sHigh-purity graphite crucible is characterized by high refractoriness. Kerui Refractory provides crucibles in various sizes, materials, and densities according to customer requirements. The Kerui factory boasts large production capacity and customization capabilities, along with offering factory graphite crucible prices.

- Max. working Temperature: 900-1800ºC;

- Refractoriness Under Load: 2000ºC;

- Carbon Content: ≥99.95%;

- Bulk Density: ≥1.75-1.85g/cm³;

- Apparent Porosity: ≥13-17%%;

- Outer diameter: 142-1050mm/Customized;

- Inner diameter: 110-930mm/Customized;

- Overall height: 180-1320mm/Customized;

- Bottom outer diameter: 90-550mm/Customized;

Advantages of Kerui Graphite Crucibles

High-purity graphite crucibles are high-temperature containers made from high-purity graphite materials. They offer the following advantages:

- High Purity: The high purity of the graphite results in excellent performance.

- High-Temperature Resistance: The graphite crucible has an extremely high melting point and exhibits good stability when used at elevated temperatures.

- Excellent Thermal Conductivity: Their superior thermal conductivity helps ensure uniform heating.

- Good Thermal Shock Resistance: This kiln shelf can withstand rapid changes in temperature without damage.

- High Density: They possess high hardness and mechanical strength, making them less prone to breakage.

- Strong Machinability: The graphite crucible can be easily machined into any shape and size.

- No Mold Costs: Compared to crucibles made from other materials, these crucibles reduce mold expenses.

- Long Service Life: With proper use and maintenance, they have a longer lifespan than crucibles made from other materials.

Applications of Graphitized Graphite Crucibles

- Metallurgical Industry: The application of this product is for melting precious metals, non-ferrous metals, alloys, and more.

- Chemical Industry: The uses of this product in high-temperature synthesis, crystal growth, chemical reaction vessels, and other applications.

- Electronics Industry: The application of these crucibles is in the preparation of semiconductor materials.

- Laboratories: Their uses are in high-temperature experiments, sample melting, and other laboratory procedures.

- Additionally, these products have wide applications in the energy sector and photovoltaic industry.

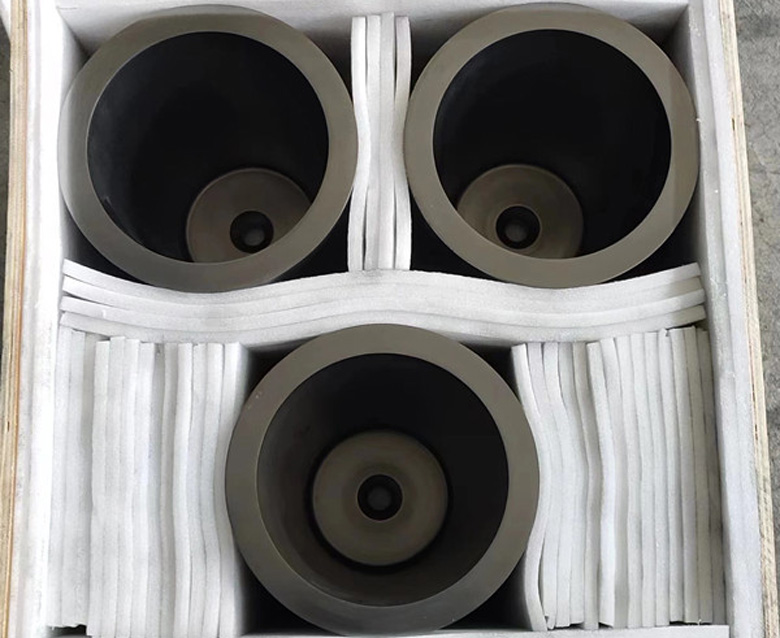

Kerui Graphite Crucibles Shipped to Africa

Over 50 customers have purchased Kerui graphite crucibles. This time, a customer from Africa customized graphite crucibles from us.

- Based on his requirements, we provided technical parameters and design drawings. The satisfaction rate of customers was very high.

- After confirming the collaboration, our factory began production.

- Once production was completed, our quality inspection team tested the products. After passing the inspection, this batch of crucibles and SIC beam was shipped to Africa.

Considerations for Purchasing and Using Graphite Crucible

- Clarify Technical Parameters: Clearly define the composition, dimensions, density, and other technical parameters of the crucible.

- Suitable Applications: These crucibles are suitable for melting non-ferrous metals (gold, silver, copper, aluminum, lead, zinc), steel, alloys, and ceramic materials.

- Inappropriate Applications: These graphite crucibles are not suitable for melting chemical products such as lead and cadmium.

- Follow Usage Guidelines: When using the crucibles, adhere to the established usage guidelines.

Kerui is Your Graphite Crucible Manufacturer

high-purity graphite crucibles represent a pivotal advancement in the field of high-temperature processing and material handling. Their exceptional properties make them indispensable in various industrial applications. Kerui Refractory, as the graphite crucible manufacturers, always provides a wide range of crucibles tailored to customer specifications. High-purity graphite crucibles offer unparalleled performance and versatility across multiple industries. This product positions them as a leading choice for applications requiring precision and reliability. View more news about Kerui on Linkedin.