Checker brick is a kind of refractory brick that can withstand 500-1780℃. Checker refractory bricks are used as the lattice body of the regenerator in regenerative industrial furnaces. They are mainly used for energy storage and heat exchange. It can be used in hot blast stoves, glass kilns, and regenerators of coke ovens. Kerui offers different materials of this brick, like fireclay, high alumina, etc. More than 50 customers has applied Kerui bricks and have good feedback.

- Types: Clay, High-alumina, Mullite, Silica, Sillimanite, etc;

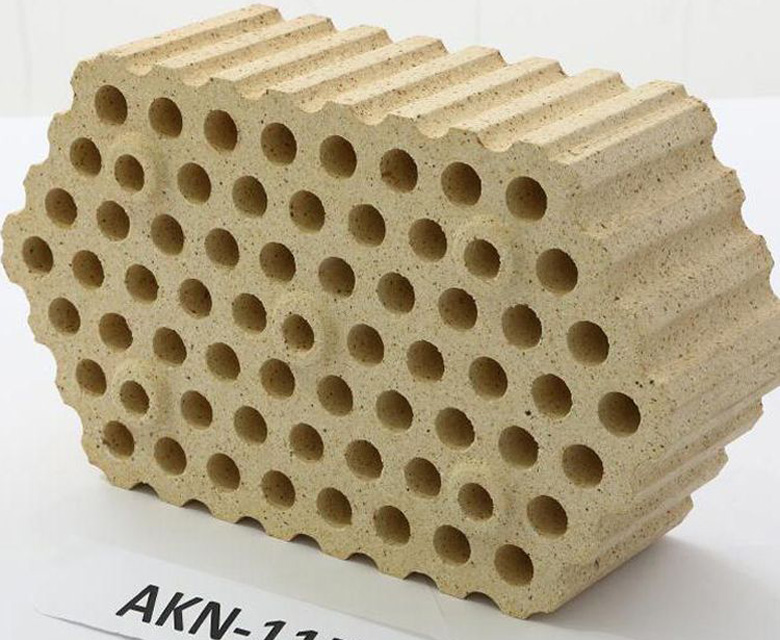

- Holes: 7/19/31/37/65/others;

- Delivery: 15-30 Working Days;

- Price: Low Ex-factory Price;

Types of Checker Brick

According to the numbers of holes, chequer bricks have the following types:

- 7-hole bricks;

- 19-hole bricks;

- 31-hole brick;

- 37-hole bricks.

According to the components, chequer bricks have several types:

- Clay checker bricks;

- High-alumina checker bricks;

- Mullite checker bricks;

- Silica checker bricks;

- Sillimanite bricks;

Other Related Refractory Bricks

Characteristics of Chequer Bricks

Strong Heat Exchange Capacity

This kind of refractory bricks China has a strong heat exchange capacity. This means that it has good thermal conductivity. When it is used for the regenerator of coke ovens, it contributes to rapidly making cold air turn into hot air.

Large Heat Storage Area

Chequer bricks have a lot of holes. These holes increase the contact area between bricks and hot air. So they can rapidly store the heat and transfer the heat. In a regenerative chamber, chequer brick has a small resistance force that can smooth ventilation.

Good Creep Resistance

Good creep resistance contributes to keeping a stable volume of high-temperature equipment in high-temperature situations. Besides, these bricks usually are hexagons. It can greatly increase the stability of checker bricks.

Applications of Checker Brick

Chequer bricks are usually used in hot blast stoves, glass kilns, regenerators of coke ovens, electric arc furnaces, induction furnaces, AOD furnaces, VOD furnaces, thermal technology equipment, etc.

It is worth to noting that it usually uses clay checker brisks in hot blast stoves, when the hot air is less than 900℃. When the hot air is more than 900℃, it usually uses high-alumina checker brick, mullite checker brick, silica checker brick, and sillimanite refractory bricks.

Choose Kerui to Get Checker Bricks

Kerui will provide high-quality checker bricks to customers. We have a strict quality control center and technological lab to develop better refractory materials. Moreover, our service team will put themselves in the customers’ position to offer the best scheme for customers. If you need, you can enjoy the turnkey service in Kerui. View more videos on Kerui Youtube.