Ceramic fibre blanket 25mm is widely used and has unique advantages in the field of industrial thermal insulation. It is widely used in industrial furnace linings, pipelines, and other applications. As the source factory, Kerui provides this product and related high-efficiency insulation solutions to over 1,000 customers worldwide.

- Classification Temperature: 1050-1430ºC/1922-2606°F;

- Bulk Density: 96-160kg/m³; 5-10lbs/cf;

- Hot Length: 7200/3600mm/Customizable;

- Hot Width: 600/610/1220mm/Customizable;

- Thickness: 25mm or 1′/Customizable;

- Document: MSDS supporting;

- Certificate: ISO9001/ISO14001/OHSAS18001/CE/SGS;

- Shipment: 7-15 working days;

- Source: Factory-direct manufacturer from China;

- Inventory: Large quantities of stock;

Technical Parameters of Ceramic Fibre Blanket 25mm

| Item | Common Type | Standard Type | High Purity Type | High Alumina Type | Zirconium Containing Type |

|---|---|---|---|---|---|

| Classification Temperature, ℃ | 1050 | 1260 | 1260 | 1350 | 1430 |

| Service Temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Bulk & Density, kg/m³ | 96-128 | 96-128 | 96-128 | 128-160 | 128-160 |

| Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) | -3 (1250℃) | -3 (1350℃) |

| Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) 0.22 (1000℃) | 0.132 (600℃) 0.22 (1000℃) | 0.76 (800℃) 0.20 (1000℃) |

| Strength of Extension, Mpa | 0.08-0.12 | ||||

| Al2O3, % | 44 | 46 | 47-49 | 52-55 | 39-40 |

| Al2O3+SiO2, % | 96 | 97 | 99 | 99 | - |

| Al2O3+SiO2+ZrO2, % | - | - | - | - | 99 |

| ZrO2, % | - | - | - | - | 15~17 |

| Fe2O3, % | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

| Size, mm | Standard Size: 7200/3600*610/1220*6-60; Customized Sizes | ||||

- Excellent value and basic insulation: The Common Type (1050°C) is ideal for insulating boilers, pipelines, and medium- and low-temperature thermal equipment.

- A versatile choice for industrial furnaces: The Standard Type (1260°C ceramic fiber blanket) and High Purity Type (1260°C) are the most widely used options. They significantly improve the heating and cooling speeds and efficiency of equipment like heat treatment furnaces and forging furnaces.

- For higher temperatures and harsher environments: The High Alumina Type (1350°C) provides enhanced resistance to high temperatures and reducing atmospheres. It is a suitable upgrade for high-temperature applications such as ladle covers and petrochemical cracking furnaces.

- The Zirconium Containing Type (1430°C) is our top-of-the-line product for the industry’s highest challenges. It’s the ideal solution for ultra-high-temperature applications, including aluminum melting furnaces, brazing furnaces, and ceramic sintering furnaces.

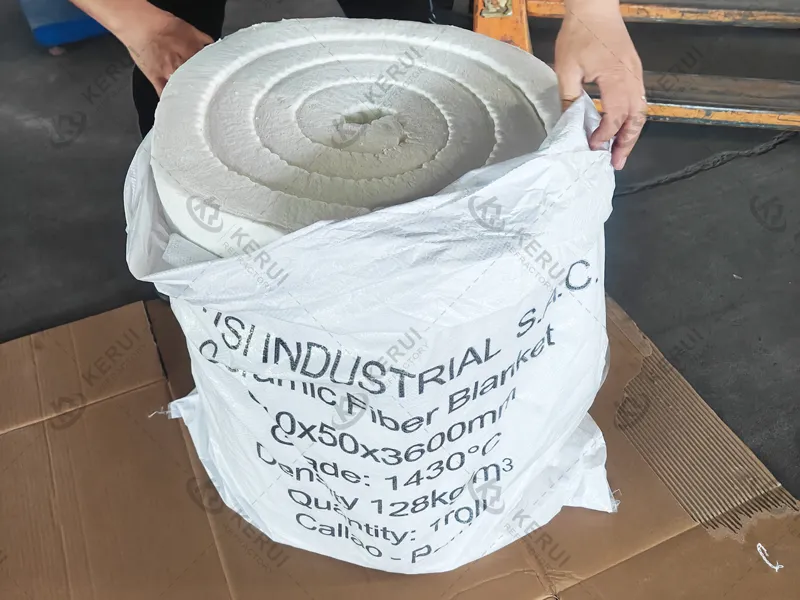

Inspection of Ceramic Fibre Insulation Blanket 25mm at Kerui’s Factory

Kerui’s commitment to quality extends far beyond the production line. Every batch of our 25mm Ceramic Fiber Blanket undergoes a meticulous multi-point inspection by our dedicated Quality Assurance (QA) team before it is approved for shipment.

Our comprehensive inspection protocol includes, but is not limited to:

- Dimensional Accuracy;

- Structural Integrity & Visual Appearance;

- Quantity Confirmation;

- Professional Packaging Assessment.

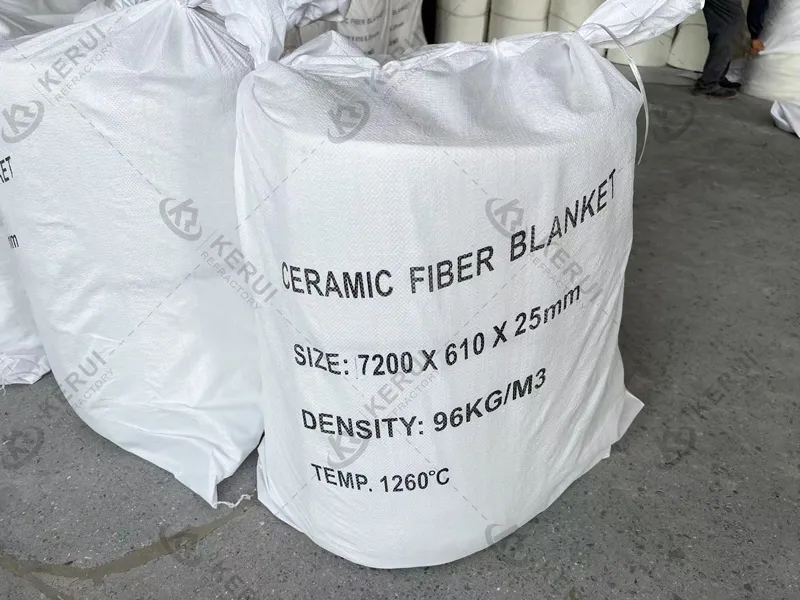

Large Inventory of Standard Sizes of 1′ Ceramic Fiber Blanket

25mm thick ceramic fiber products often comply with ISO and other international standards, facilitating export and project acceptance. To ensure uninterrupted production and project delays, Kerui Refractory maintains a stock of commonly used 25mm thick ceramic fiber blanket core sizes and implements a ready-to-stock mechanism. Currently, the following standard sizes are in stock, ensuring fast delivery:

- Length: 7,200 mm (standard roll length, suitable for most applications);

- Width: 610 mm or 1,220 mm (two popular widths, offering flexible options).

Advantages of 1′ Ceramic Insulation Blanket

- Thermal Insulation: 25mm thickness offers an optimal balance between thermal conductivity (0.085-0.110 W/m·K at 400°C) and heat loss control.

- Excellent Thermal Stability: Withstands temperatures from 1050°C to 1430°C (depending on the material type) without melting, powdering, or losing structural integrity, ensuring stable and reliable performance.

- Excellent Thermal Shock Resistance: The 25mm thickness provides excellent resistance to rapid cooling and heating (such as the frequent start-up and shutdown of industrial furnaces), extending the life of the furnace lining.

- Easy Installation: Compared to thicker gauges (such as 50mm), 25mm blankets are easier to cut and install, making them suitable for stacking multiple layers.

- Economical: Compared to thinner gauges (such as 10mm), a single 25mm layer can meet most medium-temperature requirements, reducing the number of layers and costs.

Kerui Ceramic Fiber Blanket 25mm VS. 50mm

| Comparison Dimension | 25mm Thickness | 50mm Thickness |

|---|---|---|

| Insulation Performance | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Mechanical Strength | Relatively soft and flexible | Higher rigidity and hardness |

| Cost | Cost-effective | Premium |

| Installation & Handling | Excellent flexibility, easy to cut and bend. Ideal for wrapping complex shapes and irregular structures. | Higher rigidity, making it relatively more difficult to cut and form. Better suited for large flat areas or regular curved surfaces. |

| Space Occupancy | Space-saving. The ideal choice for space-restricted areas (e.g., pipe flanges, valves). | Occupies more space, requiring thicker allocated areas for installation. |

| Typical Applications | Hot face lining in industrial furnaces\Pipe and equipment insulation

Expansion joint filling Backing layer for ceramic fiber modules Power boilers |

Hot face lining in industrial furnaces (e.g., smelting furnace walls, roofs)

Areas with high gas velocity or erosion/scouring Projects requiring high energy efficiency High-temperature pipe insulation (especially where higher insulation is required) Equipment and pipes (pipes – term already covered above, can be omitted or kept) |

Standardized Industrial Application Requirements

25mm is a common thickness for industrial furnace and pipe insulation, suitable for most medium- and high-temperature insulation applications. Click YouTube to view some videos.

- Kiln linings: For example, steel heating furnaces and glass kilns.

- Pipe insulation: For example, for high-temperature pipelines in the petrochemical industry.

- Equipment insulation (such as boilers and heat treatment furnaces).

- Steel Industry: Used for ladle covers and heating furnace linings.

- Petrochemical Industry: Used for pipe insulation and reactor insulation.

- Power Industry: Used for boiler and thermal equipment insulation.

Reviews for Kerui 1′ Ceramic Fiber Blankets