Forsterite brick is a kind of alkaline material. It consists of magnesium oxide and silicon dioxide. The main content is forsterite which has a high melting point. It can replace the magnesia chrome brick used for the linings of furnaces. Kerui can provide high-quality bricks that have good corrosion resistance and strength under high temperatures.

- Mgo: 50-60%;

- Bulk Density: 2.65-2.7g/cm³;

- Refractoriness Under Load: 1620-1650ºC;

- Cold Crushing Strength: 35MPa;

- Size: 230*114*65mm (standard)/And other sizes;

Sizes of Forsterite Brick

The standard size of brick: 230*114*65mm.

We have various sizes of forsterite brick including knife brick, universal arc brick, runner brick, etc. Besides, we also have forsterite checker bricks because they are usually used for glass furnace chambers.

Features of Fireproof Forsterite Brick

- Good Corrosion Resistance: Fireproof forsterite brick is an alkaline brick that has good alkaline resistance. So it will not eroded by alkaline slag. Moreover, fireproof brick can resist sulfate corrosion. In this situation, it usually replaces magnesia chrome brick in glass kilns because it can keep a stable state and resist abrasion.

- Low Thermal Conductivity: Fireproof forsterite brick has low thermal conductivity. It means that the energy can be effectively utilized. Besides, it can reduce heat transfer to sustain the high-temperature environment in equipment. In this situation, users can greatly save economic costs.

- High Under Load Temperature: The high under load temperature contributes to sustaining a steady structure of brick. Fireproof forsterite bricks can resist thermal shock and can keep a stable volume of high-temperature equipment.

- Environment-friendly: Compared with magnesia chrome brick, fireproof forsterite brick will not produce poisonous material. It is a green refractory material that is innocuous to the environment. It can be widely used for high-temperature equipment under the improvement of environmental awareness.

Usages of Forsterite Fire Brick

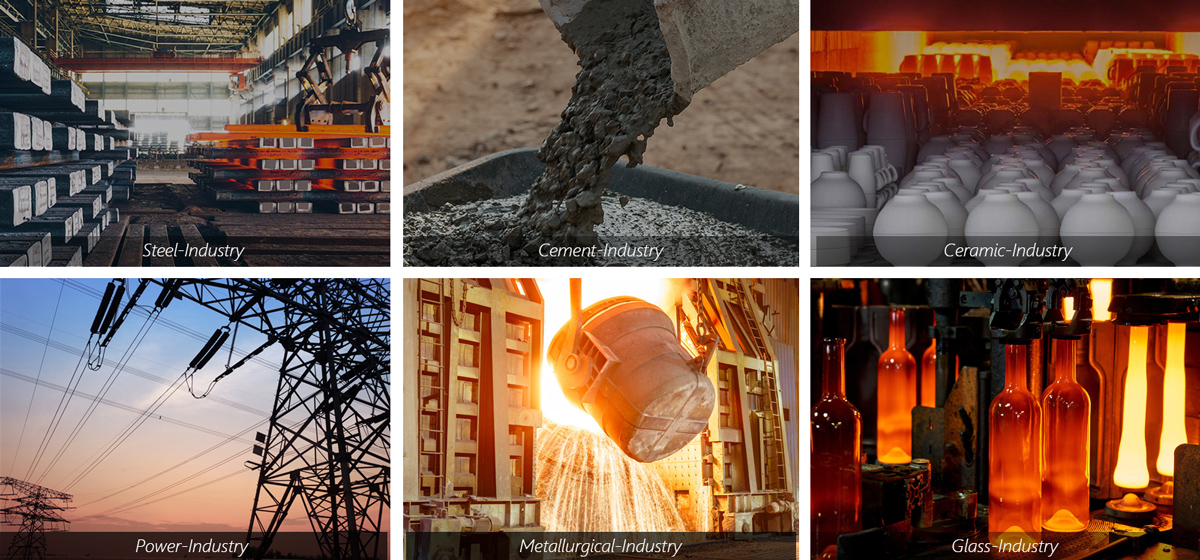

Forsterite fire brick is mainly used for the linings of nonferrous melting furnaces, glass kiln chambers, steel-making open hearth furnaces, ladles, and the linings of rotary kilns. It also can used for patching materials, tundish slag-stopping walls, etc.

Kerui Forsterite Refractory Bricks Shipped to 20+ Countries

Kerui forsterite bricks are shipped to more than 20 countries. Our cooperation process with them mainly includes:

- Forsterite brick solution consultation;

- Kiln location technical support;

- Customized production;

- Product quality inspection and strict packaging;

- Fast delivery;

- Logistics timely update of fire bricks;

- Cargo inspection;

- After-sales guarantee;

Kerui Has A Strict Production Process

Our products have inspection certificates from international institutions. Kerui will ensure every production process has a monitoring system to produce high-quality refractory forsterite brick. We have digital intelligence equipment to control the raw materials ratios. Before delivery, we will inspect the brick again to ensure customers get qualified products.

Service of Kerui

Kerui sells many refractory materials so customers can purchase all the products at once. If you don’t know which refractory products is optimal, we have professional technicians to solve your problems. We also can guide your construction. Kerui is glad that more customers can cooperate with us. Contact us through WhatsApp.