Corundum refractory castable is a high-performance unshaped refractory material mainly made of corundum and super alumina clinker. This material features high refractoriness and strength. It is suitable for high-temperature furnace linings, nozzles, spray guns, furnace covers, and so on.

- Al2O3: ≥85%;

- SiO2: ≥2%;

- Maximum Service Temperature: 1650-1700ºC;

- Cold Compressive Strength: 80-100Mpa (110ºC*24h);

- Packaging: 25kg bag/1 ton bag/25kg barrel;

Basic Parameters of Corundum Refractory Castable

| Item | G-17 | G-18S | G-18 | |

|---|---|---|---|---|

| Maximum service temperature,℃ | 1650 | 1650 | 1700 | |

| Al2O3 ,% | ≥85 | ≥90 | ≥93 | |

| SiO₂,% | 8 | 4 | 2 | |

| B.D After Drying at 110℃,g/cm³ | 2.9 | 3 | 3 | |

| Cold Bending Strength,Mpa | 110℃*24h | 9 | 12 | 14 |

| Cold Compressive Strength,Mpa | 110℃*24h | 80 | 90 | 100 |

| Linear Change Rate After Burning PLC,% | 1100℃*3h | ±0.3 | ±0.3 | ±0.2 |

| 1500℃*3h | ±0.6 | ±0.6 | ±0.5 | |

| Construction Reference Water Consumption,% | 4.5-5.5 | 5-6 | 5.5-6.5 | |

Introduction of Corundum Castable

The main components of Kerui corundum refractory castable are high-quality aggregates, powders, and binders. These components have different characteristics.

-

Aggregates and Powders

The high-quality aggregates and powders are mainly fused white corundum (plate-shaped and dense) and super alumina clinker. These raw materials have different particle sizes, high melting points, strength, and abrasion resistance. They enhance the physical and chemical properties of the castable.

-

Binders

The binders are mainly pure calcium aluminate cement, phosphates, water glass, and other binders. These raw materials bind the aggregates and powders together. They not only help improve the workability of the castable but also enhance its strength and durability.

Core Advantages of Kerui Corundum Refractory Castable

- High-temperature resistance: Corundum castable can be used at temperatures as high as 1700 degrees Celsius. It has extremely high refractoriness.

- Strong thermal shock resistance: Its permanent linear change is 0.6% at temperatures between 1100-1500 degrees Celsius. Therefore, it can maintain a stable structure at high temperatures without spalling. To improve thermal shock resistance, partners could choose the castable with mullite.

- Slag corrosion resistance: It has resistance to chemical corrosion by slag. It exhibits good corrosion resistance to acidic media. Additionally, it also has some resistance to alkaline media and reducing gases (H2, CO).

- High wear resistance: Its wear resistance is higher than that of high alumina castable. To enhance thermal shock resistance, partners could choose the castable with steel fiber.

- Ease of construction: Simply add water to the castable, mix well, and it is ready for use. Its shape can be adjusted according to construction requirements. The entire construction process is simple and fast.

Applications of Corundum Refractory Castable

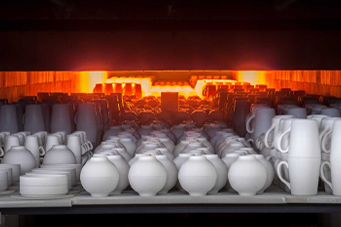

The applications of corundum castable are extensive, such as furnace lining casting, prefabricated parts, high-wear areas, and so on. Many high-temperature furnaces choose it as lining and repair materials, such as electric furnaces, blast furnaces, boilers, rotary kilns, hot blast stoves, heating furnaces, cement kilns, ceramic kilns, circulating fluidized bed boilers, synthetic ammonia processing equipment, and so on.

The application of corundum castable is mainly in the following areas: steel & iron furnace, arc furnace roof triangle area, prefabricated parts, water-cooled equipment for electric furnaces, horizontal steel outlet, lining, induction furnace nozzle, non-ferrous metal smelting furnace, vacuum degassing equipment for casting steel, gun lining, LF furnace cover, cracking reactor, cyclone separator, separator, flue, and so on.

Contact Us

If you have needs for corundum castables, please send us your detailed requirements immediately. As a manufacturer, we provide you with suitable and high-quality castables. If you wanna see more information about us, follow our Linkedin.