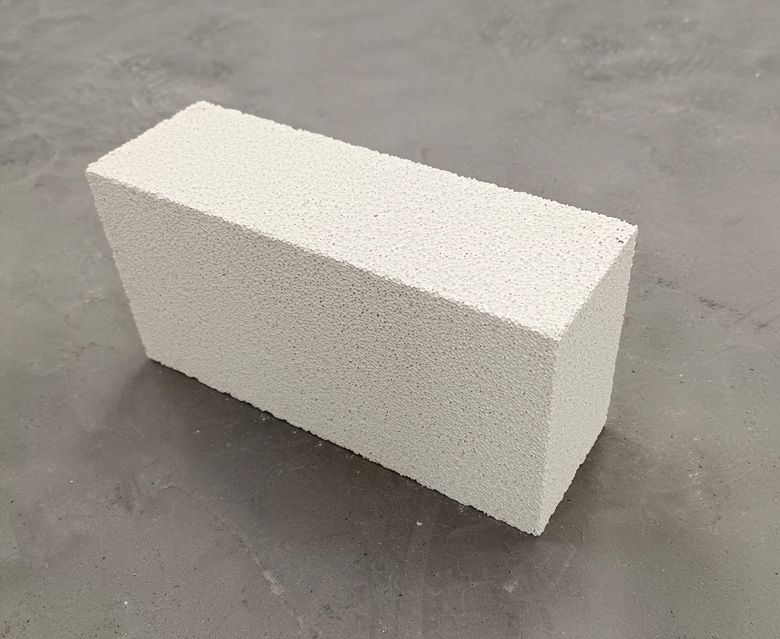

JM32 insulation brick is a type of mullite insulation brick. It offers excellent thermal insulation properties and high porosity. As a leading Chinese manufacturer with over 20 years of experience, Kerui provides a wide range of specifications and insulation solutions, including customized options to meet our customers’ unique needs.

- Al2O3: 77%;

- Fe2O3: 0.5%;

- Bulk Density: 1.35g/cm³;

- Reheating Linear Change: -1.5-0.5%;

- Cold Crushing Strength: 3.5MPa;

- Size: 230*114*65mm (standard)/And other sizes;

Technical Parameters of Kerui JM32 Insulation Bricks

| Item/Index | JM32 | |

|---|---|---|

| Al2O3 % | 77 | |

| Fe2O3 % | 0.5 | |

| Bulk Density (g/cm3) | 1.35 | |

| Reheating Linear Change (%) | -1.5-0.5 | |

| Temperature*12h (ºC) | 1650 | |

| Cold Crushing Strength (Mpa) | 3.5 | |

| Thermal Conductivity (w/m*k) | 200ºC | 0.56 |

| 350ºC | 0.6 | |

| 600ºC | 0.64 | |

Types of JM32 Insulation Fire Brick

| Types | Production | Features |

| Sintered Type | The primary raw material for sintered mullite insulating bricks is high-alumina bauxite, with small amounts of clay or raw alumina as a binder. It is formed and then sintered. | Mullite crystals; Relatively loose structure; Good thermal shock resistance; Good slag resistance; |

| Fused Type | Fused mullite bricks are made from high-alumina bauxite, industrial alumina, and refractory clay. Charcoal or coke fines are added as reducing agents. After shaping, they are produced using a reduction melting process. | Larger crystals; Compact structure; Better thermal shock resistance; Better slag resistance. |

Features of Kerui JM32 Insulation Fire Bricks

Mullite insulation bricks are made by using organic matter as a burnout material to increase the porosity of the refractory. They offer several advantages:

- Low bulk density;

- Low thermal conductivity;

- High temperature stability with minimal dimensional change;

- High compressive strength;

- Excellent thermal insulation;

- Direct contact with flame;

- Good corrosion resistance in various atmospheres;

- Good bonding with the furnace lining for extended service life;

- Environmentally friendly;

- Easy to process and can be shaped into various forms.

Size and Shapes of JM32 Bricks

Kerui offers a wide range of refractory products, including standard, semi-standard, special-shaped, and custom-shaped bricks. For more details, please contact us.

Common Applications of JM32 Insulation Bricks

JM32 insulation bricks are primarily used as insulation layers, furnace chambers, and flues in kilns for the following high-temperature industries:

- Metallurgy: Blast furnace hearths and bottoms, hot blast stove tops, ladle linings, heat treatment furnaces, etc.

- Ceramics: Ceramic kilns, etc.

- Glass: Glass furnace regenerators, sintering furnaces, etc.

- Petrochemical: Petroleum cracking furnaces, etc.

- Power: Boilers, incinerators, fluidized bed boilers, etc.

- Cement: Cement kilns, etc.

- Other industries: Chemical industry, etc.

Choose Kerui for JM32 Insulation Bricks

Choosing Kerui means choosing reliability, peace of mind, and worry-free service. Kerui has several key advantages:

Product Quality Assurance

Strict Quality Control System: Kerui has a comprehensive quality management system. The team rigorously tests and controls every step, from raw material procurement to product delivery.

Advanced Production Technology: Kerui uses advanced production processes and equipment to ensure the density, uniformity, and stability of its products.

Strong Technical Expertise

Professional R&D Team: Kerui boasts an experienced R&D team that continuously innovates and improves products to meet market demands.

Customization Services: Based on specific customer requirements, Kerui provides customized products and solutions.

Extensive Industry Experience

Years of Industry Experience: Kerui has 20+ years of experience and is professional in the processes and equipment requirements for high-temperature industries.

Successful Cases: Kerui has supplied 50+ well-known enterprises, including RUSAL, CHALCO, ALBA, POSCO, PSM, and others.

Comprehensive Service System

Professional Sales Team: Kerui’s sales team provides expert technical consulting and pre-sale and post-sale services.

Timely Logistics and Delivery: Kerui works with reliable logistics partners to ensure timely product delivery to customers.

Good Corporate Reputation

Integrity in Business: Kerui has always established long-term, stable partnerships with numerous customers..

Positive Reputation: Kerui enjoys a strong reputation in the industry, with customers highly praising its products and services.

See some videos about Kerui on Youtube.