K23 Insulating Firebrick

K23 insulating firebrick is a grade of mullite insulating brick. Its good features makes it to be used in furnace equipment to help improve the thermal efficiency of the equipment. As a manufacturer, Kerui provides standard bricks and customized bricks in various sizes to more than 1,000 customers globally.

- Free Sample:

- Available

- Document:

- Certificates Supporting

- Performance Test:

- Support

- Shipment:

- 7-35 working days

Basic Parameters of K23 Insulating Firebrick

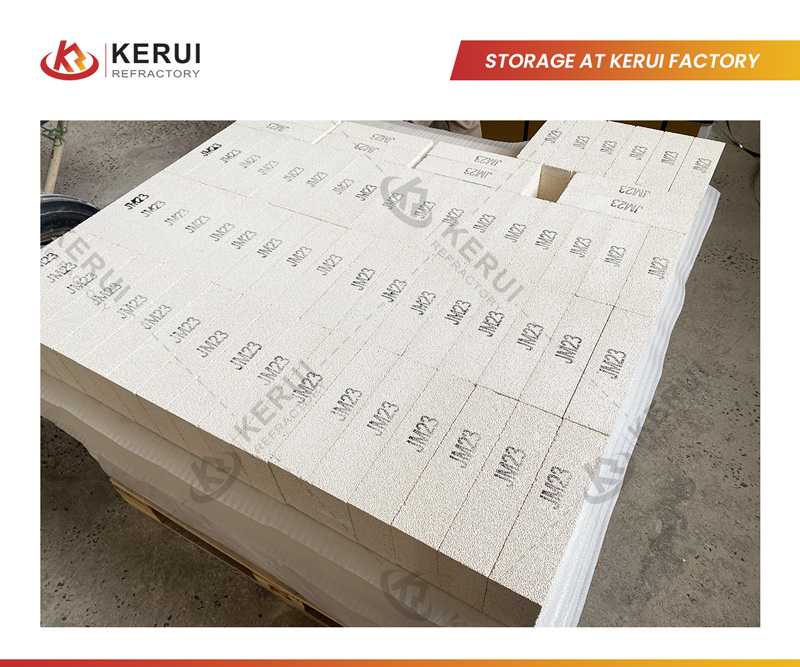

K23 insulation bricks is also called JM23 bricks, B5 bricks. Please see the parameters.

| Item/Grade | KR-23 | |||

|---|---|---|---|---|

| Type | A | B | C | D |

| Al2O3, % | ≥42 | ≥42 | ≥45 | ≥48 |

| Fe2O3, % | ≤1.2 | ≤1.2 | ≤1.0 | ≤1.0 |

| Bulk Density, g/cm³ | 0.55 | 0.6 | 0.8 | 1.00 |

| Reheating Linear Change, % | ≤-0.5 | ≤-0.55 | ≤-0.4 | ≤-0.3 |

| Temperature*12h | 1230℃ | 1260℃ | 1300℃ | 1300℃ |

| Cold Crushing Strength, MPa | ≥1.2 | ≥1.5 | ≥2.3 | ≥3 |

| Thermal Conductivity 350℃, W/(m·K) | 0.17 | 0.19 | 0.24 | 0.31 |

Shapes of K23 Soft Fire Brick

The appropriate brick shape improves construction efficiency, furnace thermal efficiency, and the service life of the furnace.

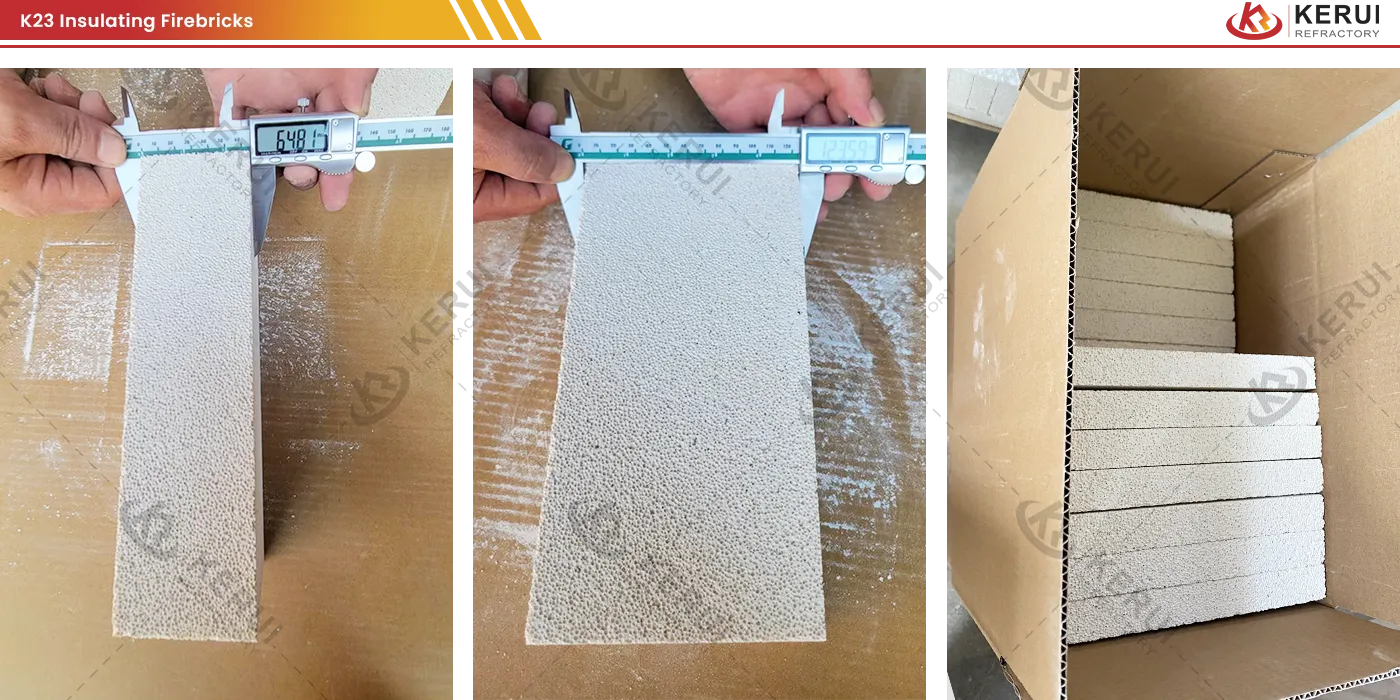

- For common insulating firebrick shapes, Kerui offers straight bricks 230*114*65mm/9″*4.5″*2.5″, arch bricks, wedge bricks, tapered brick, end brick, and so on.

- For custom-shaped bricks, Kerui can manufacture them according to the customer’s provided drawings and sizes.

Free Sample to Customers for Testing

When many customers purchase Kerui products for the first time, they often worry whether they are really suitable for their high-temperature kiln applications. In order to dispel their concerns, Kerui provide samples for customers to test and verify. 95% of customers fully recognize the high quality of Kerui products after receiving and trying them, and believe that they fully meet their needs, so they choose to continue to place orders and cooperate.

Quality Control of Kerui Insulating Fire Bricks K23

Strictly screen high-purity mullite, alumina and other raw materials to ensure stable chemical composition and low impurity content;

Optimize the particle structure through the awakening process, evenly distribute the particle grading, effectively reduce the porosity of the product, and improve the density and thermal stability.

Use a fully automatic batching system to accurately control the proportion of each raw material to ensure batch consistency;

Use efficient extrusion molding equipment to control the compaction degree and brick structure to ensure uniform brick size and reliable strength.

Equipped with two 168-meter large natural gas tunnel kilns, constant temperature firing and multi-stage temperature control;

Ensure that the product is fully sintered at high temperature, significantly improving thermal shock stability and anti-stripping performance.

Especially suitable for furnace parts with complex structures or high precision requirements.

Features of K23 Insulating Bricks

Package of K23 Insulating Bricks

Customized packaging: Kerui can also provide customized packaging according to customer requirements.

Kerui have our own physical and chemical laboratory to regularly test key properties of products such as volume density, compressive strength at room temperature, thermal conductivity, and maximum operating temperature according to standards;

Kerui can provide third-party test reports or product certificates according to customer requirements to ensure compliance with project bidding or export.

At the same time, Kerui have obtained ISO 14001 environmental management system certification, focusing on green manufacturing;

Many products have passed CE EU certification, meeting the requirements for export to the EU and other international markets.

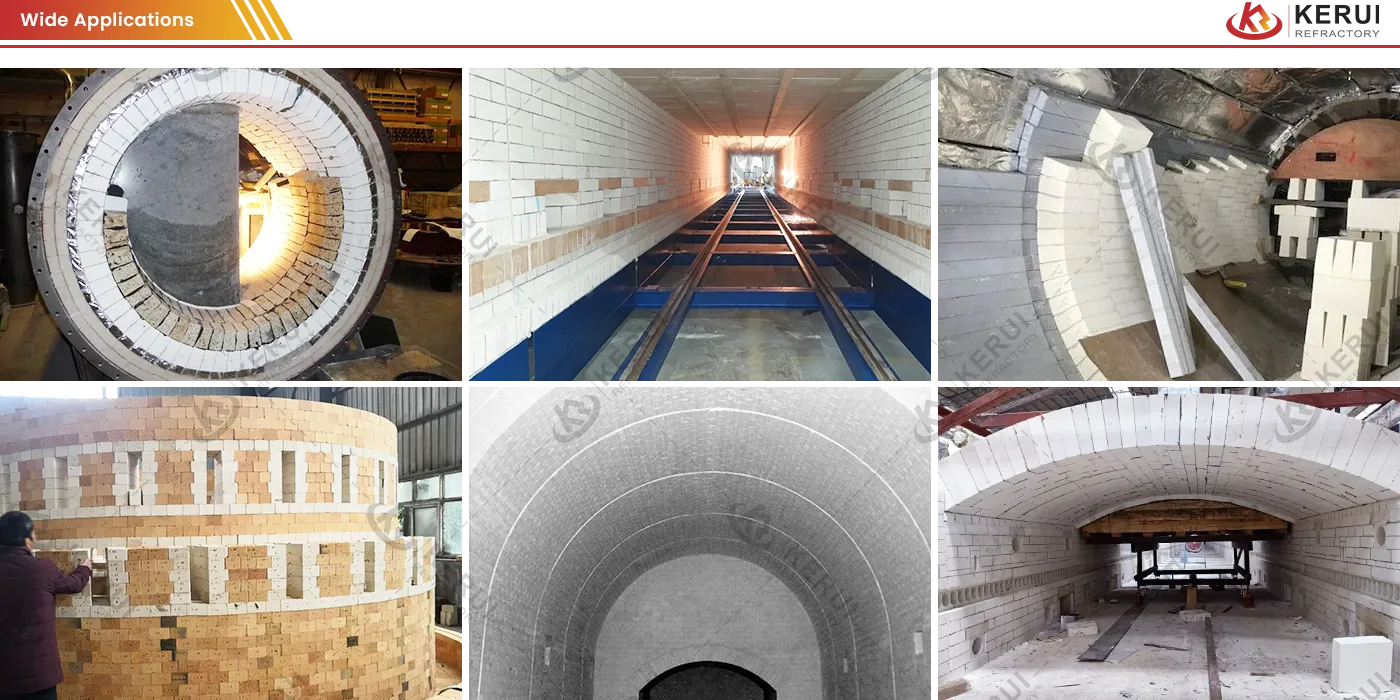

Application to Industrial Kilns and Furnaces

K23 firebrick is primarily used for the lining, roof, walls, bottom, and flue gas channels of high-temperature equipment.

- Glass Kilns: Glass melting furnaces, glass annealing kilns, etc.

- Metal Smelting Furnaces: Electric furnaces, heating furnaces, etc.

- Industrial Heating Furnaces: Petrochemical heating furnaces, hot air furnaces, etc.

- Heat Treatment Furnaces: Annealing furnaces, quenching furnaces, etc. View more details on Linkedin.

Kerui Mullite Insultion Bricks is Trusted by Global Industry Leaders

Kerui Refractory has garnered strong support from customers worldwide. These products have received positive feedback across various regions, reflecting Kerui’s commitment to excellence and customer satisfaction. View more pictures of cases on Pinterest.

- Exported to 20+ countries;

- 70% customer repurchase rate;

- 1,000+ global customers.

Contact Kerui Refractory

1-on-1 dedicated international sales manager consultation service;

Professional technical support service;

Mold and bricks customization service;

Quick delivery for in-stock items;

On-site construction technical guidance after sales.