Mullite Insulation Brick

Mullite insulation brick has good thermal insulation effects. Kerui Refractory is an ISO certified manufacturer. With customized thermal design and 1600°C service capabilities, we have won the trust of more than 1,000 industrial partners in more than 50 countries around the world. Our product quality has also passed strict third-party certification.

- Free Sample:

- Available

- Document:

- Certificates Supporting

- Performance Test:

- Support

- Shipment:

- 7-35 working days

Common Grades of Mullite Insulation Bricks

In addition to the regular JM series, Keru also provides B grades, C grades and other grades of insulation bricks.

- JM series: JM23, JM26, JM28, JM30;

- B series: B4, B5, B7;

- C series: C1, C2;

Quality Production of Kerui Mullite Insulation Bricks

Video of Kerui Mullite Insulation Brick

This video gives you a comprehensive understanding of Kerui’s mullite insulation bricks. First, its appearance and texture are shown up close. Then, you will walk into the production workshop and see how the workers operate. The entire process is a mature and reliable conventional process, focusing on quality control at every step.

Properties of Mullite Insulating Bricks

Mullite Insulating Bricks VS. Mullite Refractory Bricks

| Property | Mullite Insulation Brick | Mullite Refractory Brick |

| Additives | Hollow microspheres, perlite (reduce density) | Al₂O₃, ZrSiO₄, FeCr₂O₄ (enhance high-temp performance) |

| Porosity | High (50%-80%), porous | Low (≤20%), dense |

| Density | 0.55-1.1 g/cm³ (lightweight) | 2.6-2.7 g/cm³ (high density) |

| Refractoriness | 1600°C | 1680°C |

| Thermal Conductivity | 0.17-0.43 W/m·K (very low) | 1.5-2.5 W/m·K (relatively high) |

| Thermal Shock Resistance | Moderate (porous structure may crack) | Excellent (withstands rapid thermal cycling) |

| Advantages | • Energy-saving • Lightweight • Reduces load |

• High temp resistance • Corrosion resistance • Structural stability |

| Typical Applications | • Furnace insulation • Pipeline insulation |

• High-temp furnace linings (glass, cement) • Direct flame/melt contact |

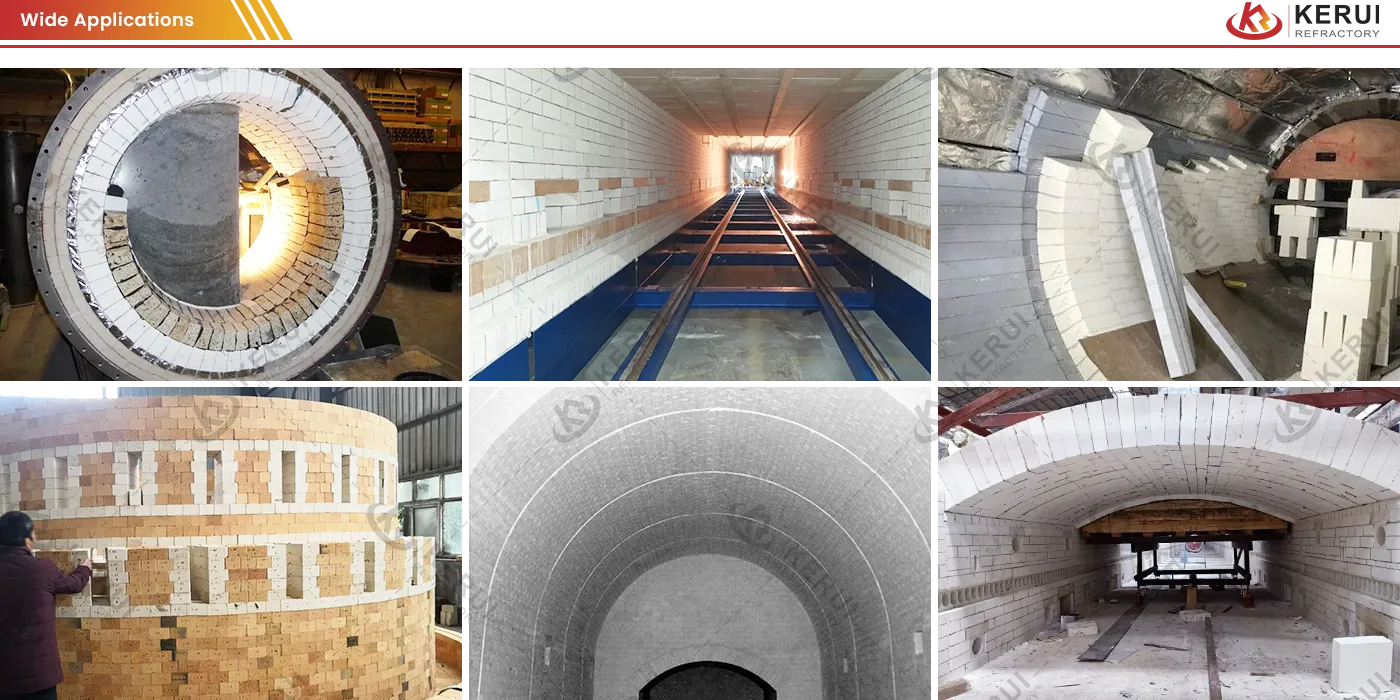

Industrial Implementation Scenarios of Kerui Mullite Bricks

Packaging Upgrade of Kerui Mullite Insulation Bricks

Kerui has upgraded the packaging of insulation bricks, and the main benefits are as follows:

- Prevents loosening and collapsing stacks: The reinforcement strips tightly secure the bricks. They reduce the risk of damage by preventing packaging loosening or stack collapses during transport vibrations and bumps.

- Suitable for long-distance transport: This is especially ideal for high-vibration scenarios like sea freight and railway shipping. It maintains packaging integrity.

- Reduces edge wear: Insulation brick edges are fragile. The reinforcement strips avoid damage from friction and impacts.

- Unitized organization: The secured packaging allows easier stacking. It saves storage and transportation space, lowering logistics costs.

- Customized package: We can customize the packaging logo and materials according to customer requirements.

Kerui Mullite Insultion Bricks is Trusted by Global Industry Leaders

Partners across 50+ countries, including RUSAL, CHALCO, ALBA, POSCO, and PSM, choose Kerui for reliable performance, demonstrating strong recognition and fostering long-term partnerships. View some videos on YouTube.

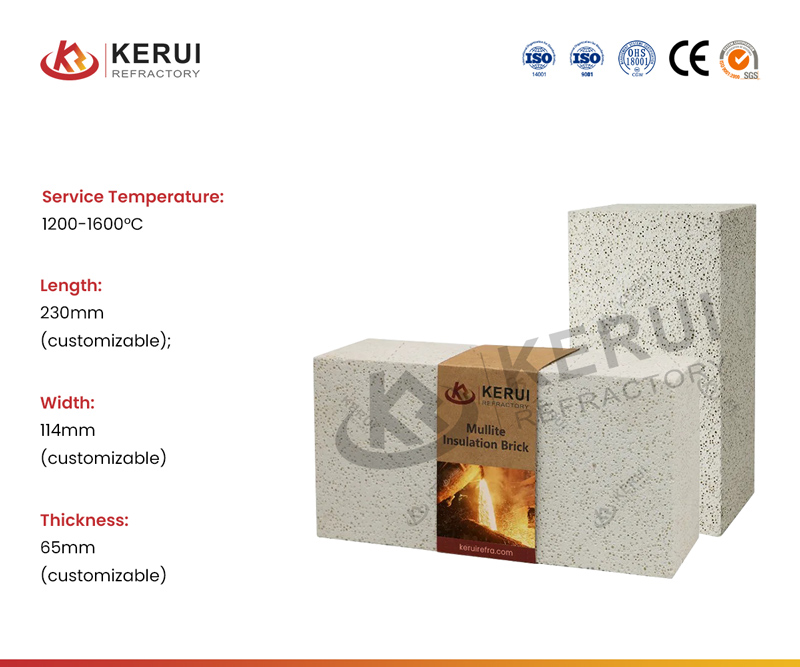

Specification Data of Kerui Mullite Bricks

Kerui Refractory offers four grades of mullite insulation bricks, including JM-23 (KR-23), JM-26 (KR-26), JM-28 (KR-28), and JM-30 (KR-30).

In addition, kerui refractory also provides B and C series insulation bricks. Please contact us for more details.

KR/JM23 Mullite Brick

| Item/Grade | KR-23 | |||

|---|---|---|---|---|

| Type | A | B | C | D |

| Al2O3, % | ≥42 | ≥42 | ≥45 | ≥48 |

| Fe2O3, % | ≤1.2 | ≤1.2 | ≤1.0 | ≤1.0 |

| Bulk Density, g/cm³ | 0.55 | 0.6 | 0.8 | 1.00 |

| Reheating Linear Change, % | ≤-0.5 | ≤-0.55 | ≤-0.4 | ≤-0.3 |

| Temperature*12h | 1230℃ | 1260℃ | 1300℃ | 1300℃ |

| Cold Crushing Strength, MPa | ≥1.2 | ≥1.5 | ≥2.3 | ≥3 |

| Thermal Conductivity 350℃, W/(m·K) | 0.17 | 0.19 | 0.24 | 0.31 |

KR/JM26 Mullite Brick

| Item/Grade | KR-26 | |||

|---|---|---|---|---|

| Type | A | B | C | D |

| Al2O3, % | ≥54 | ≥55 | ≥56 | ≥56 |

| Fe2O3, % | ≤0.9 | ≤0.9 | ≤1.0 | ≤1.0 |

| Bulk Density, g/cm³ | 0.7 | 0.8 | 0.9 | 1.0 |

| Reheating Linear Change, % | ≤-1 | ≤-0.65 | ≤-0.5 | ≤-0.5 |

| Temperature*12h | 1400℃ | |||

| Cold Crushing Strength, MPa | ≥2 | ≥2.3 | ≥2.8 | ≥3.2 |

| Thermal Conductivity 350℃, W/(m·K) | 0.21 | 0.25 | 0.3 | 0.32 |

KR/JM28 & KR/JM30 Mullite Brick

| Item/Grade | KR-28 | KR-30 | |||

|---|---|---|---|---|---|

| Type | A | B | C | A | B |

| Al2O3, % | ≥64 | ≥65 | ≥66 | ≥72 | ≥72 |

| Fe2O3, % | ≤0.75 | ≤0.65 | ≤0.65 | ≤0.55 | ≤0.55 |

| Bulk Density, g/cm³ | 0.8 | 0.9 | 1.0 | 1.0 | 1.1 |

| Reheating Linear Change, % | ≤-1 | ≤-0.8 | ≤-0.7 | ≤-0.9 | ≤-0.7 |

| Temperature*12h | 1500℃ | 1600℃ | |||

| Cold Crushing Strength, MPa | ≥2.3 | ≥2.8 | ≥3.3 | ≥3.0 | ≥3.5 |

| Thermal Conductivity 350℃, W/(m·K) | 0.28 | 0.32 | 0.34 | 0.4 | 0.43 |

Kerui Refractory is Your Ideal Expert

Kerui Refractory’s mullite insulation bricks are multifunctional. And they have a long lifespan. When you choose our products, you are not just investing in mullite insulation bricks, but also in quality assurance and peace of mind service. Kerui Refractory provides you with the most suitable insulation bricks and insulation solutions. Please send us your detailed requirements now.