Silicon carbide refractory brick is made primarily from high-purity silicon carbide. This brick has good properties. They are widely used in industrial applications. Kerui Refractory can provide you with kiln design solutions and specific demand calculations. Please send us your detailed requirements.

- SIC: ≥20-90%;

- Fe2O3: ≤0.6-1.5%;

- Bulk Density: 2.3-2.7g/cm;

- Cold Crusing Strength: 80-100MPa;

- Refractoriness Under Load: 1600-1700ºC.

- Size: 230*114*65mm (standard)/And other sizes.

Specifications of Kerui Silicon Carbide Refractory Bricks

Choose the right components and technical parameters based on the different chemical compositions to start your high-temperature project!

| Item | Index | |

|---|---|---|

| SiC, % | ≥ | 85 |

| Fe2O3, % | ≤ | 0.5 |

| Apparent Porosity, % | ≤ | 16 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1750 |

| Bulk Density, g/cm³ | ≥ | 2.6 |

| Cold Crushing Strength, MPa | ≥ | 80 |

| Modulus of Rupture, MPa | ≥ | 40 |

![]()

Types of Kerui SIC Bricks

Kerui silicon carbide (SiC) bricks are primarily categorized into the following types, each designed to meet specific application needs. Please review the characteristics of each type below to better understand their distinctions and select the most appropriate option for your project requirements.

| Types | Features |

| Oxide Bond SiC Brick | High refractoriness: 1750ºC; High-temperature strength; Good wear resistance; Good thermal shock resistance; Good corrosion resistance. |

| Corundum Silicon Carbide Brick | High refractoriness: 1900ºC; High-temperature strength; Good wear resistance; Good corrosion resistance. |

| Mullite Silicon Carbide Brick | High refractoriness: 1750ºC; High-temperature strength; Good wear resistance; Good thermal shock resistance; Good acid resistance. |

| High Alumina SiC Brick | High refractoriness: 1750ºC; High-temperature strength; Good wear resistance; Good thermal shock resistance; Good alkali resistance. |

Besides, this kind of brick can also be divided by the difference in the bonding method:

- Oxide-bonded (clay-bonded, mullite-bonded, corundum-bonded);

- Nitride-bonded (Si3N4-bonded silicon carbide bricks, sialon-bonded silicon carbide bricks);

- Self-bonded (β-SiC-bonded and recrystallized);

- Silicon-infiltrated reaction-bonded silicon carbide bricks.

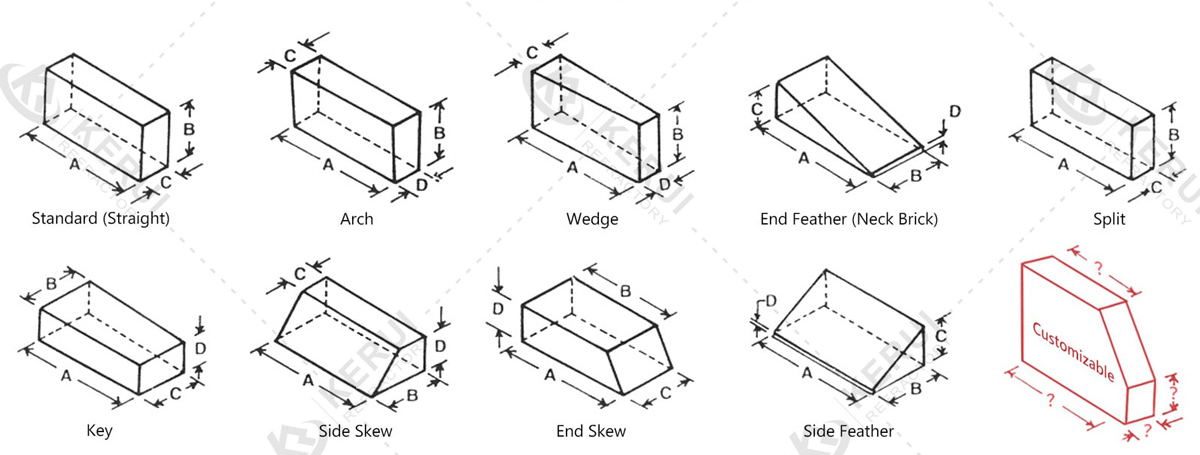

Different Sizes of Silicon Carbide Blocks

Advantages of Silicon Carbide Refractory Blocks

- High-temperature Resistance: The melting point of silicon oxide can reach 2730 °C. The refractoriness of silicon carbide bricks is as high as 1900 °C.

- High Mechanical Strength: The Mohs hardness of Kerui silicon carbide bricks is 9. It is very hard. In addition, its flexural strength and compressive strength are 1.5-3 times that of ordinary refractory bricks.

- High Thermal Conductivity: The thermal conductivity of silicon carbide can be more than 10 times that of ordinary refractory bricks. It has good thermal conductivity. Silicon carbide has a high thermal emissivity.

- Low Thermal Expansion: The dimension of silicon carbide brick changes very little when the temperature rises.

- Good Wear Resistance: Silicon carbide brick has extremely high hardness, second only to diamond.

- Corrosion Resistance: The composition of silicon carbide bricks has a good anti-corrosion effect on chemicals such as acids, alkalis and salts.

Silicon Carbide Refractory Blocks Applied in Different Industries

- Steel and Non-ferrous Metal Smelting: The silicon carbide refractory brick is used in non-ferrous metallurgical retorts (copper, aluminum, magnesium, lead, zinc, etc.), aluminum casting molds, electric furnace linings, aluminum electrolytic cell linings, blast furnaces, converters, open hearth furnaces, sintering furnaces, annealing furnaces, heating furnaces, ladles, tundishes, slag pots, etc.

- Industrial Applications: They are used in ceramic kiln furniture and heat exchangers, glass kilns, cement kilns, lime kilns, etc.

- Petrochemical Industry: They are commonly used in petroleum refining furnaces, reactors, pipelines, pumps, valves, etc.

- Power Industry: They are used in boilers, combustion chambers, desulfurization towers, dust collectors, chimneys, etc.

Silicon Carbide Bricks VS. Anti-Corrosion Carbon Bricks

| Attribute | Silicon Carbide Refractory Bricks (SiC) | Anti‑Corrosion Carbon Bricks |

|---|---|---|

| Main Composition | Silicon carbide (SiC) with various bonding agents (e.g. oxides, nitrides, self-bonded) | Carbon-based materials (coke, anthracite, graphite) bound with tar or resin |

| High‑Temperature Performance | Excellent; withstands extreme temperatures (~1600 °C+) with great thermal shock resistance | High refractoriness and thermal stability; low thermal expansion |

| Thermal Conductivity & Expansion | High thermal conductivity and low coefficient of thermal expansion | High thermal conductivity with minimal linear change; excellent thermal shock resistance |

| Wear & Abrasion Resistance | Outstanding wear resistance and mechanical strength | Strong abrasion resistance and load-bearing capacity |

| Chemical Corrosion Resistance | Good resistance to acids, alkalis, slags, and molten metals | Exceptional resistance to acids, alkalis, salts, solvents, molten metals and slags; but sensitive to oxidation |

| Typical Uses | Linings in high-wear, high-temperature industrial sectors (steel, nonferrous metallurgy, kilns, heat exchangers) | Used in corrosive high-temperature environments (blast furnaces, electrolytic cells, pickling baths, chemical reactors) |

Description of Kerui Silicon Carbide Bricks

Silicon carbide bricks are refractory bricks made by sintering silicon carbide and other fine powders at high temperatures.

- The addition of carbon monoxide can help improve the strength and wear resistance of the refractory bricks, while also helping to reduce costs.

- The addition of silicon dioxide can help improve the chemical corrosion resistance and thermal conductivity of the refractory bricks.

The combination of these two components gives the large refractory bricks excellent overall performance.

Kerui Refractory is Your Top Silicon Carbide Bricks Manufacturer

Kerui silicon carbide fire bricks have found their way into markets worldwide, serving industry giants like RUSAL, CHALCO, ALBA, POSCO, PSM, etc. Our collaborative approach, marked by technical exchanges and shared experiences, has led to continuous improvements in product quality and service.

We deliver customized refractory solutions that address our customers’ unique challenges. By optimizing production processes and reducing energy consumption, we empower our customers in the high-temperature industry to achieve greater efficiency.

Select Kerui Refractory as Your Silicon Carbide Bricks Manufacturer

Comprehensive Understanding of Needs

When we receive your requirements, Kerui Refractory will evaluate your planning and application of refractory products from multiple aspects, including performance, quantity, application locations, and so on. This can help you reduce the cost of time.

Customized Solutions

Kerui Refractory will provide customized silicon carbide refractory bricks based on customer requirements, including composition, size, shape, color, and so on. At the same time, Kerui Refractory will provide corresponding application design plans based on the customer’s application scenarios.

Quality Production

Kerui Refractory equips its factory with high-yield, high-quality production equipment. We ensure the timely and high-quality delivery of silicon carbide bricks and other refractory products to our customers. Our team tests both raw materials and final products and provides qualified test reports.

Customer-Centric Service

In order to save customers time and planning costs, Kerui Refractory provides customers with comprehensive one-stop services. We offer refractory silicon carbide refractory brick selection to construction guidance. We comprehensively assist customers in completing high-temperature industry projects. See some news on Kerui Linkedin.