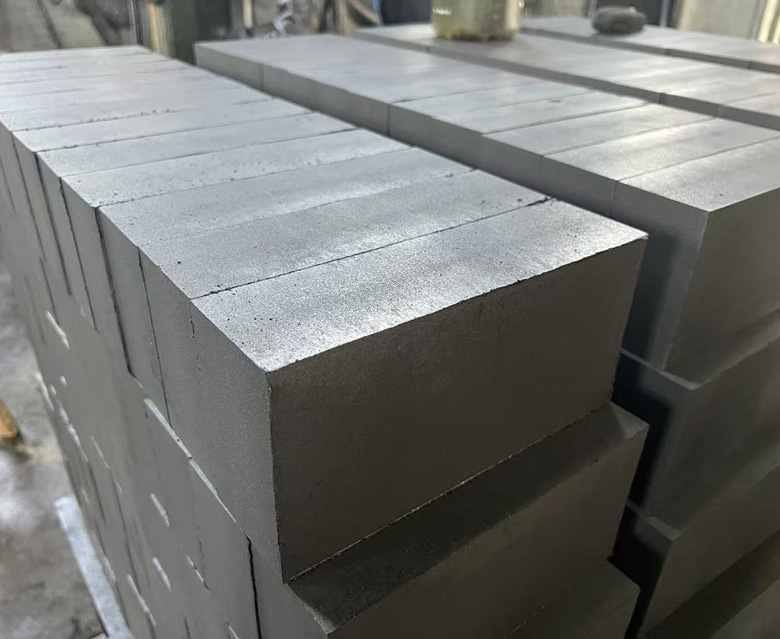

Carbon brick shows excellent stability in extreme chemical environments and high temperature conditions as a high-performance anti-corrosion solution. Kerui, as a manufacturer, provides bricks of various specifications.

- Bulk Density: ≥1.5-1.65g/cm³;

- Flexural Strength: ≥15-2MPa;

- Apparent Porosity: <10-22%;

- Ash Content: ≤2-5%;

- Size: Standard/And other sizes;

Parameters of Kerui Carbon Bricks

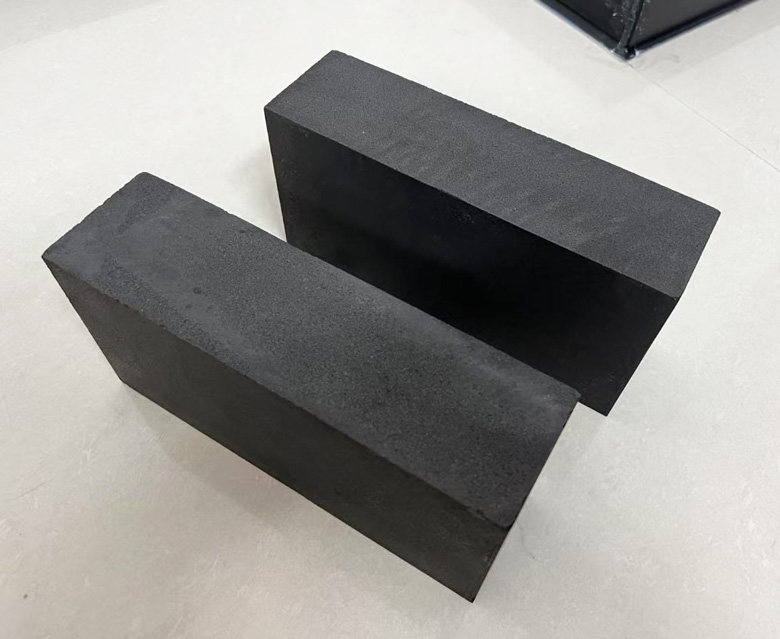

Anti-corrosion carbon bricks are carbon refractory materials made of graphite, coke or anthracite as the main raw materials. And it is supplemented by organic binders (such as tar pitch, phenolic resin, etc.). High-purity carbon materials (fixed carbon ≥88%) are preferred. Please see the parameters:

| Property | Sintered Carbon Brick | Pressed Carbon Brick | ||

|---|---|---|---|---|

| Type | SJ-2 | SJ-1 | YZ-2 | YZ-1 |

| Bulk Density (g/cm³) | ≥1.5 | ≥1.65 | ≥1.6 | ≥1.65 |

| Flexural Strength (MPa) | ≥15 | ≥20 | ≥15 | ≥20 |

| Compressive Strength (MPa) | ≥45 | ≥65 | ≥50 | ≥70 |

| Thermal Conductivity (W/(m·K)) | 2.0-8.0 | 2.0-8.0 | 2.0-8.0 | 2.0-8.0 |

| Ash Content (%) | ≤5 | ≤3 | ≤5 | ≤2 |

| Elastic Modulus (10⁴N/mm²) | 0.5-1.5 | 0.5-1.5 | 0.5-2.5 | 0.5-2.5 |

| Linear Expansion Coefficient (10⁻⁶/K) | 3.0-4.0 | 3.0-4.0 | 3.5-5.0 | 3.5-5.0 |

| Apparent Porosity (%) | <22 | <20 | <15 | <10 |

Specifications Of Kerui Carbon Bricks

The standard specifications of anti-corrosion carbon bricks cover the range of 400×400×400mm to 1800×800×800mm, meeting most industrial needs. Customized services can be provided for special application scenarios:

- Special-shaped bricks: including arc refractory bricks (for reactors, towers), trapezoidal bricks (for conical equipment), wedge bricks (vault structures), etc., with a minimum processing accuracy of ±0.5mm.

- Extra large size: By improving the molding process, the maximum single block size can reach 2000×1000×1000mm, reducing the number of joints and improving the reliability of corrosion protection.

Resin Impregnated Anti-corrosion Carbon Bricks

Advantages Of Anti-Corrosion Carbon Bricks

This brick uses the high stability of carbon materials and the impermeability of binders to form a protective layer against acid, alkali and salt erosion.

Chemical Stability

- High acid resistance: Good carbon bricks offer exceptional acid resistance (≥99.8%), even against harsh chemicals like hydrofluoric and hot phosphoric acids. Test results demonstrate less than 0.3% mass loss after 30 days in 80℃, 50% sulfuric acid.

- Strong impermeability: Resin impregnation cuts carbon brick porosity below 5%, slashing corrosion risks. Mercury tests show pore size shrinks from 5μm to under 0.1μm post-treatment.

- Strong oxidation resistance: In 600℃ air, the oxidation weight loss rate of anti-oxidation treated carbon bricks is <0.5g/(m²·h), which is 3-5 times higher than that of ordinary carbon bricks.

Good Thermal Performance

- High thermal conductivity: The wide range of 2.0-8.0 W/(m·K) makes it suitable for both insulation and heat transfer elements. The higher the graphite content, the better the thermal conductivity.

- Low thermal expansion coefficient: The linear expansion coefficient of 3.0-5.0×10⁻⁶/K is much lower than that of most refractory materials, ensuring dimensional stability during temperature changes.

- Strong thermal shock resistance: High-quality carbon bricks can endure over 20 cycles of 1000℃→water cooling without cracking. A steel plant’s experience shows that with temperature fluctuations of 300℃/h, the carbon brick lining lasts over 5 years.

Economy and Sustainable Development

- Life cycle cost: Although the initial investment is 2-3 times higher than that of ordinary products, the service life is extended by 5-8 times, and the comprehensive cost is reduced by more than 40%.

- Maintainability: Local damage can be repaired on-site with special repair materials without overall replacement.

- Environmental protection: It does not contain harmful substances such as heavy metals, and waste bricks can be crushed and used as fuel to achieve resource recycling.

Application Of Anti Corrosion Carbon Bricks

- Application in strong acid environment: pickling tank in fertilizer plant

- Application in high-temperature industrial furnace: aluminum electrolytic cell, calcium carbide furnace, garbage incinerator

- Special working condition solutions: high-pressure reactor, high-speed flow channel, etc.

Use Of Anti Corrosion Carbon Bricks

- Joint treatment: Installers maintain joint widths at 3–5mm and fill them with special acid-resistant glue. For mobile equipment, they reserve a 1–2mm thermal expansion gap.

- Anchoring system: Different anchoring methods are designed according to the flow rate of the medium: resin can be used for low-speed environment (<3m/s); acid-resistant alloy anchors are required for high-speed scouring environment.

- Impermeability layer design: The multi-layer structure features: a surface 2-3mm resin sealing layer + a main carbon brick layer + a bottom elastic buffer layer, effectively blocking the penetration path.

Delivery of Carbon Brick to 20+ Countries

Kerui proudly supplies high-performance anti-corrosion carbon bricks to over 20 countries across five continents, serving critical industries such as metallurgy, chemical processing, and power generation. With efficient global logistics, we ensure on-time delivery in secure packaging, whether by sea, air, or land freight. Custom specifications and bulk order discounts are available to meet your project requirements.

Contact Kerui for Your Carbon Brick

As the core material in the field of industrial corrosion protection, the value of anti-corrosion carbon bricks has been verified in many harsh environments. Correct material selection, system design and standardized construction can extend the service life of carbon brick lining to more than 10 years. Kerui provides high-quality products, professional services and precise solutions to improve efficiency for customers. Take a view at Kerui Pinterest for more pictures.