Kerui Refractory offers a variety of SK fireclay bricks. We provide bricks with alumina content ranging from 30% to 70%. Our factory is equipped with advanced production facilities, strong production capacity, and customization capabilities. We are the first choice for various high-temperature industries. More than 100+ customers has cooperated with Kerui Refractory.

- Al2O3: ≥30-70%;

- Bulk Density: 1.9-2.35g/cm³;

- Refractoriness Under Load: 1250-1480ºC;

- Cold Crushing Strength: 30-50MPa;

- Size: 230*114*65mm (standard)/And other sizes;

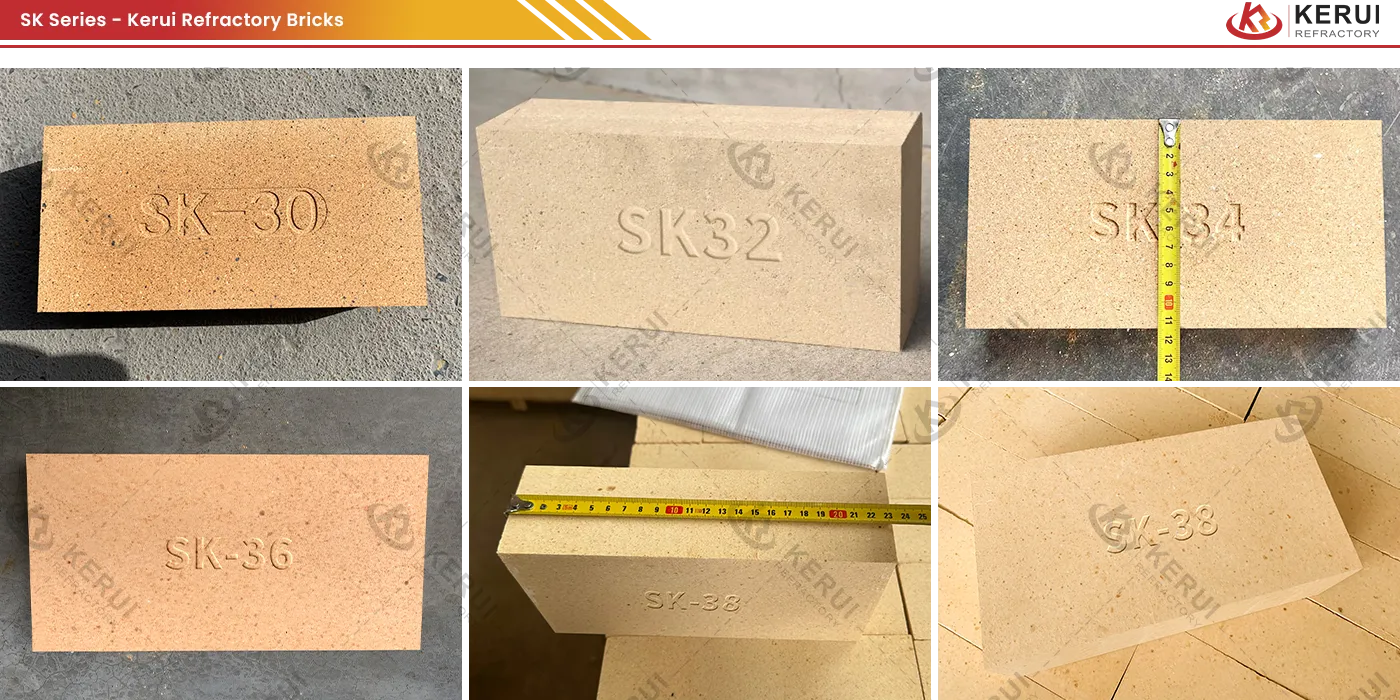

Basic Parameters of SK Fireclay Bricks

| Item/Grade | SK-30 | SK-32 | SK-34 | SK-36 | SK-38 | |

|---|---|---|---|---|---|---|

| Al2O3, % | 30-34% | 34-38% | 38-42% | 48-55% | 65-70% | |

| Fe2O3, % | 3.5 | 3.2 | 3.1 | 2.5 | 2.3 | |

| Apparent Porosity, % | 24 | 24 | 23 | 22 | 20 | |

| Bulk Density, g/cm³ | 2.05 | 2.1 | 2.15 | 2.2-2.25 | 2.25-2.35 | |

| Cold Crushing Strength, MPa | ≥ | 30 | 35 | 35 | 45 | 50 |

| Refractoriness underload, 0.2MPa, °C | ≥ | 1300 | 1330 | 1350 | 1380 | 1400 |

| Refractoriness | ≥ | 1650 | 1700 | 1760 | 1780 | 1810 |

| Thermal Expansion at 1000℃(%) | ≤ | 0.6 | 0.55 | 0.55 | 0.4 | 0.4 |

Note: We can also provide unconventional SK40.

Strict Production Process of SK Fireclay Bricks

- Production bases: Kerui’s factory is located in one of the largest production bases: Xinyi, Zhengzhou, Henan, China. We strictly control production quality to provide customers with higher quality and more stable performance refractory bricks.

- High-quality raw materials: High-grade bauxite and appropriate additives.

- Various production processes: Pressing, firing, and so on.

- Multiple advanced production equipment: Automatic precise batching equipment, 20 sets of 360-ton hydraulic presses, 2 high-temperature tunnel kilns of 168 meters, and so on.

Various Sizes Of SK Series Clay Refractory Bricks

The standard brick type provided by Kerui is straight, with dimensions of 230*110*25mm. Additionally, to meet the needs of various industries, we also offer a range of brick types, including various nozzle bricks, arch bricks, and so on.

Features Of SK Series Clay Refractory Bricks

- Excellent corrosion resistance and wear resistance;

- Good dimensional stability at high temperatures;

- Excellent thermal performance and acid resistance;

- High mechanical strength;

- Good thermal shock resistance;

- Good spalling resistance and chemical corrosion resistance;

- Relatively lower price compared to high-alumina bricks.

Applications of SK Fireclay Bricks

SK clay refractory bricks are suitable for various high-temperature industrial applications.

Note: Contact us to get the uses detials of fire clay bricks.

| Series | Key Characteristics | Typical Applications |

|---|---|---|

| SK30 | Relatively lower refractoriness. | Industrial furnaces with lower operating temperatures, such as general heating furnaces, rotary kilns, boilers, and common kilns. |

| SK32 | Slightly higher refractoriness than SK30; suitable for medium temperatures. | Furnace linings requiring moderately higher temperatures, such as glass kilns, ceramic kilns, and lime kilns. |

| SK34 | Suitable for higher temperatures; good chemical corrosion resistance. | High-temperature kilns, such as steelmaking furnaces, aluminum alloy furnaces, and heat treatment furnaces in the petrochemical industry. |

| SK36 | Higher thermal shock resistance and refractoriness; suitable for complex chemical environments. | High-temperature equipment in steel (blast furnaces, electric furnaces, ladles), petrochemical, glass, and cement industries. |

| SK38 | Highest refractoriness and chemical corrosion resistance; for extreme conditions. | Furnace linings in extremely high-temperature and harsh environments, such as electric arc furnaces and high-temperature calcination kilns. |

Fast Shipment of SK Fireclay Bricks

For packaging, Kerui factory uses international standards for product packaging and ships according to the date agreed upon with the customer.

- Packaging: Fumigated wooden pallets.

- Standard Quantity: One pallet can hold 500-600 standard bricks.

- Delivery Time: 15-35 days (for stock availability).

- Shipping: Kerui can assist you in planning the most cost-effective and fastest shipping route.

50+ Customers Chose Kerui

Kerui is Your Trusted Supplier

- OEM: Kerui is a company that integrates manufacturing and supply. We offer customers favorable factory prices.

- Solutions: We not only provide high-quality products but also offer suitable refractory solutions for our clients.

- Customized Products: We can customize molds to produce special-shaped bricks according to customer drawings.

- After-Sales Service: Based on customer needs, our technical experts can visit the site for technical guidance and installation support.Please see some news on Linkedin.