SK34 firebrick is an important type of refractory material. It is primarily used in high-temperature environments, such as kilns and furnaces in industrial equipment. Kerui offers a wide range of options for customers, like size. 100+ customers purchase SK34 refractory bricks from KERUI for use in kilns and boilers.

- Al2O3: ≥38-42%;

- Bulk Density: 2.1-2.2g/cm³;

- Refractoriness Under Load: 1250-1360ºC;

- Cold Crushing Strength: ≥30MPa;

- Size: 230*114*65mm (standard)/And other sizes;

- Customization: Customized Size Available;

- Free Sample: Available;

- Delivery: 15-30 Working Days;

Parameters of SK34 Firebricks

SK34 bricks are a Grade 3 high alumina refractory. They contain 38-42% alumina (Al₂O₃).

| Item/Grade | SK-34 | |

|---|---|---|

| Al2O3, % | 38-42% | |

| Fe2O3, % | 3.1 | |

| Apparent Porosity, % | 23 | |

| Bulk Density, g/cm³ | 2.15 | |

| Cold Crushing Strength, MPa | ≥ | 35 |

| Refractoriness underload, 0.2MPa, °C | ≥ | 1350 |

| Refractoriness | ≥ | 1760 |

| Thermal Expansion at 1000℃(%) | ≤ | 0.55 |

Standard and Custom Shapes of Kerui Fire Bricks SK34

Select appropriate specifications and dimensions based on actual needs to ensure the fire bricks fit tightly within the equipment.

- Kerui offers a variety of standard shapes and sizes for high-alumina bricks, including straight bricks, arch bricks, wedge bricks, anchor bricks, burner bricks, and so on. For standard shapes, Kerui usually maintains stock.

- In addition, Kerui can provide custom bricks according to customers’ drawings.

Features of Kerui SK34 Firebrick

- High refractoriness;

- Good thermal stability;

- Chemical stability;

- Slag resistance;

- Reduces energy consumption and improves equipment thermal efficiency;

- Extends equipment service life and lowers operating costs.

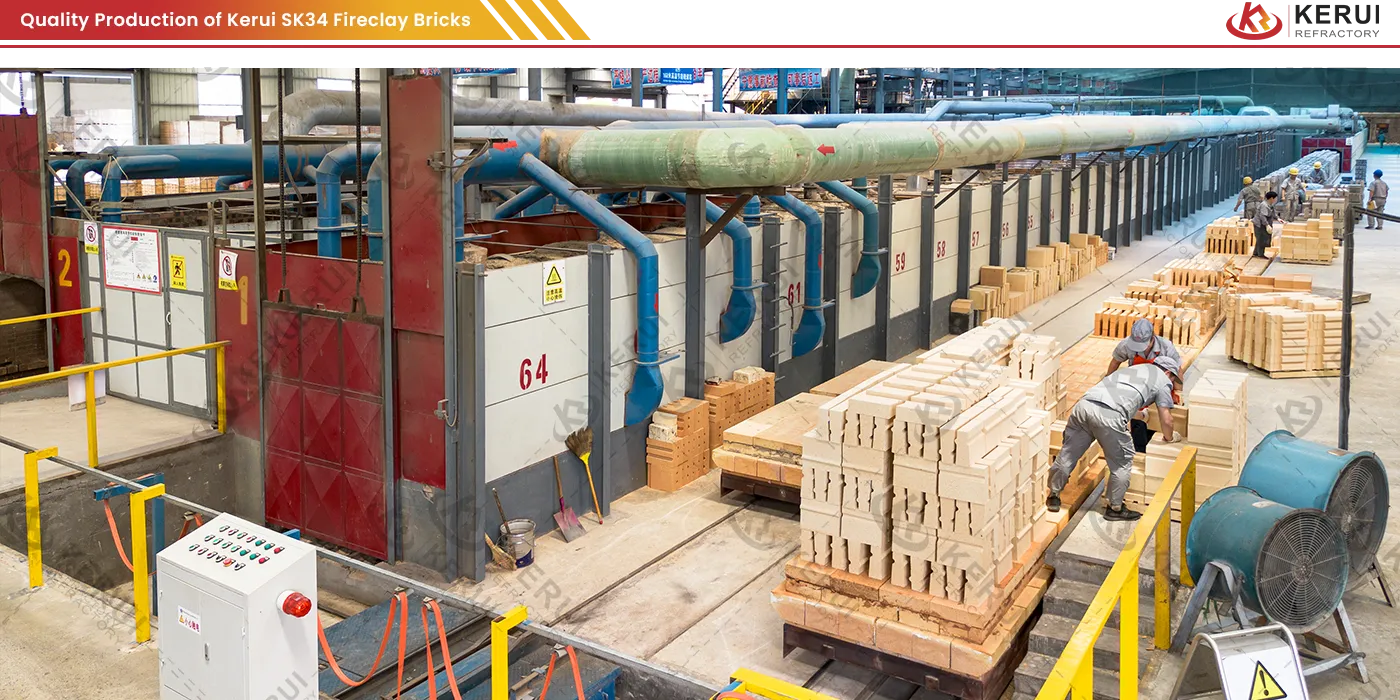

The Production of Kerui SK34 Fire Bricks

The production process of Kerui SK34 refractory bricks typically includes steps such as raw material preparation, molding, drying, and sintering.

- High-quality raw materials: Kerui selects premium raw materials to enhance the performance of refractory bricks.

- Precise proportioning: Accurate batching and mixing ensure the bricks achieve the desired chemical composition and physical properties.

- Molding: Over 40 pressure molding machines guarantee uniform brick density.

- Sintering: Two 168-meter-long tunnel kilns ensure thorough and uniform firing, resulting in excellent performance.

- Inspection and packaging: After production, the Kerui shipping team conducts sampling inspections of the bricks, followed by secure packaging for delivery.

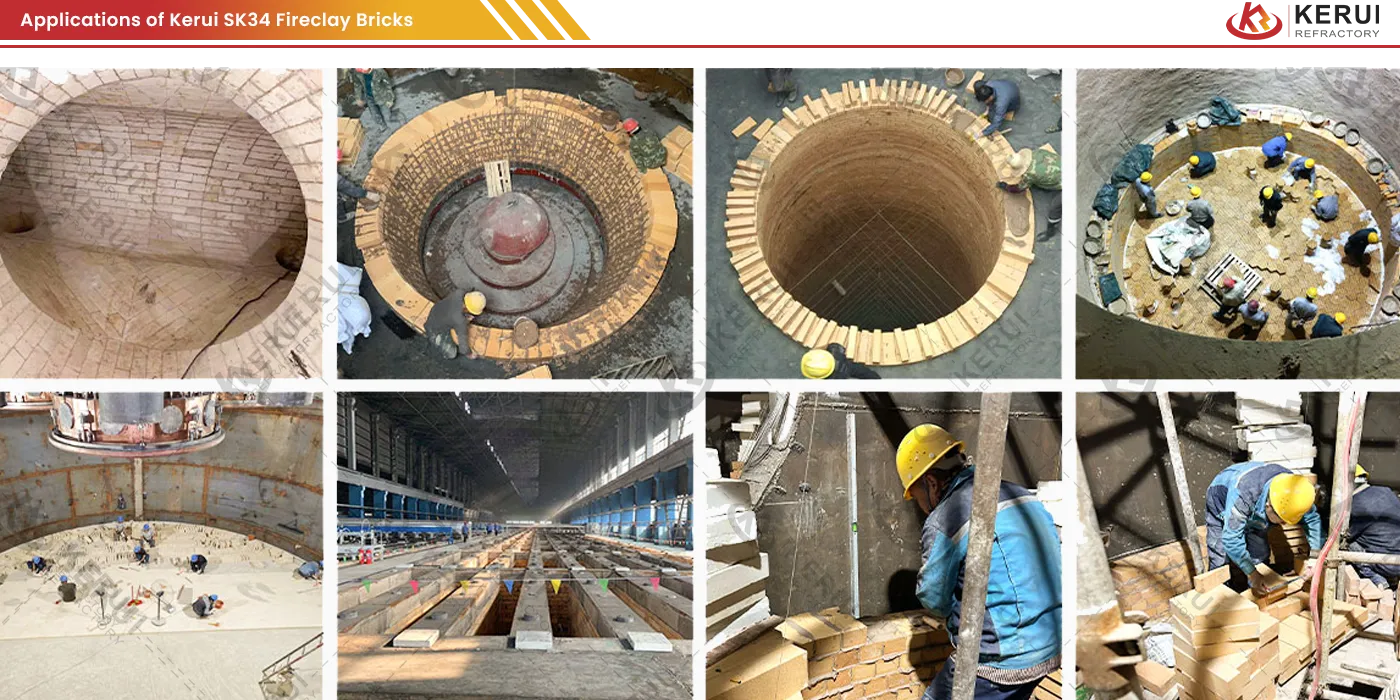

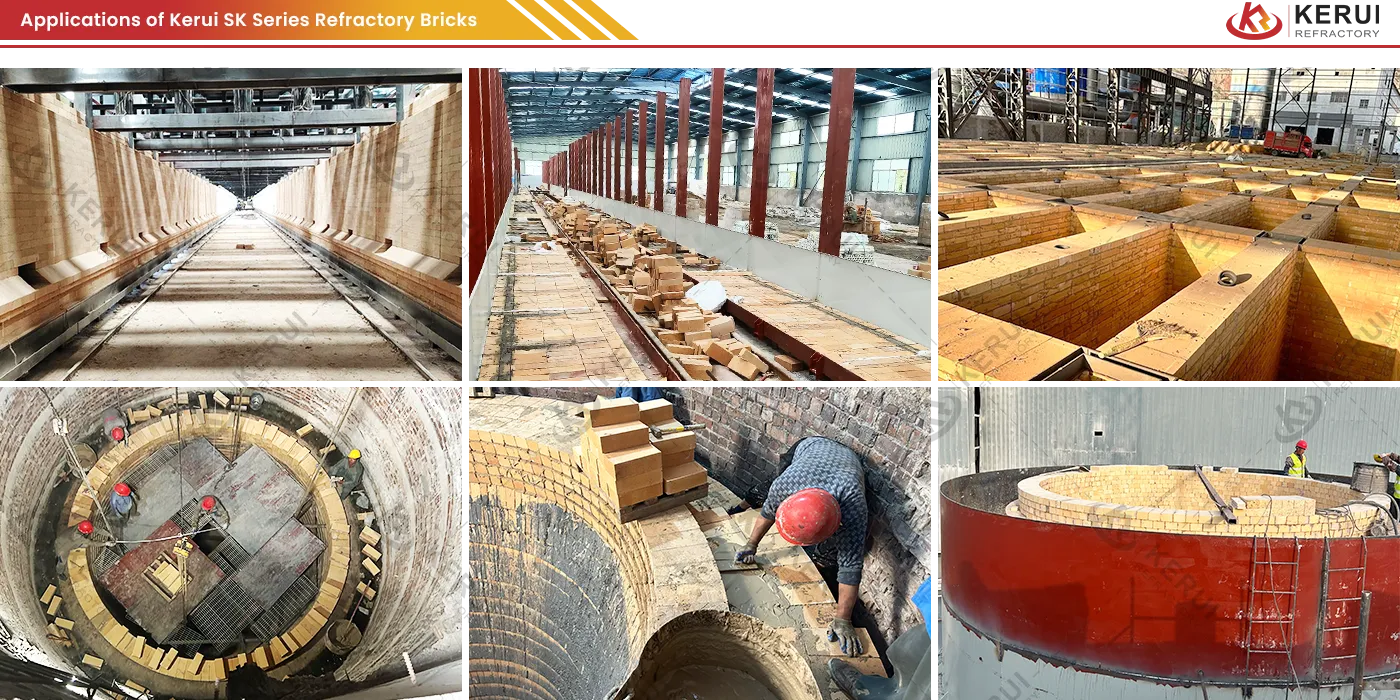

Kerui SK34 Firebrick Used in High-temperature Industry

Due to the excellent performance of SK34 refractory firebricks, they are widely used in various high-temperature industrial kilns.

- Steel and iron smelting industry: Used as parts of linings of blast furnaces, converters, hot blast stoves, electric furnaces, cupolas, soaking pits, heating furnaces, etc.

- Non-ferrous metal smelting: Used in melting furnaces for non-ferrous metals such as copper and aluminum.

- Glass manufacturing: Utilized in glass melting furnaces and related equipment.

- Cement industry: Applied in cement kilns and similar setups.

- Chemical industry: coking ovens, chemical industry kilns, etc.

- Petrochemical industry: Used in cracking furnaces, reactors, and so on.

- Ceramics industry: Applied to the inner walls and insulation layers of kilns to improve kiln efficiency and product quality.

Masonry Sites of Kerui SK34 Fire Bricks

Kerui SK34 clay bricks are widely used in numerous projects worldwide, including blast furnace, hot blast stove, rotary kiln, roasting furnace, furnace door lining brick, etc. These projects are running well, and our customers are very satisfied with the quality of our refractory bricks.

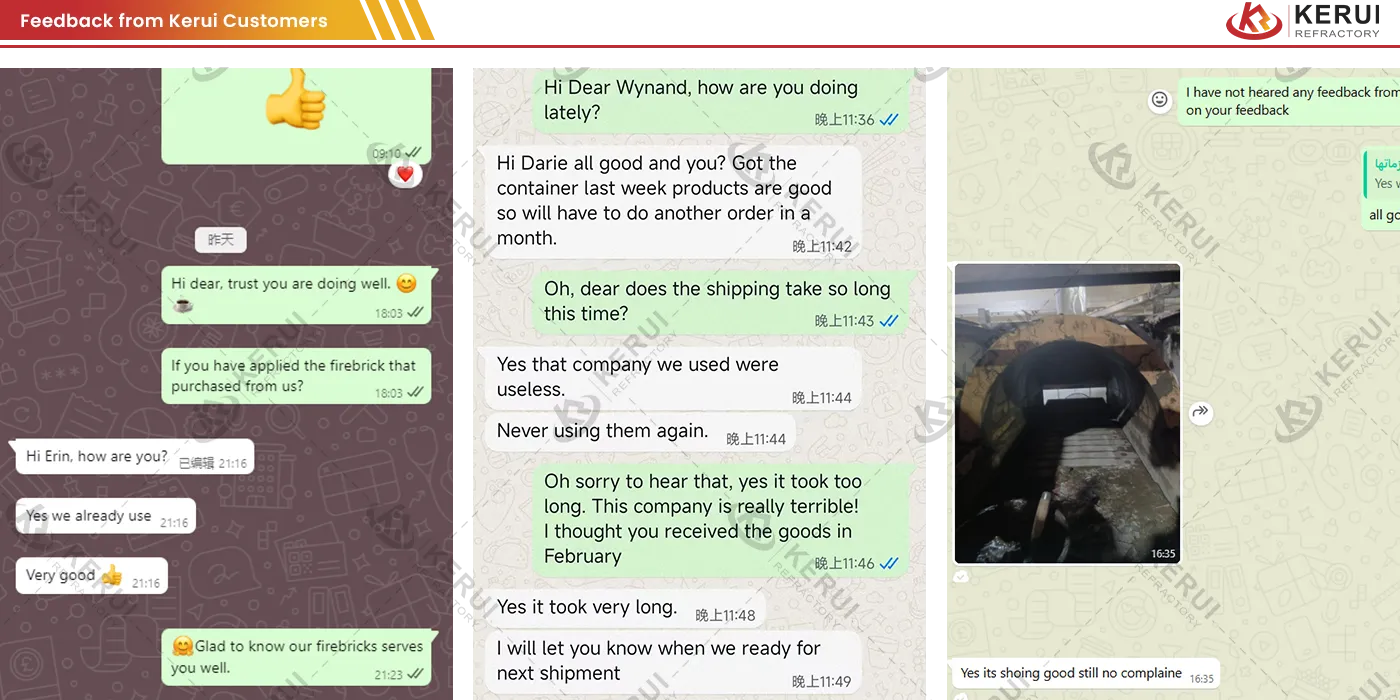

Kerui is Your Reliable Manufacturer of SK34 Fire Bricks

- Quality Control: Kerui’s factory implements a comprehensive production quality control system to ensure the final products meet standards.

- High Repurchase Rate: As a top manufacturer in China, Kerui enjoys high customer satisfaction, with 70% of clients choosing to repurchase our products.

- Technical Support: Our team of professional technicians provides product advice, solutions, and construction guidance.

- After-Sales Service: Kerui’s after-sales team offers on-site construction guidance. If necessary, the Kerui team can provide in-person support at the project site.

- Certificate: Kerui has a series of certificates and document for customer support, like ISO14001, ISO9001, CE, etc.

Choose Kerui to Cooperate With

Thanks to its excellent performance, SK34 firebricks are widely used in high-temperature industries. They not only provide solid support for industrial production but also extend the service life of kilns. Whether you need products or solutions, Kerui is your best choice. See more pictures of products on Pinterest.