The JM30 insulation brick has a higher alumina content compared to other bricks in the JM series. It is a new type of energy-saving refractory material that exhibits stable performance at high temperatures. Kerui has a well-established and advanced production line. This enables Kerui to offer a wide range of products with various specifications to customers.

- Al2O3: ≥72%;

- Bulk Density: 1.0-1.1g/cm³;

- Refractoriness Under Load: 1550ºC;

- Cold Crushing Strength: 3.0-3.5MPa;

- Size: 230*114*65mm (standard)/And other sizes;

Specifications of JM30 Insulation Brick

The JM30 insulation brick is a high-alumina refractory material with mullite (3Al₂O₃·2SiO₂) as the main crystalline phase. A small amount of organic material is added during the production process, and after firing, this insulation fire brick forms uniform porosity. Please refer to the detailed parameters.

| Item/Grade | KR-30 | |

|---|---|---|

| Type | A | B |

| Al2O3, % | ≥72 | ≥72 |

| Fe2O3, % | ≤0.55 | ≤0.55 |

| Bulk Density, g/cm³ | 1.0 | 1.1 |

| Reheating Linear Change, % | ≤-0.9 | ≤-0.7 |

| Temperature*12h | 1600℃ | |

| Cold Crushing Strength, MPa | ≥3.0 | ≥3.5 |

| Thermal Conductivity 350℃, W/(m·K) | 0.4 | 0.43 |

Choose Kerui JM30 Insulation Bricks

- Can Be Directly Exposed to Flame;

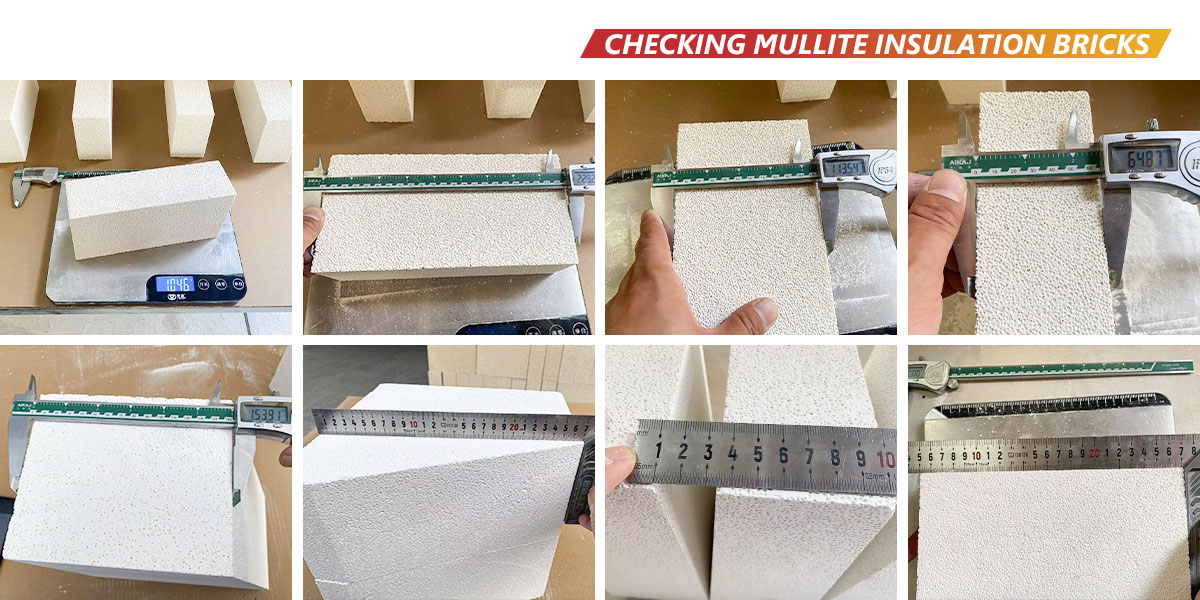

- Precise Appearance and Dimensions, Accelerating Construction Speed;

- Customizable, Reducing the Number of Bricks and Joints.

- High-temperature Resistance;

- Low Thermal Conductivity, Significant Energy-Saving Effect;

- High Strength;

- Resistant to Molten Liquid Erosion;

- Good Thermal Stability;

- Complies with Standards;

Good Quality Control of JM30 Insulating Brick

- Select High-Quality Mullite;

- High-Temperature Firing Ensures Structural Stability of the Mullite Insulation Fire Bricks;

- Comprehensive Material and Physical Testing;

- Third-Party Testing Supported;

- Complete Pallet/Wooden Box Packaging;

- Factory Visit Support for Customers;

Global Customers of Kerui JM30 Bricks

Kerui customer base includes countries such as Indonesia, Morocco, Iraq, Brazil, and so on. With a commitment to advanced production technology, quality control, and customer-oriented service, Kerui continues to be a preferred supplier of high-performance insulating bricks in international markets. 70% of customers repurchased Kerui products.

Kerui is Your Top Choice

- Powerful Factory Production Capacity;

- Factory Direct Prices;

- Automated Production Workshops Provide High-Quality Products for Customers;

- Professional Testing Equipment Ensures Product Quality;

- Optimized Cost-Performance Refractory Materials Configured Based on Customer Needs;

- ISO 9001, ISO 14001, and Other Certifications;

- Thoughtful After-Sales Service.

Fields of Application for JM30 Bricks

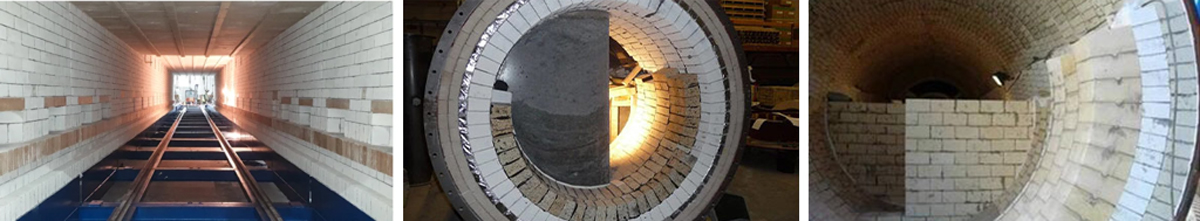

JM30 Insulating Bricks are primarily used in insulation layers and linings to reduce heat loss and improve energy efficiency. They are commonly applied in furnace tops, furnace walls, drying areas, and preheating zones, among others.

- Metallurgical Industry: Metallurgical hot blast stoves, blast furnaces, metal melting furnaces, hot blast stoves, etc.

- Petrochemical Industry: Petroleum cracking furnaces, ethylene cracking furnaces, tubular heating furnaces, gas generators, etc.

- Ceramic Industry: Ceramic roller kilns, tunnel kilns, sintering kilns, high-temperature shuttle kilns, push-plate kilns, and other equipment.

- Electric Porcelain Kilns: Electric porcelain shuttle kilns, electric porcelain drawer kilns, etc.

- Glass Industry: Glass crucible kilns, glass melting furnace regenerator chambers, etc.

- Other Industrial Furnaces: Various other high-temperature industrial furnaces.

Contact Kerui Refractory

Kerui has established long-term relationships with numerous customers globally. We provide tailored solutions to meet the specific needs of each customer. Our commitment to quality, advanced production technology, and customer-focused service ensures that we continue to be a preferred supplier of high-performance insulating bricks. See some updates on Linkedin.