Electric arc furnace is mainly used in metallurgy, chemical, and building material industries. Refractories for electric arc furnaces need to select high refractoriness, good thermal shock resistance, and great extreme temperature change resistance.

Refractories for Electric Arc Furnaces

The top EAF bricks usually uses high alumina bricks, magnesia bricks, and magnesia chrome bricks. They have high refractoriness, high thermal shock resistance, and good chemical stability. So they can resist the chemical gas that comes from the body of the furnace.

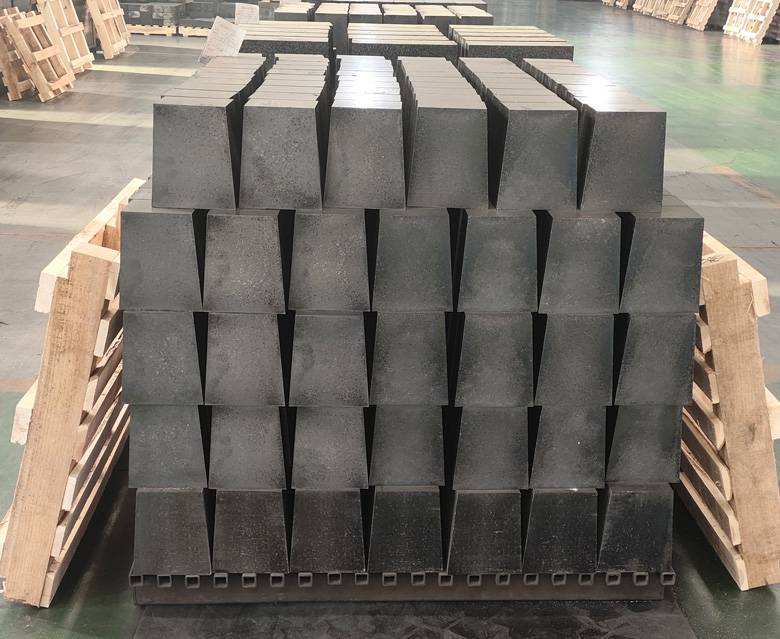

The body of electric arc furnaces usually uses magnesia bricks, magnesia carbon bricks, and silica bricks. The refractory lining of electric arc furnaces usually needs to resist chemical slag in a high-temperature environment. In this situation, the lining of the furnace easily cracks or peels. So the refractory bricks for linings mainly select a steady chemical structure and good resistance to extreme temperature change.

The bottom of the electric arc furnace needs to resist chemical slag erosion. So it usually uses magnesia bricks, magnesia carbon bricks, and magnesia chrome bricks.

Abundant Expert Experience

Kerui has more than 15 years of experience in the export business. We have various experiences to solve customers’ questions from different cases. Kerui is devoted to helping customers find the most suitable high-temperature equipment. And we know the many import policies of different countries.

High-quality Refractory Products

Kerui has high-precision instruments to control the quality of refractory products. In the production lines, we have quality inspection personnel to ensure the products are manufactured. Through the feedback from customers, we constantly improve the ability of our refractory materials.

Introduction of Electric Arc Furnaces

An electric arc furnace has three parts: the top of furnace, the body of furnace, and the bottom of furnace. The top of furnace is mainly used to reduce heat transfer and prevent raw materials pollute the environment. The body of furnace is the working parts. The bottom part carries slag and liquid steel.