Ceramic fiber wool is a high-purity ceramic fiber product. It contains no asbestos or other harmful substances. It is lightweight, flexible, and offers excellent high-temperature insulation and heat resistance. Kerui has provided products and insulation solutions to over 1,000 customers, helping them effectively improve their equipment’s thermal insulation performance and energy efficiency.

- Classification Temperature: 1050-1430ºC;1922-2606°F;

- Bulk Density: 96-160kg/m³; 5-10lbs/cf;

- Length: 7200/3600mm/Customizable;

- Width: 600/610/1220mm/Customizable;

- Thickness: 6-60mm/Customizable;

- Document: MSDS supporting;

- Certificate: ISO9001/ISO14001/OHSAS18001/CE/SGS;

- Shipment: 7-15 working days;

- Accessories: Strip rolling;

- Source: Kerui is the Manufacturer;

Common Forms of Ceramic Fiber Wool

| Types | Ceramic Fiber Cotton | Ceramic Fiber Blanket | Ceramic Fiber Module |

| Forms | Loose, fluffy fibers | Rolled or flat sheets, optionally reinforced with aluminum foil or fiberglass for surface hardness | Pre-compressed blocks or folded structures |

| Installation | Free filling or spray application | Cut and wrapped, layered, or mechanically fixed | Anchored with pins for rapid assembly |

| Applications | – Insulation for high-temperature pipes/valves – Expansion joint filling in furnace shells and refractory bricks – Spray-applied boiler linings (requires special equipment) |

– Insulation wrapping for petrochemical pipes and thermal equipment – Backing insulation for electric furnaces and aluminum melting furnaces – Removable insulation covers for high-temperature flanges and valves |

– Full fiber linings for large kilns (cement, glass furnaces) – Roof and sidewall insulation for heat treatment furnaces – High-temperature linings for chemical reactors |

Basic Parameters of Ceramic Fiber Wool

| Item | Common Type | Standard Type | High Purity Type | High Alumina Type | Zirconium Containing Type |

|---|---|---|---|---|---|

| Classification Temperature, ℃ | 1050 | 1260 | 1260 | 1350 | 1430 |

| Service Temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Bulk & Density, kg/m³ | 96-128 | 96-128 | 96-128 | 128-160 | 128-160 |

| Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) | -3 (1250℃) | -3 (1350℃) |

| Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) 0.22 (1000℃) | 0.132 (600℃) 0.22 (1000℃) | 0.76 (800℃) 0.20 (1000℃) |

| Strength of Extension, Mpa | 0.08-0.12 | ||||

| Al2O3, % | 44 | 46 | 47-49 | 52-55 | 39-40 |

| Al2O3+SiO2, % | 96 | 97 | 99 | 99 | - |

| Al2O3+SiO2+ZrO2, % | - | - | - | - | 99 |

| ZrO2, % | - | - | - | - | 15~17 |

| Fe2O3, % | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

| Size, mm | Standard Size: 7200/3600*610/1220*6-60; Customized Sizes | ||||

Different Kinds of Ceramic Wool for Sale

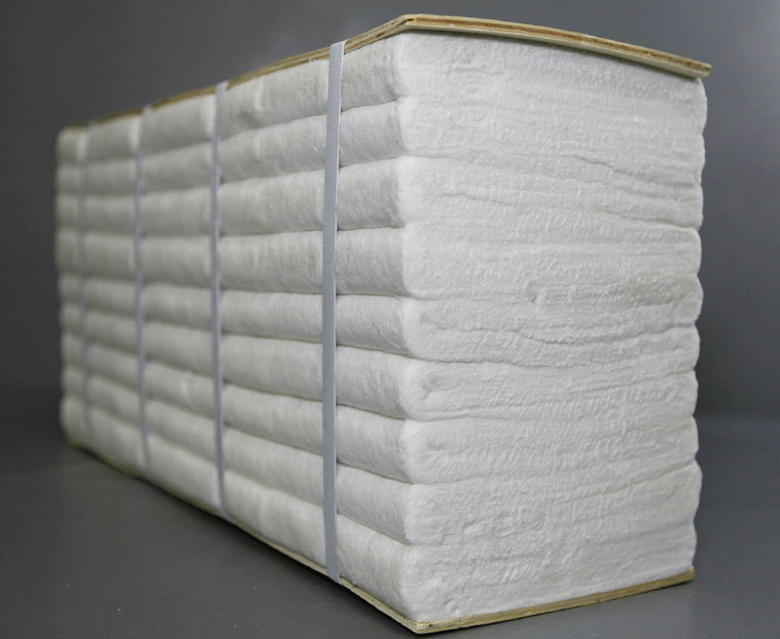

Kerui ceramic fiber wools come in various types, including standard ceramic blanket, single-sided foil wools, and double-sided foil wools. We can also provide corresponding accessories such as hold-in-place straps.

- Standard wools can meet the high-temperature requirements of most applications.

- Wools with foil are suitable for applications that require higher reflective insulation and flame retardancy.

Unique Features of Kerui Ceramic Wool Insulation

- High temperature resistance;

- Excellent thermal shock resistance;

- Good corrosion resistance;

- High tensile strength;

- Low thermal conductivity;

- Lightweight;

- Easy to cut construction.

Custom Ceramic Fiber Wool Solutions Tailored to Your Needs

We understand that every industrial application has unique requirements. That’s why we offer fully customizable ceramic fiber wool solutions to meet your exact specifications. Customization options include:

- Density Variations (80-220 kg/m³): Optimize for thermal efficiency or mechanical strength.

- Temperature Grades (1,260°C to 1,600°C): Select the perfect heat resistance level.

- Specialized Formats: Choose from loose wool, pre-cut blankets, or modular blocks.

- Reinforcement Options: Add aluminum foil, glass fiber mesh, or stainless steel wire for enhanced durability.

- Size & Shape Cutting: Precision-cut to your dimensional requirements.

Different Requirement for Ceramic Fiber Wool Insulation

Refractory wools come in various specifications to suit different applications and requirements. Consult Kerui for tailored recommendations.

- Thickness, height, and width: The final application quantity varies based on the dimensions of each wool roll. Kerui can provide professional recommendations on the required quantity;

- Operating temperature: Different kiln temperatures affect the wool’s lifespan. Choose the most suitable operating temperature;

- Materials: Besides regular ceramic fiber wools for sale, Kerui also offers soluble fiber and alumina fiber products.

Uses of Kerui Refractory Wool in High Temperature Kilns

- Industrial Furnaces: This material is used as furnace linings and insulation layers in various industrial furnaces. It can increase furnace temperature and reduce energy consumption.

- Pipe and Chimney Insulation: It is used for insulating high-temperature pipes and chimneys, helping to reduce heat loss.

- High-Temperature Equipment Insulation: The ceramic wool for sale is used for sealing and insulating high-temperature valves, flanges, and gaskets.

- High-Temperature Filtration: It is used for filtering high-temperature gases.

Top Choice of Ceramic Fire Wool is Kerui Refractory

Kerui’s ceramic wool fire insulation is exported to over 50 countries, including Korea, the UAE, Saudi Arabia, Turkey, and Japan. These customers not only repurchase from us but also maintain long-term partnerships.

These are some cases for shipping to the global world.

- Packaging: 1 roll/1 bag; 2 rolls/1 bag; 1 roll/1 box;

Ceramic Fiber Wool VS. Rookwool

| Material | Pros | Cons |

| Ceramic Fiber | – Extreme heat resistance | – Dust hazards (RCF) |

| – Lightweight, flexible | – Higher cost than Rockwool | |

| Rockwool | – Better soundproofing | – Lower temp limit (~1000°C) |

| – Eco-friendly, recyclable | – Heavier, less flexible |

Why Choose Ceramic Fire Wool from Kerui Refractory

Many customers choose to cooperate with Kerui and maintain long-term partnerships due to our high-quality products and professional services.

- OEM Manufacturing: Kerui has its own manufacturing facilities.

- Engineering Support: Our technical team helps select optimal specifications.

- Advanced Equipment: We possess advanced production equipment, such as needle-punched ceramic glass wool production lines.

- Fast Delivery: Get samples within 72 hours for approval.

- Professional Technical Team: Kerui’s technical team can recommend suitable products, quantities, and applications based on customers’ usage environments.

- Volume Flexibility: No minimum order quantity for custom solutions.

- Certified Quality: Our products have obtained certifications such as ISO, SGS, DNV, BV, ABS, GL, NK, LR, AEO, REACH, CE ASTM.

- Excellent Services: Technical guidance, drawing and construction guidance are available.

Contact Kerui Refractory

Kerui is the manufacturer of ceramic fiber wool. We offer factory price, high quality, large capacity, and quick delivery. If you need this product, contact us now for details! View YouTube to see more videos.