Insulating fire bricks are the lightweight brick used in high-temperature kilns and equipment. They have low thermal conductivity. Kerui offers a variety of types and custom bricks. Additionally, we provide other refractory materials that complement these bricks, such as castables. Therefore, please send us your construction or repair plans. We can offer matching refractory solutions and materials based on your needs.

Different Types of Kerui Insulating Fire Bricks

Based on varying operating temperatures and environments, we primarily offer the following types and grades of insulating firebricks. They can be used at temperatures below 1800 degrees Celsius.

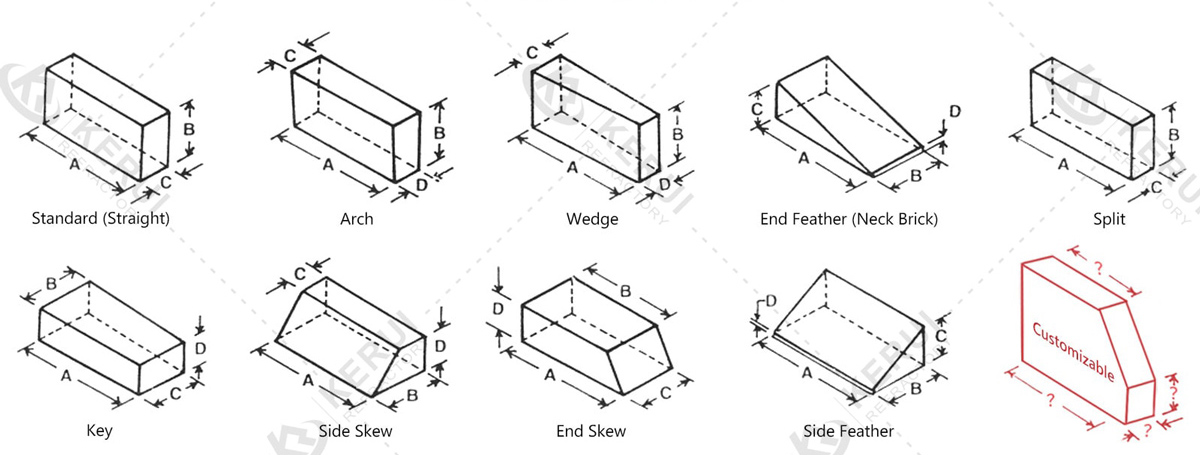

Different Shapes of Insulating Fire Brick for Sale

The standard dimensions are: 230*114*65mm. We offer the following commonly used shapes of insulation bricks for various high-temperature kilns:

Standard (straight), arch, wedge, key, side skew, end skew, side feather, end feather (neck brick), split, bonder, circle, dome, tile, internal plinth return, bullnose stop, birthmouth brick, external plinth, internal plinth, cant stop, double cant, external angle, bullnose header, double bullnose, radial stretcher, etc.

Note: Kerui factory has a large stock of standard-grade straights.

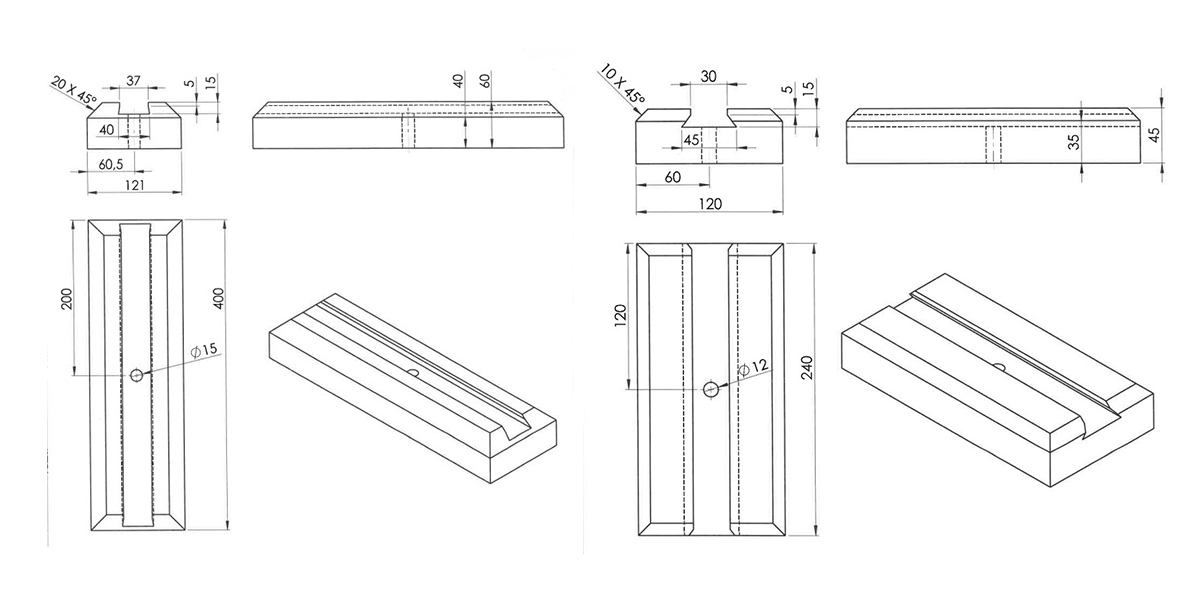

Custom Shaped Insulating Fire Bricks

Kerui supports the customization of various shaped insulating bricks to meet the specific needs of different industrial applications. Whether you require unique dimensions, special designs, or tailored performance characteristics, we are fully equipped to deliver precise solutions. Please send us the technical drawings or design specifications, and our engineering team will promptly review them and confirm the mold details with you before proceeding to production. This ensures accuracy, efficiency, and a seamless customization process.

Advantages of Kerui IFB Bricks

Good Features:

- Lightweight;

- Low thermal conductivity, energy-saving;

- Excellent thermal shock resistance;

- Outstanding strength;

Excellent Quality:

- Made from high-quality raw materials;

- Precise dimensions;

- ISO certified;

- Subjected to strict quality inspections;

Comprehensive Services:

- Factory visits and inspections supported;

- Beautiful and high-quality packaging;

- Fast shipping within 15-30 working days;

- Customization services available.

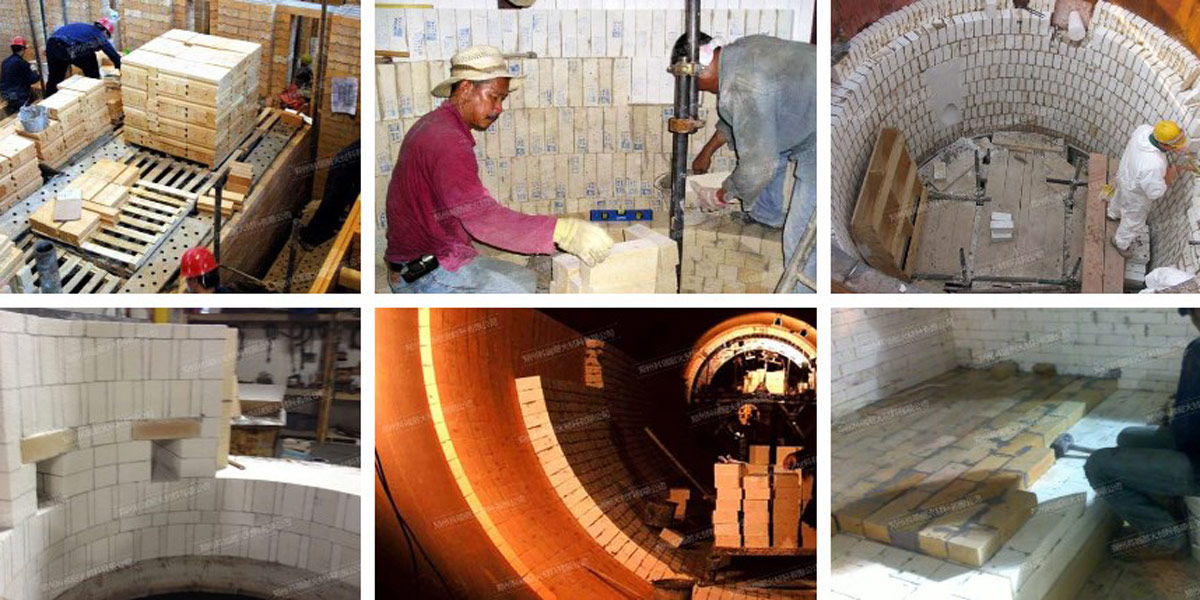

Applications of IFB Insulation Fire Bricks

Lightweight insulation fire brickss are primarily used in hot face applications in the following industries: glass, ceramics, electrolytic aluminum, steel and aluminum, non-ferrous metals, power generation, petroleum, and so on.

These bricks are used for kilns, lining furnaces, reactors, and other carriers for holding and transporting hot mediums. View Kerui Linkedin to see some site applications.

In conclusion, Kerui’s insulating fire bricks offer reliable performance, energy efficiency, and versatility for a wide range of high-temperature applications. Whether you are planning a new build or repairing existing equipment, our team is ready to support you with customized brick options as well as matching refractory materials like castables. To ensure optimal results, please feel free to share your construction or repair plans so that we can provide tailored refractory solutions that meet your exact requirements.