Ceramic Fiber Insulation Blanket

Ceramic fiber insulation blanket is an insulation material made of harmless ceramic fibers. It is lightweight and has low thermal conductivity. Kerui has exported this product to 50+ countries, including Russia, Indonesia, South Korea, Vietnam, Jordan, Saudi Arabia, etc. We offer standard (normal, single-sided foil faced, and double-sided foil faced) & customized products to these partners.

- Free Sample:

- Available

- Document:

- MSDS supporting

- Performance Test:

- Support

- Shipment:

- 7-15 working days globally

Parameters of Kerui Ceramic Fiber Blanket for Sale

Kerui Offers the Following Hot Sizes

- Length: 3600 (141-142″)/7200mm (283-284″)/Customizable

- Width: 600 (23-24″)/610 (24″)/1220mm (48″)/Customizable

- Thickness: 6-60mm/Customizable. Hot thicknesses are 25mm/1″ and 50mm/2″

- Color: SW Standard White

| Item | Common Type | Standard Type | High Purity Type | High Alumina Type | Zirconium Containing Type |

|---|---|---|---|---|---|

| Classification Temperature, ℃ | 1050 | 1260 | 1260 | 1350 | 1430 |

| Service Temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Bulk & Density, kg/m³ | 96-128 | 96-128 | 96-128 | 128-160 | 128-160 |

| Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) | -3 (1250℃) | -3 (1350℃) |

| Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) 0.22 (1000℃) | 0.132 (600℃) 0.22 (1000℃) | 0.76 (800℃) 0.20 (1000℃) |

| Strength of Extension, Mpa | 0.08-0.12 | ||||

| Al2O3, % | 44 | 46 | 47-49 | 52-55 | 39-40 |

| Al2O3+SiO2, % | 96 | 97 | 99 | 99 | - |

| Al2O3+SiO2+ZrO2, % | - | - | - | - | 99 |

| ZrO2, % | - | - | - | - | 15~17 |

| Fe2O3, % | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

| Size, mm | Standard Size: 7200/3600*610/1220*6-60; Customized Sizes | ||||

Note: Asbestos Free.

Besides, Kerui offers soluble fiber blanket and a polycrystalline mullite fiber blanket. If you have any needs, please contact us.

Different Types of Insulation Blanket for Your Selection

In addition to ceramic fiber blankets, Kerui Refractory also provides other types of insulation blankets to meet the insulation needs of customers’ industries.

| Feature | Ceramic Fiber Blanket | Silica Alumina Blanket | Soluble Fiber Blanket | Polycrystalline Mullite Fiber Blanket |

|---|---|---|---|---|

| Main Composition | Mainly aluminum silicate | Silica alumina with other oxides | Soluble calcium or magnesium silicate | Mainly mullite (aluminum silicate) |

| Temperature Range | 1260°C – 1430°C | 1260°C – 1430°C | 700°C – 1100°C | 1300°C – 1600°C |

| Density | Low (96-160 kg/m³) | Low (96-160 kg/m³) | High (64-500 kg/m³) | Medium (150-250 kg/m³) |

| Insulation | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Chemical Resistance | Good, acid and alkali resistant | Good resistance to acids and alkalis | Sensitive to acids, better against alkalis | Excellent acid and alkali resistance |

| Applications | High-temperature kilns, metallurgy, chemicals | Boilers, pipes, high-temperature pipelines | Low-temperature applications like casting | High-temperature kilns, steel, power, ceramics |

| Environmental Impact | No asbestos | No asbestos | Non-toxic and eco-friendly | No harmful substances, eco-friendly |

| Durability | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

Free Sample of Kerui Ceramic Blanket to Customers

Kerui Refractory offers free samples for customers to check whether the quantity meets their requirements. This is one of the samples shipped to a customer. We use a box to pack. Finally, this customer is satisfied with Kerui ceramic fiber products.

- Thickness of A Sample: 50mm;

- Operation: Easy to cut.

High-quality Production of Kerui Ceramic Insulation Blanket for Sale

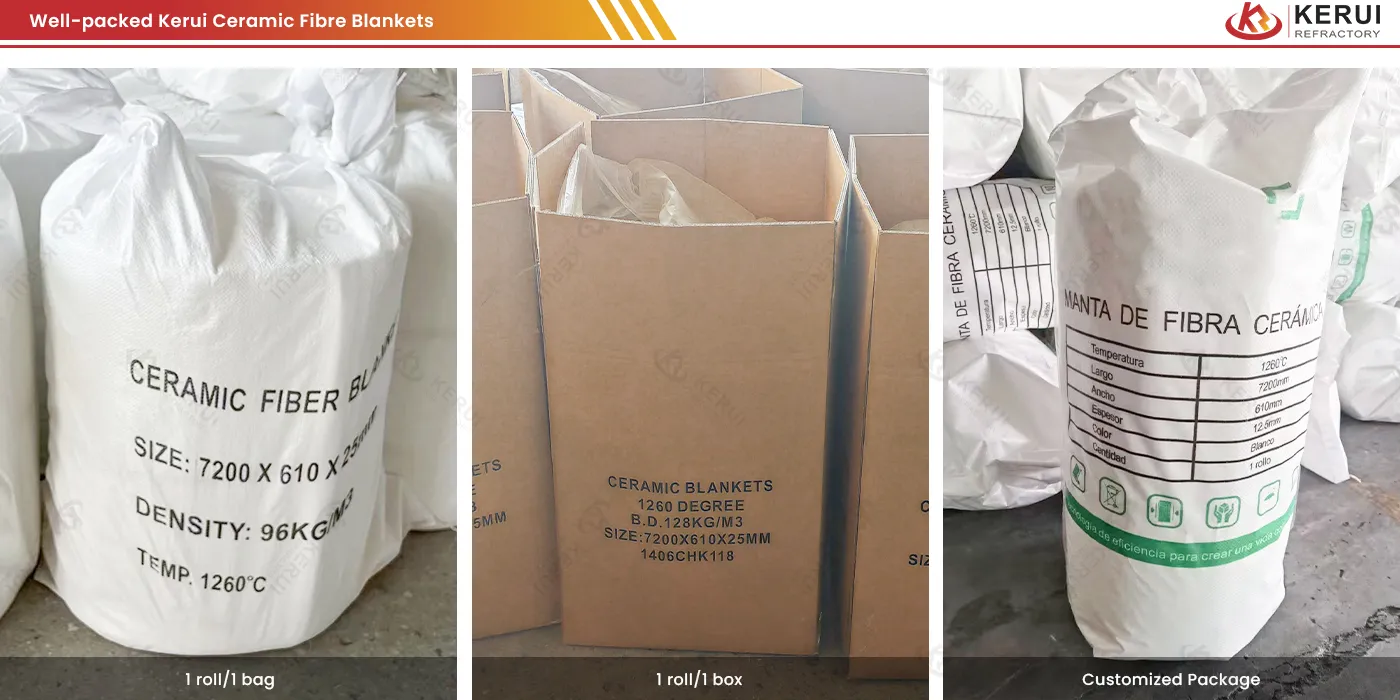

Well-packed Kerui Ceramic Fibre Blankets

Kerui provides multiple packaging options to meet various customer needs, including custom packaging services. Contact us with your requirements.

- Packaging: 1 roll/1 bag; 2 rolls/1 bag; 1 roll/1 box;

- Price: Low factory price; Confirming shipping fees later.

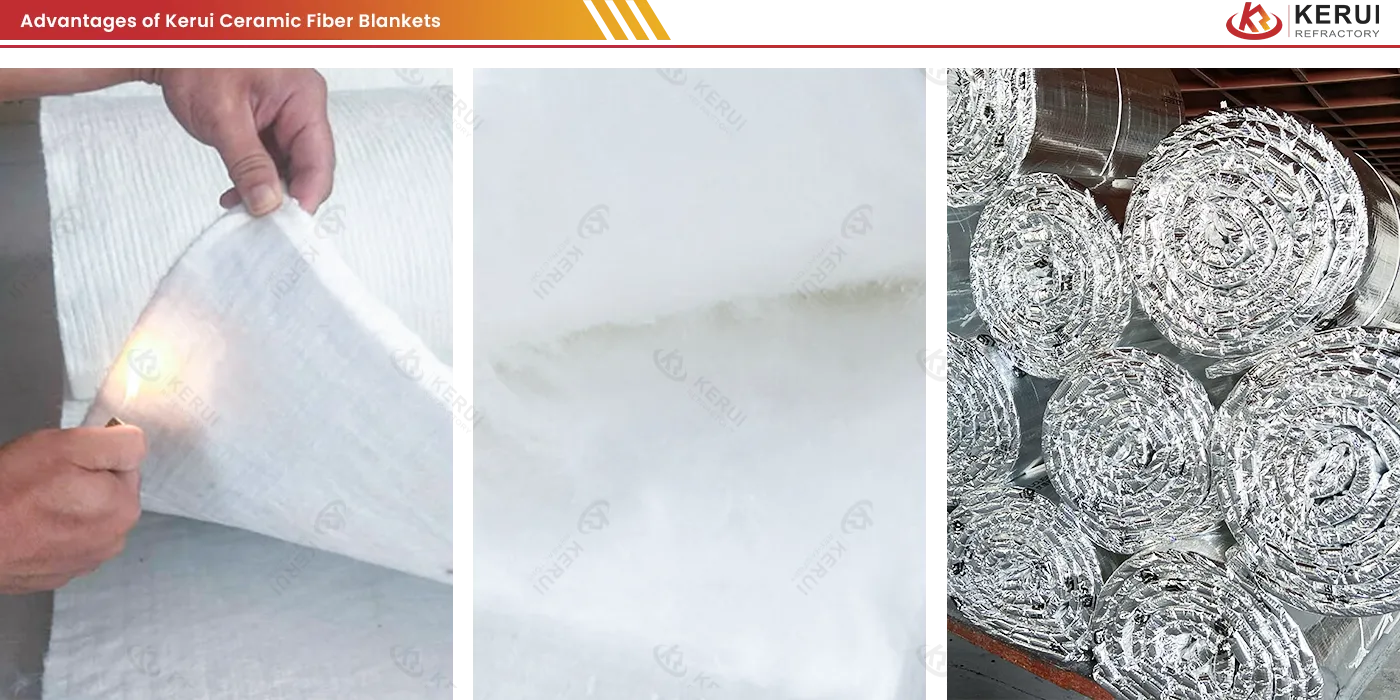

Advantages of Kerui Ceramic Fiber Blankets

![]()

![]()

![]()

![]()

![]()

![]()

Typical Applications of Kerui Kiln Insulation Blankets

This high-performance ceramic fiber product is specifically engineered for superior thermal insulation and sealing in extreme temperature environments. Finally, it is ideal for a wide range of industrial applications, including:

- Iron & Steel Metallurgy: Blast furnace/hot blast stove insulation; Ladle/tundish covering agent;

- Non-ferrous Metal Smelting: Aluminum electrolytic cell lining; Copper smelting furnace expansion joint filling;

- Petrochemical Industry: Cracking furnace lining; Steam pipeline insulation;

- Power Industry: Gas turbine heat shield; Boiler hot-face sealing;

- Cement Industry: Rotary kiln preheating zone insulation; Grate cooler high-temperature zone insulation;

- Glass Industry: Glass melting furnace crown insulation; Tin bath upper zone insulation; etc.

2000+ Partners Choose Kerui Ceramic Fiber Blanket

Our customers come from more than 50 countries, including Russia, the Philippines, Malaysia, Saudi Arabia, the United Arab Emirates, Oman, Morocco, and so on. Many of our cooperative customers have chosen to work with us long-term. Finally, they have expressed high praise for our aluminum silicate fiber products and services.

![]()

![]()

![]()

![]()

![]()

Indonesia

![]()

![]()

![]()

Video of Kerui Ceramic Blanket Fibre

This video shows high-temperature ceramic blankets, covering their features, types, specifications, certificates, production, delivery, and customers. Moreover, it demonstrates Kerui’s production strength and high-quality products. If you have a large requirement, contact us right now.

Top Choice of Ceramic Fiber Blanket Supplier – Kerui Refractory

OEM manufacturer of ceramic wool blankets;

Large and stable production volume;

Strict manufacturing process and quality guarantee;

Standard products and customized products;

Multiple international certificates, patent certificates and product quality inspection reports;

![]()

Insulation solutions according to the use conditions;

Professional proposal for product selection;

In-stock and fast delivery;

Construction guidance services for Kerui ceramic fiber insulation blanket roll.

After-sales technical consulting services. See some YouTube videos.