Kerui Refractory has completed a large order of ceramic fiber products for a valued customer in Syria. This order shows Kerui’s commitment to providing high-quality thermal insulation solutions tailored to meet the specific needs of customers worldwide.

Ceramic Fiber Products for Syrian Customer in 2025

The order includes a variety of ceramic fiber products designed for excellent thermal insulation and durability. These products are ideal for high-temperature industrial applications, such as furnace linings, heat shields, and expansion joint fillers.

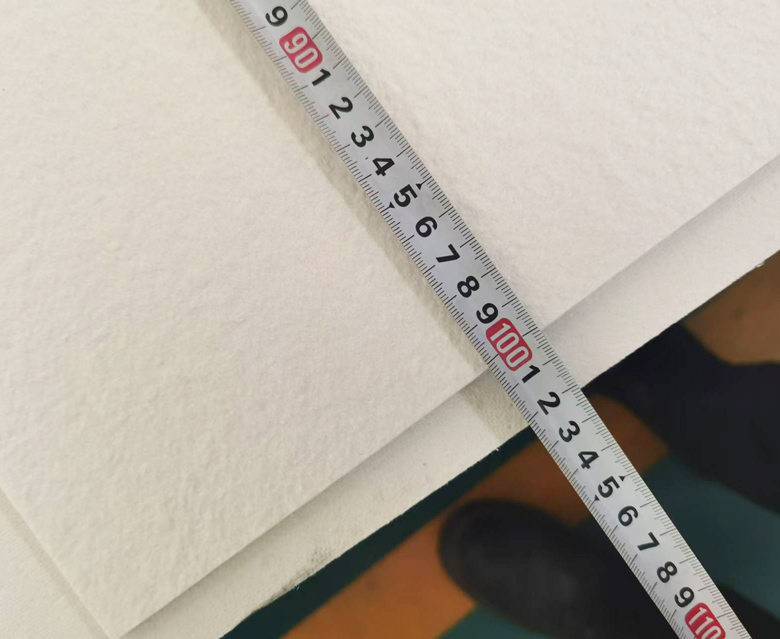

- Ceramic Fiber Boards

Thickness: 6mm, 8mm, and 10mm. - Ceramic Fiber Paper

Thickness: 3mm and 6mm. - Ceramic Fiber Blankets

Thickness: 25mm.

Production Process of Ceramic Fiber Products

Kerui’s advanced production facility ensured efficient and precise manufacturing. The process included the following steps:

- 1. Raw Material Selection

High-purity raw materials, like alumina and silica, were carefully chosen for optimal performance. - 2. Fiber Formation

The raw materials were melted and spun into fine ceramic fibers using advanced “blown” and “spun” processes. - 3. Product Shaping

The fibers were compressed and shaped into boards, paper, and 1260 ceramic fiber blanket, with precise thicknesses to meet the customer’s needs. - 4. Heat Treatment

The products underwent heat treatment to improve thermal stability and mechanical strength.

Quality Inspection and Packaging of Ceramic Fiber Products

Quality is a top priority at Kerui. After production, each product was rigorously inspected to ensure it met the highest standards.

- Quality Control Checks

Dimensions, density, and thermal conductivity were tested to confirm compliance with specifications.

Samples were tested under high temperatures to verify performance in extreme conditions. - Packaging

Ceramic fiber boards and blankets were wrapped in protective plastic and packed in sturdy cartons.

Ceramic fiber paper was rolled and packed in moisture-resistant packaging.

Preparing for Shipment of Ceramic Fiber Products to Syrian

With production and quality checks completed, Kerui is now preparing for shipment.

- Logistics Planning

The logistics team is working with shipping partners to ensure timely and secure delivery.

Export documentation, including certificates of origin and quality reports, is being prepared. - Customer Communication

The customer has been updated on the shipment schedule and will receive tracking information once the goods are dispatched. - Delivery Expectations

The products are expected to arrive within the agreed timeframe, ensuring minimal disruption to the customer’s operations.

Why Choose Kerui?

This successful order demonstrates Kerui’s strengths as a trusted partner for high-temperature insulation solutions:

- Advanced Technology

Kerui uses cutting-edge technology to ensure consistent quality and performance. - Customization Capabilities

We provide tailored solutions to meet the unique needs of each customer. - Global Expertise

With over 23 years of export experience, Kerui has served customers in more than 80 countries. - Commitment to Quality

Our products are certified to international standards, including ISO, SGS, and CE.

Conclusion

The completion of this order for our Syrian customer reflects Kerui’s dedication to quality, efficiency, and customer satisfaction. We are confident that these ceramic fiber products will deliver exceptional performance in their intended applications. Contact Kerui Refractory today. Let us help you achieve optimal thermal insulation solutions!