Insulation brick is a kind of refractory brick that has insulation ability. It can used in high-temperature industrial equipment to help keep the heat and reduce the heat transfer.

Five Hot Selling Insulation Bricks

High Alumina Insulation Brick

- Al2O3, %: ≥48;

- Thermal Conductivity Coefficient, W/(m.k): 0.2-0.55;

- Cold Crushing Strength, MPa: 1.0-4.5;

Fire Clay Insulation Brick

- Al2O3, %: 30-46;

- Thermal Conductivity Coefficient, W/(m.k): 0.23-0.65;

- Cold Crushing Strength, MPa: 0.8-6.0;

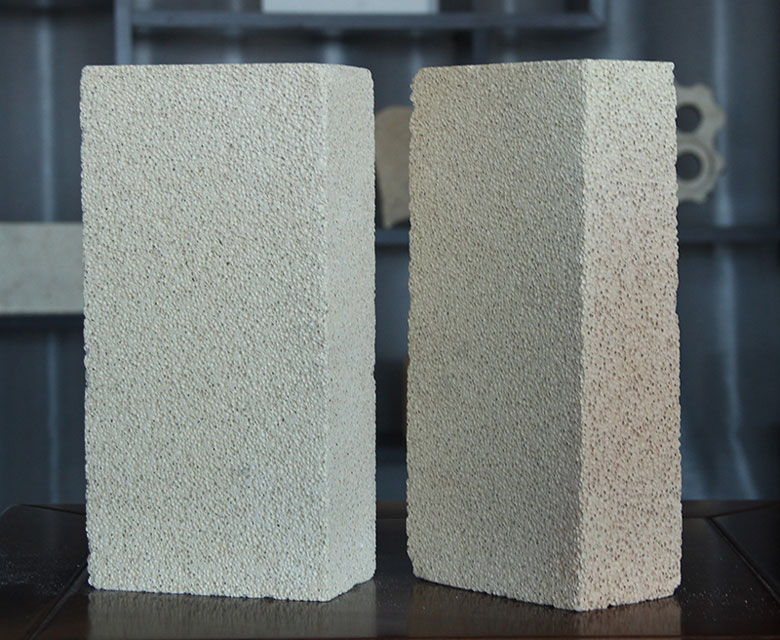

Mullite Insulation Brick

- Al2O3, %: 40-77;

- Thermal Conductivity Coefficient, W/(m.k): 0.18-0.56;

- Cold Crushing Strength, MPa: 0.9-3.5;

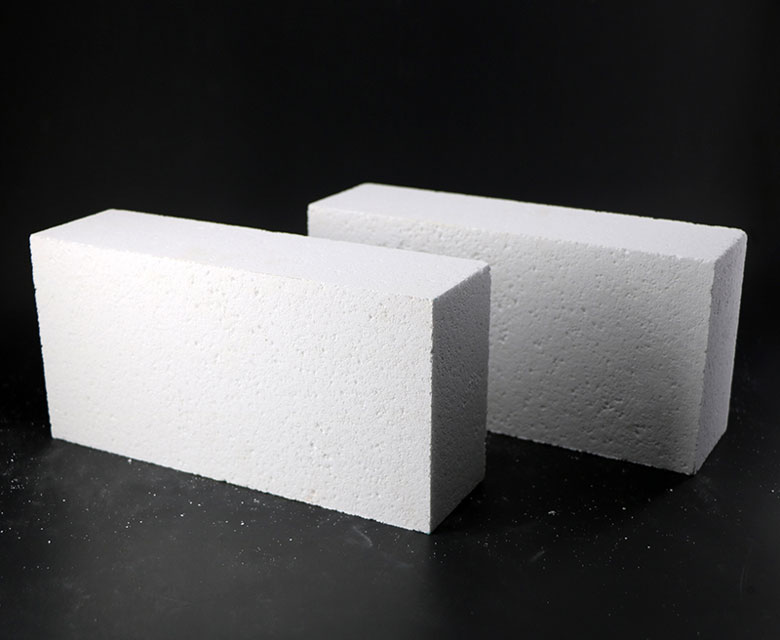

Silica Insulation Brick

- SiO2, %: ≥91;

- Thermal Conductivity Coefficient, W/(m.k): 0.55-0.7;

- Cold Crushing Strength, MPa: 2-5;

Alumina Bubble Brick

- Al2O3, %: 90-99;

- Thermal Conductivity Coefficient, W/(m.k): 0.9-1.2;

- Cold Crushing Strength, MPa: 6-18;

Size of the Insulation Bricks

Standard size:230*114*65mm

There are many different shapes of insulation bricks, including knife bricks, axe bricks, universal ladle bricks, and so on. If you need customized special shape bricks, please provide the specifications of the bricks.

How to Choose the Best Suitable Insulation Bricks?

Insulation bricks have an excellent thermal insulation effect that can keep the heat to improve energy utilization. They all have low thermal conductivity that can reduce the heat transfer to enhance heat utilization. They also have good thermal shock resistance that can resist the high-temperature and high-pressure situations. This feature is conducive to keeping the volume of the high-temperature equipment. However, different insulation bricks are suitable for different industrial equipment.

High Alumina Insulation Brick

High alumina insulation bricks can not used for industrial equipment that needs direct contact with flame or to resist chemical erosion. High alumina insulation bricks are used for the linings of high-temperature equipment, including ceramic tunnel kilns, hot-air stoves, coke kilns, and so on.

Fire Clay Insulation Brick

Fire clay insulation brick can resist the acid solution erosion. It also cannot directly contact flame. Fire clay insulation bricks can be widely used in many industrial high-temperature equipment, including blast furnaces, hot blast stoves, cement kilns, glass kilns, and so on.

Mullite Insulation Brick

Mullite insulation brick has lots of pores on the surface. So it has great insulation ability. Besides, mullite insulation brick can resist the acid and alkaline erode situation. So it can used for glass furnace regenerator chambers, ceramic sintering kilns, and other high-temperature kiln linings. It is also used for the top of hot blast kilns, and so on.

Silica Insulation Brick

Silica insulation brick is an acid insulation brick. It can resist acid chemical gas erosion. The surface of silica bricks has a lot of pores. These pores decrease the weight of the bricks. So silica insulation bricks are lighter than other insulation bricks. Silica insulation brick is mainly used in the insulation layer of blast parts of hot blast stoves, rolling furnace tops, natural gas pipelines, and so on.

Alumina Bubble Brick

Alumina bubble bricks have excellent insulation ability. The bulk density and the thermal conductivity are low. These features make the alumina bubble bricks sustain the temperature of industrial equipment. Alumina insulation brick is usually used for the linings of ceramic kilns, cracking furnaces, glass kilns, refuse incinerators, and other high-temperature industrial equipment.

Prices of Insulation Bricks

The prices of these insulation bricks are listed from lowest to highest: fire clay insulation bricks, silica insulation brick, high alumina insulation brick, mullite insulation brick, and alumina bubble brick. Kerui will give a low price of insulation brick because we have our own factory.

High-quality Insulation Bricks

Choosing a high-quality insulation brick is very important. The high-quality insulation bricks help to sustain the stability of the industrial equipment. When using the inferior insulation brick in high-temperature equipment, it may decrease the energy utilized even have an accident.

Kerui will provide high-quality insulation bricks to every customer. Our refractory materials all passed the certification of international institutions, including ISO, SGS, and so on.

Supplier of Insulation Bricks

Choosing a good supplier also helps to find the best insulation bricks. Kerui sells five common insulation bricks on our website. You can directly contact us on our website. There are no businessmen between Kerui and customers. Besides, If you need any suggestions, Kerui has a professional technology team to offer all the details about insulation bricks. Many customers found the most suitable refractory materials by our guidance. As a professional supplier, we have abundant export experience, and our refractory products have been exported to more than 50 countries.

Conclusion

Although the fire clay insulation brick is the cheapest, it does not mean that it is not the best insulation brick for you. You should choose a suitable brick for your high-temperature equipment. The most suitable brick is the best.