 | 1350 | 1430 | |

| Chemical Composition | ω (Al2O3) ≥/% | 43 | 44 | 52 | 35 |

| ω (SiO2) ≥/% | 54 | 55 | 47 | 49 | |

| ω (ZrO2) ≥/% | / | / | / | 15 | |

| Color | White | White | White | White | |

| Bulk Density (kg/m³) | 160-220 | 160-220 | 160-220 | 160-220 | |

| Permanent Linear Change ≤/% | 1000℃*24h 2.5 | 1100℃*24h 2.5 | 1200℃*24h 3.0 | 1350℃*24h 3.0 |

|

| Thermal Conductivity Coefficient/[W/(m·K)] | 400℃ | 0.1 | 0.1 | 0.1 | 0.1 |

| 600℃ | 0.18 | 0.17 | 0.16 | 0.15 | |

| 800℃ | 0.2 | 0.2 | 0.2 | 0.19 | |

| 1000℃ | 0.27 | 0.26 | 0.26 | 0.26 | |

Note: Asbestos Free.

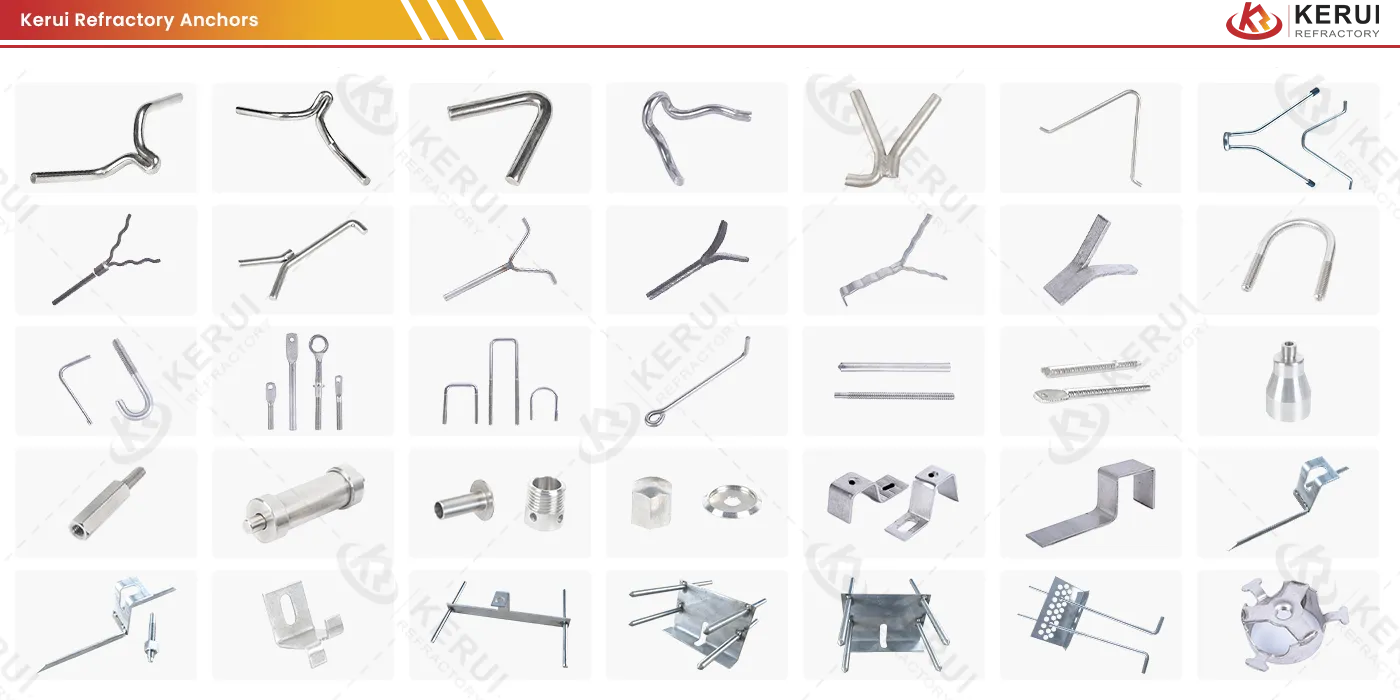

Composition of Z Module Insulation

The construction of Z block insulation involves a combination of materials and components that work together to deliver optimal performance:

- Made from premium Kerui ceramic blanket material;

- Accordion design ensures perfect furnace contour fitting;

- Stainless steel refractory anchors, beams and sliding channels;

- Enables quick 305x305mm module installation;

- Removable banding for tight, gap-free expansion;

- Fully isolates metal components from heat.

Features of Kerui Block Insulation

- Made from a laminate of high-purity ceramic fiber blankets;

- Welded to the steel shell with stainless steel bolts for enhanced mechanical strength.

- Self-expanding fibers create 100% gap-free lining;

- Maintains uniform temperature distribution;

- Withstands 1500°C thermal shocks;

- Resists mechanical vibration and impact;

- 40% lower heat storage than conventional linings;

- Reduces cycle times by up to 35%;

- Lightweight design (70% lighter than brick);

- Minimizes furnace structural stress;

- Ceramic fiber modular system installs 3X faster than traditional methods;

- Ready for immediate operation (no curing required).

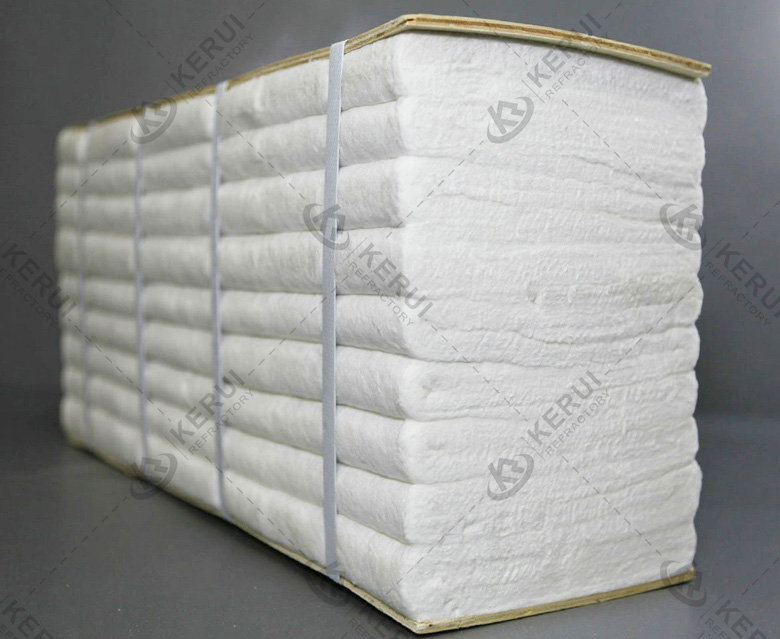

High-quality Production of Kerui Z Refractory Module Insulation for Sale

Applications of Insulation Block

Kerui’s block is utilized by a diverse range of industries worldwide, including:

- Iron & Steel Industry: Blast furnaces, ladle covers, annealing lines;

- Non-Ferrous Metals Production: Aluminum smelters, copper refining furnaces;

- Glass Manufacturing: Float glass lines, glass melting furnaces;

- Cement & Lime Processing: Rotary kilns, preheaters;

- Petroleum & Chemical Plants: Cracking furnaces, reformer units;

- Power Generation: Boiler insulation, SCR systems;

- Mining & Minerals: Calcination furnaces, roasting ovens.

Material Selection Guide for Z Insulation Block

Choosing the right type of blanket for block is crucial for optimal performance. Many factors must be considered.

Operating Temperature

- Match the ceramic fiber products grade to your maximum process temperature;

- Standard options: 1260°C / 1350°C / 1430°C rated materials;

Process Requirements

- Consider furnace atmosphere (oxidizing/reducing);

- Evaluate thermal cycling frequency;

- Account for mechanical stress factors;

Product Protection

- Select low-shot-content grades for clean environments;

- Choose chemical-resistant formulations when needed.

Good Reviews for Kerui Z Block Module Insulation

Contact Kerui Refractory for Certificated Products

Precisely engineered for optimal performance, Kerui Z Block Insulation integrates advanced thermal break technology with durable composite materials and sustainable insulation fillers. This innovative combination delivers good energy efficiency and unmatched structural reliability.