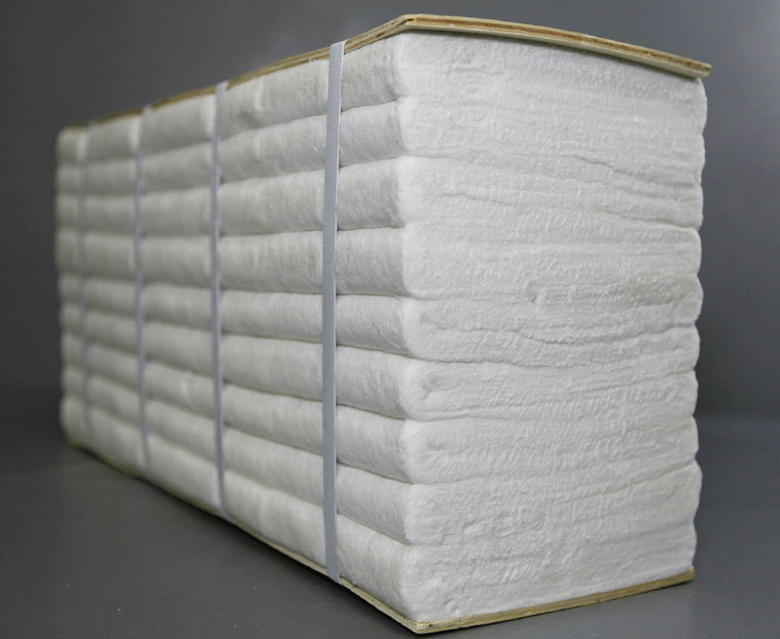

Ceramic fiber module is a ceramic fiber product with good thermal insulation performance. This modular design can help simplify and process the construction of the entire high-temperature application. The performance of this product also varies depending on the size and thickness. Kerui Refractory offers a variety of products for customers to choose from.

- Al2O3: ≥35-52%;

- SiO2: ≥47-55%;

- Bulk Density: 160-220g/cm³;

- Permanent Liner Change: 2.5-3.0%;

- Thermal Conductivity Coefficient: 0.1-0.27W/(m·K);

Technical Specifications of Kerui Ceramic Fiber Module

| Item/Grade | STD MODULE | HP MODULE | HA MODULE | HZ MODULE | |

|---|---|---|---|---|---|

| Classification Temperature/℃ | 1260 | 1260 | 1350 | 1430 | |

| Chemical Composition | ω (Al2O3) ≥/% | 43 | 44 | 52 | 35 |

| ω (SiO2) ≥/% | 54 | 55 | 47 | 49 | |

| ω (ZrO2) ≥/% | / | / | / | 15 | |

| Color | White | White | White | White | |

| Bulk Density (kg/m³) | 160-220 | 160-220 | 160-220 | 160-220 | |

| Permanent Linear Change ≤/% | 1000℃*24h 2.5 | 1100℃*24h 2.5 | 1200℃*24h 3.0 | 1350℃*24h 3.0 |

|

| Thermal Conductivity Coefficient/[W/(m·K)] | 400℃ | 0.1 | 0.1 | 0.1 | 0.1 |

| 600℃ | 0.18 | 0.17 | 0.16 | 0.15 | |

| 800℃ | 0.2 | 0.2 | 0.2 | 0.19 | |

| 1000℃ | 0.27 | 0.26 | 0.26 | 0.26 | |

Different Structure of Ceramic Fiber Module

| Type | Structural Features | Typical Applications |

|---|---|---|

| Z-Block Insulation | Z-folded, pinned anchoring | Petrochemical heaters, roller hearth furnaces |

| U-Shaped Module | U-folded, ceiling-mounted installation | Tunnel kiln ceilings, glass melting furnaces |

| Locking Plate Type | Metal plate mechanical fixation | Metallurgical heating furnaces, vibrating equipment |

| Mack-Type Module | Multi-layer stacking, adaptable to complex shapes | Chemical reactors, specialty ceramic kilns |

| Hard-Soft Composite | Hard + soft composite structure | Aluminum processing furnaces, high-temperature heat treatment |

| Non-Folded Type | Integral compression, high density | RTO incinerators, flue lining |

| Combination Z-Type | Multi-anchor combined installation | Cracking furnaces, continuous annealing furnaces |

Description of Refractory Module

Ceramic fiber modules are manufactured through a process of needle-felting ceramic fiber insulation blanket followed by further processing. This process results in ceramic fiber modules with uniform density and no gaps. These modules are easy to install and have strong mechanical resistance. Additionally, their excellent thermal insulation properties can bring high energy efficiency to high-temperature industries. Kerui Refractory can customize exclusive products for partners according to their construction conditions and application fields.

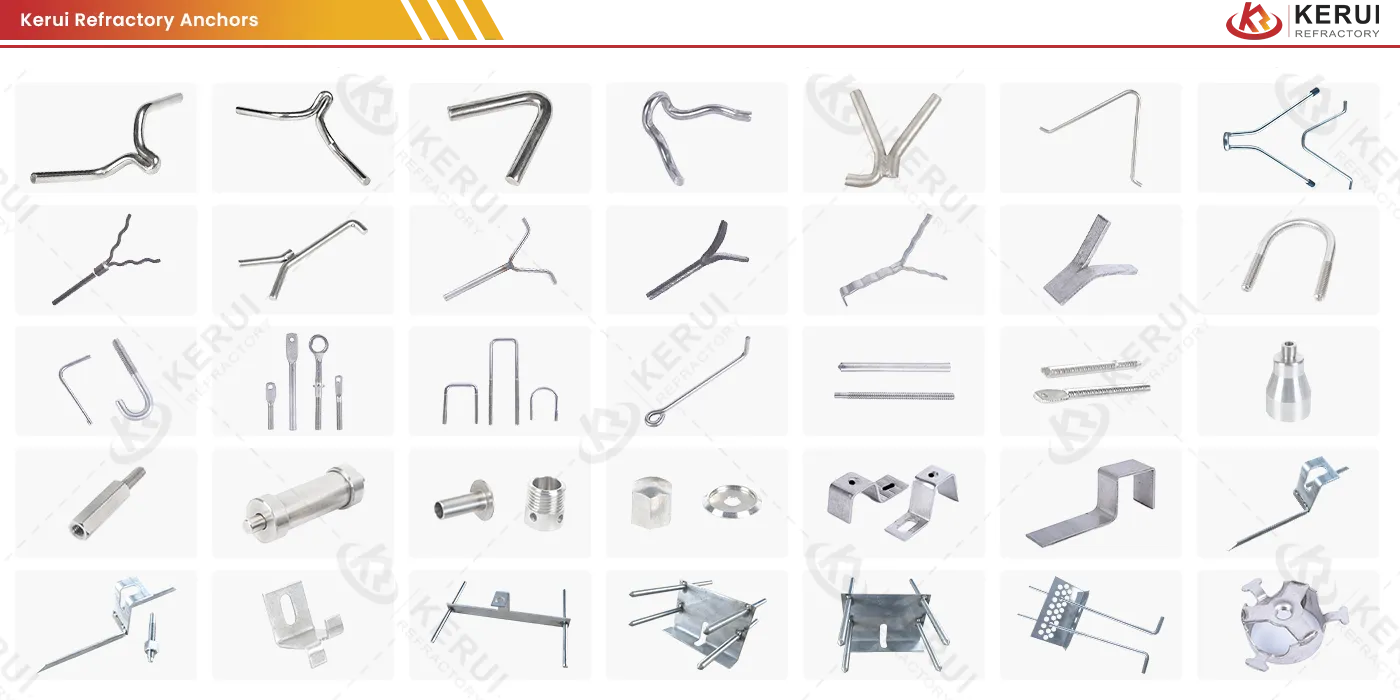

Matching Products – Ceramic Fiber Anchors

Noted: Find ceramic fiber refractory anchors options here.

Key Features of Kerui Insulation Fibre Module

- High fire resistance: Ceramic fiber modules can withstand extreme temperatures ranging from 1260°C to 1460°C (2300°F to 2660°F) without melting or burning. This makes them an ideal choice for fire protection applications in high-temperature environments.

- Low thermal conductivity: These modules have a low thermal conductivity. This means they effectively resist heat transfer.

- Strong resistance to thermal shock: This product is resistant to thermal shock due to their low thermal expansion coefficient. This means they can withstand rapid temperature fluctuations without losing their structural integrity.

- Strong chemical stability: Ceramic fiber module-module insulation is chemically stable and resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes them suitable for use in harsh environments with aggressive chemicals.

- High abrasion resistance: The interlocking crystal structure of ceramic fibers provides them with excellent abrasion resistance. This means they can withstand wear and tear from abrasive materials. This makes them suitable for use in applications where they may be subjected to friction or mechanical abrasion.

- Easy installation: Ceramic fiber modules are lightweight and flexible. This makes them easy to handle and install. They can be cut to size and shaped to fit various applications.

Industry Applications of Ceramic Fiber Folding Module

This product features excellent performance. This material serves as a widely used insulation solution for furnace linings, with primary applications in the following industries:

- Iron and steel smelting: Steelmaking furnaces, blast furnaces, open-hearth furnaces, converters, etc.

- Non-ferrous metal smelting: Smelting furnaces, heat storage chambers, etc.

- Building materials: Ceramic kilns, glass kilns, cement kilns, lime kilns, etc.

- Petrochemicals: Coke ovens, heat treatment furnaces, reactors, etc.

Shipment of Fiber Folding Module

Ceramic fiber modules are used in many countries, including Belarus, Peru, Indonesia, Oman and other countries. See more YouTube videos here.