Dense castable refractory has good construction performance and high strength mechanical properties. The material typically has a bulk density greater than 2150 kg/m³. At high temperatures, it exhibits good resistance to thermal shock and high abrasion resistance. It is widely used in high-temperature furnace linings and prefabricated components.

- Bulk Density: 0.8-3.2g/cm³;

- Service Temperature: 1300-1790ºC;

- Cold Crushing Strength: 4-95MPa;

- Compressive Strength: 6-100MPa;

Kinds of Dense Castable Refractory

Composition of Dense Castable Refractory

Dense castable is mainly composed of 70-80% aggregates, 10-20% fillers, and 5-10% binders.

- Aggregates mainly include ceramic fiber cotton, corundum, zircon, chromite, white corundum, mullite, etc. These materials affect the physical and chemical properties of the castable.

- Fillers mainly include cement, lime, silicates, etc. These fillers can improve the density, strength, flowability, and workability of this castable.

- Binders mainly include water, gel materials, other chemical binders, etc. These binders can adjust the durability and setting time of the castable.

Key Advantages of Dense Castable

- High refractoriness: Dense refractory castable can be suitable for various high-temperature environments.

- Low thermal conductivity: This castable has low density and thermal conductivity. Therefore, it helps reduce heat loss in high-temperature environments. However, its insulation effect is not as good as that of lightweight castable.

- Strong thermal shock resistance: The combination of refractory aggregates makes the castable stable against thermal shock.

- High mechanical strength: The dense structure and composition make the castable have good mechanical resistance, such as good bending resistance, strong compressive strength, and strong wear resistance.

- Easy construction: Due to its amorphous nature and binders, this material can be quickly constructed in any complex shape scenario.

Multiple Usages of Dense Refractory Castable

Due to its excellent properties, this refractory castable is suitable for various key industries, including steel metallurgy, electricity, petroleum, chemical industry, etc.

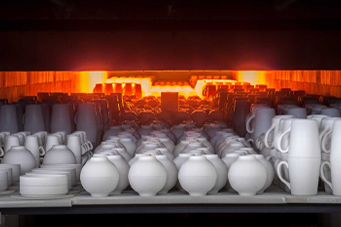

High-temperature kiln linings or insulating linings

It is suitable for making many high-temperature kiln linings and insulating linings, such as electric furnaces, ladles, heating furnaces, annealing furnaces, blast furnaces, ladle furnaces, melting furnaces, boilers, silicate kilns, incinerators, etc.

Other high-temperature device locations

Additionally, it is also used in the following areas: around high-temperature pipelines, around boiler tubes, observation holes, shaped prefabricated components, external refining device components, steel ladle nozzles, ladle refining package covers, high-temperature burners, blast furnace iron trough covers, burner blocks, troughs, etc.

Repair sites

It is also suitable for repairing linings and other severely worn parts. View some YouTube videos to see applications.